Compact swash plate type electric proportional axial plunger pump and control method thereof

A technology of axial plunger pump and electric proportional control valve, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the problem of restricting the miniaturization of plunger pumps, unfavorable installation and transportation of construction machinery, and unfavorable construction machinery. Miniaturization requirements and other issues, to achieve the effect of strong anti-interference ability and reduce the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

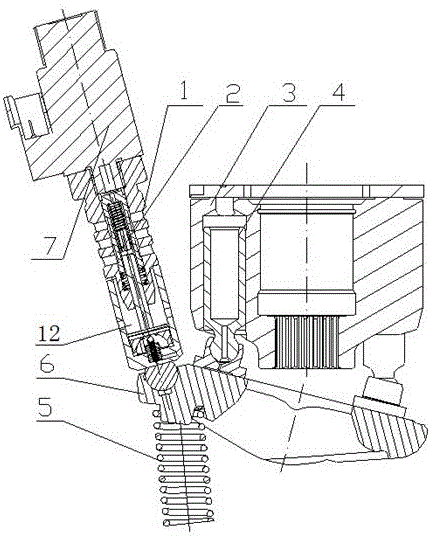

[0021] Example. A compact swash plate electric proportional axial piston pump consisting of figure 1 As shown, it includes the electric proportional control valve 1 and the pump body, the electric proportional control valve 1 is connected with the proportional electromagnet 7, the pump body is connected with the swash plate 6, the electric proportional control valve 1 is set on one side of the swash plate 6, and the swash plate 6 There is a return spring 5 on the other side of the electric proportional control valve 1 . The pump body generally includes a rotor 3 and a plunger 4 .

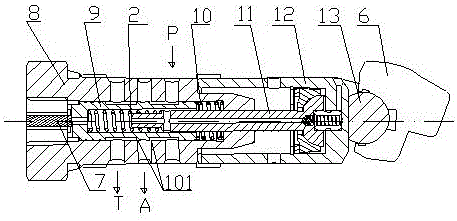

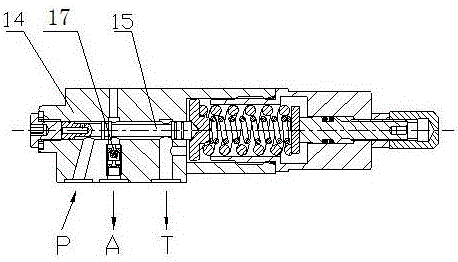

[0022] The electric proportional control valve 1 is constituted as figure 2 As shown, it includes an electric proportional valve sleeve 8, the outer end of the electric proportional valve sleeve 8 is provided with a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com