Direct-drive electro-hydraulic actuator

A technology for driving electricity and actuators, which is applied to fluid pressure actuators, fluid pressure actuator system components, mechanical equipment, etc. It can solve problems such as low reliability, inability to eliminate, and vibration of oil pipelines to improve work performance , high flexibility, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

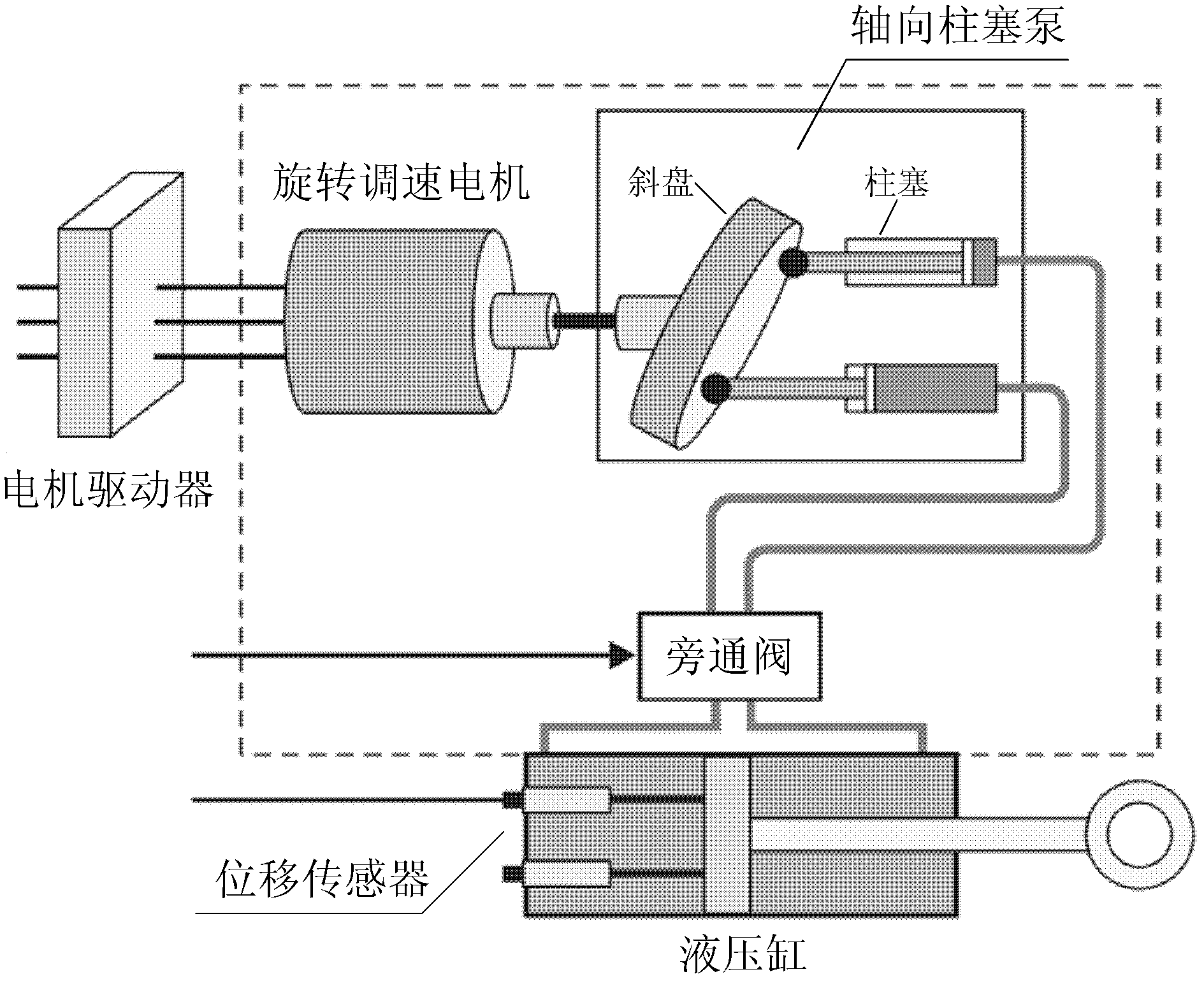

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

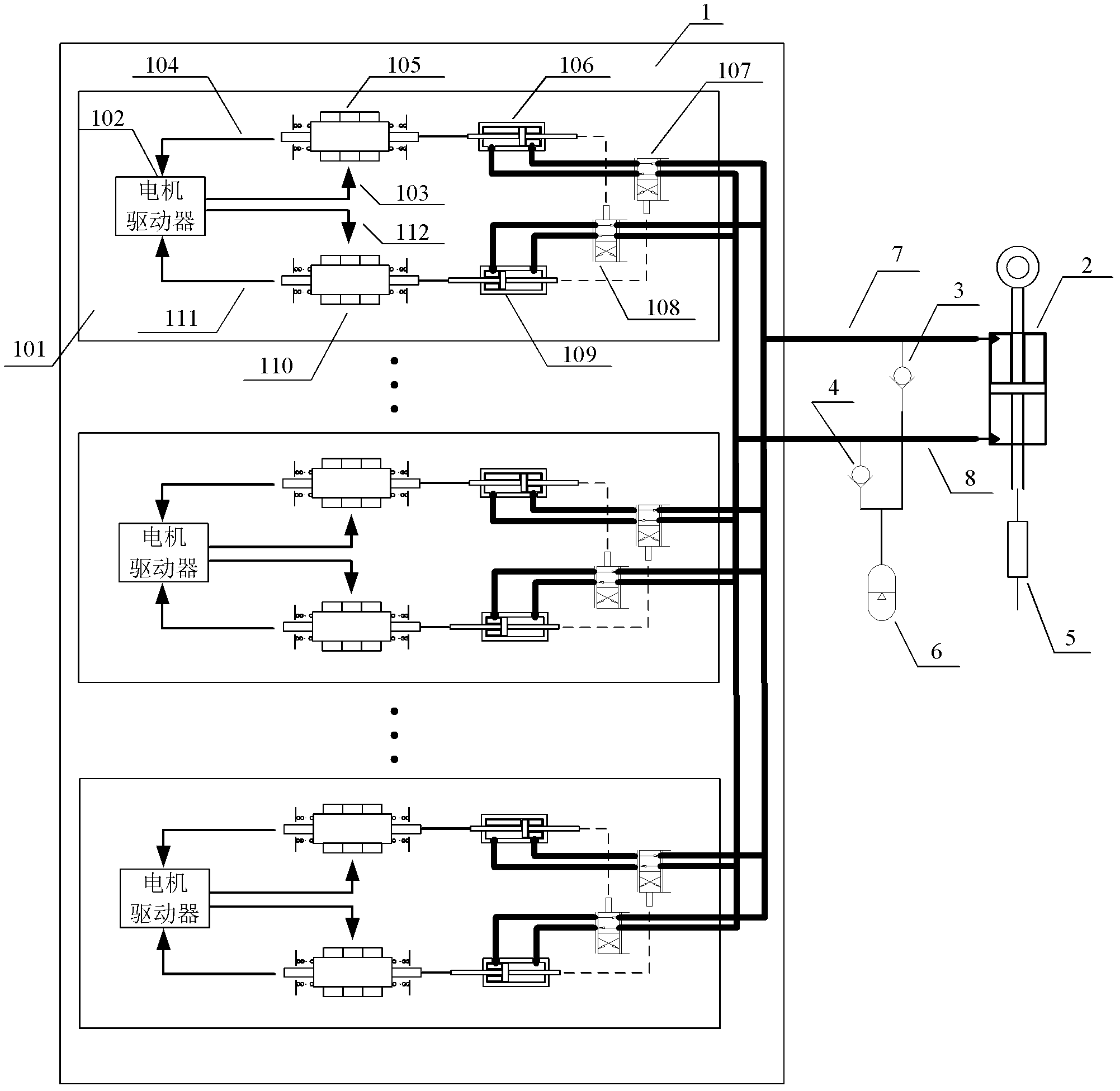

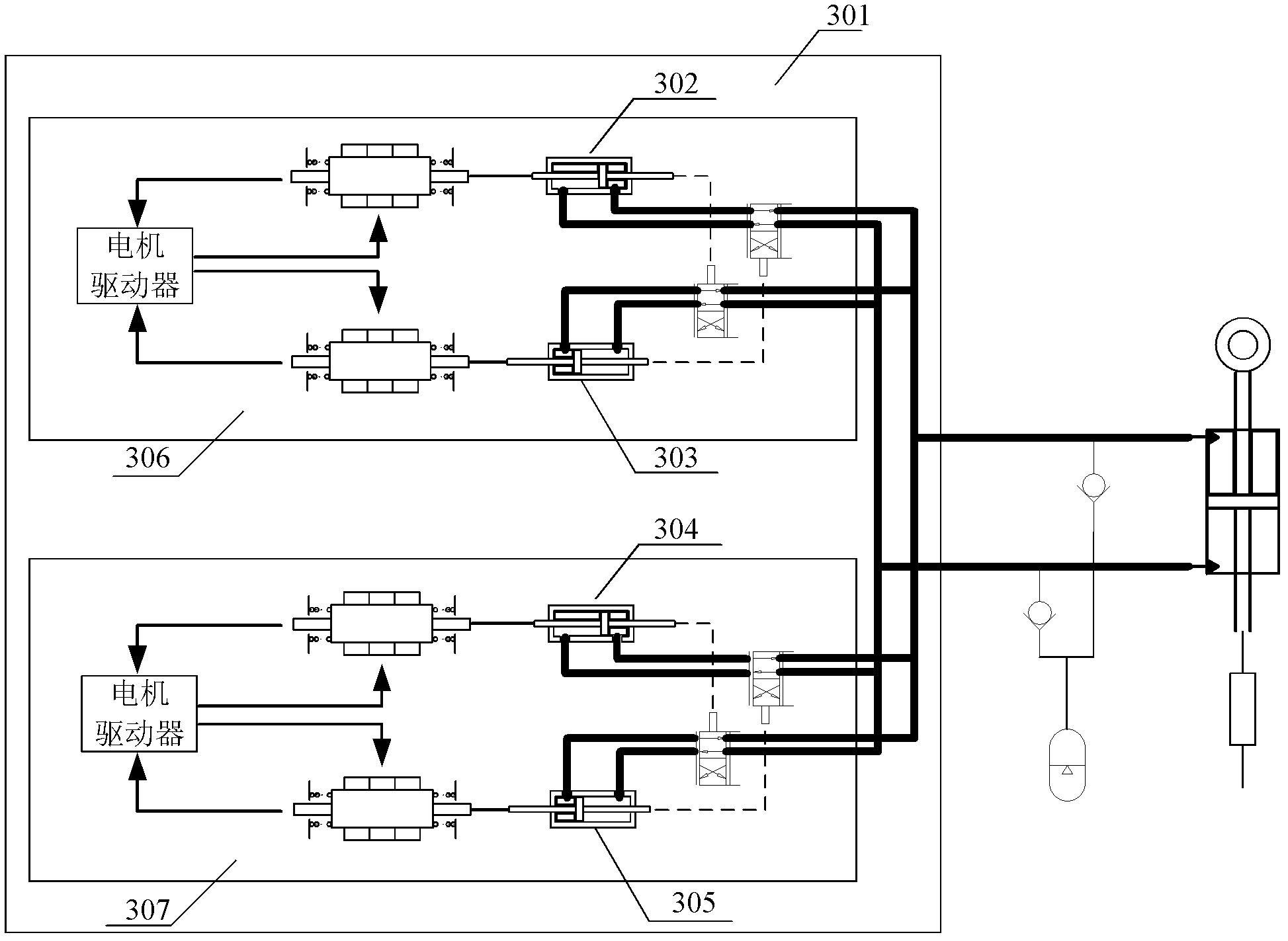

[0036] The present invention is a direct drive electrohydrostatic actuator, such as figure 2 As shown, it includes a direct drive electro-hydraulic servo pump 1, a pressurized oil tank 6, a first oil supply check valve 3, a second oil supply check valve 4, and a hydraulic cylinder 2, and its core component is a direct drive electro-hydraulic servo pump 1 .

[0037] The direct drive electro-hydraulic servo pump 1 includes a plurality of oil supply modules 101, and each oil supply module 101 has the same structure; the oil supply module 101 includes a motor driver 102, a first linear oscillating motor 105, a second linear oscillating motor 110, The first oil suction and discharge piston 106 , the second oil suction and discharge piston 109 , the first distribution valve 107 and the second distribution valve 108 .

[0038] The motor driver 102 receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com