Unidirectional hydraulic axial variable displacement plunger pump

An axial plunger pump and plunger pump technology, which is applied to liquid variable capacity machinery, pumps, multi-cylinder pumps, etc., can solve the problems of low utilization rate of motive power, unsatisfactory energy saving effect, and poor system reliability. To achieve the effect of simple structure design, fast action response and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

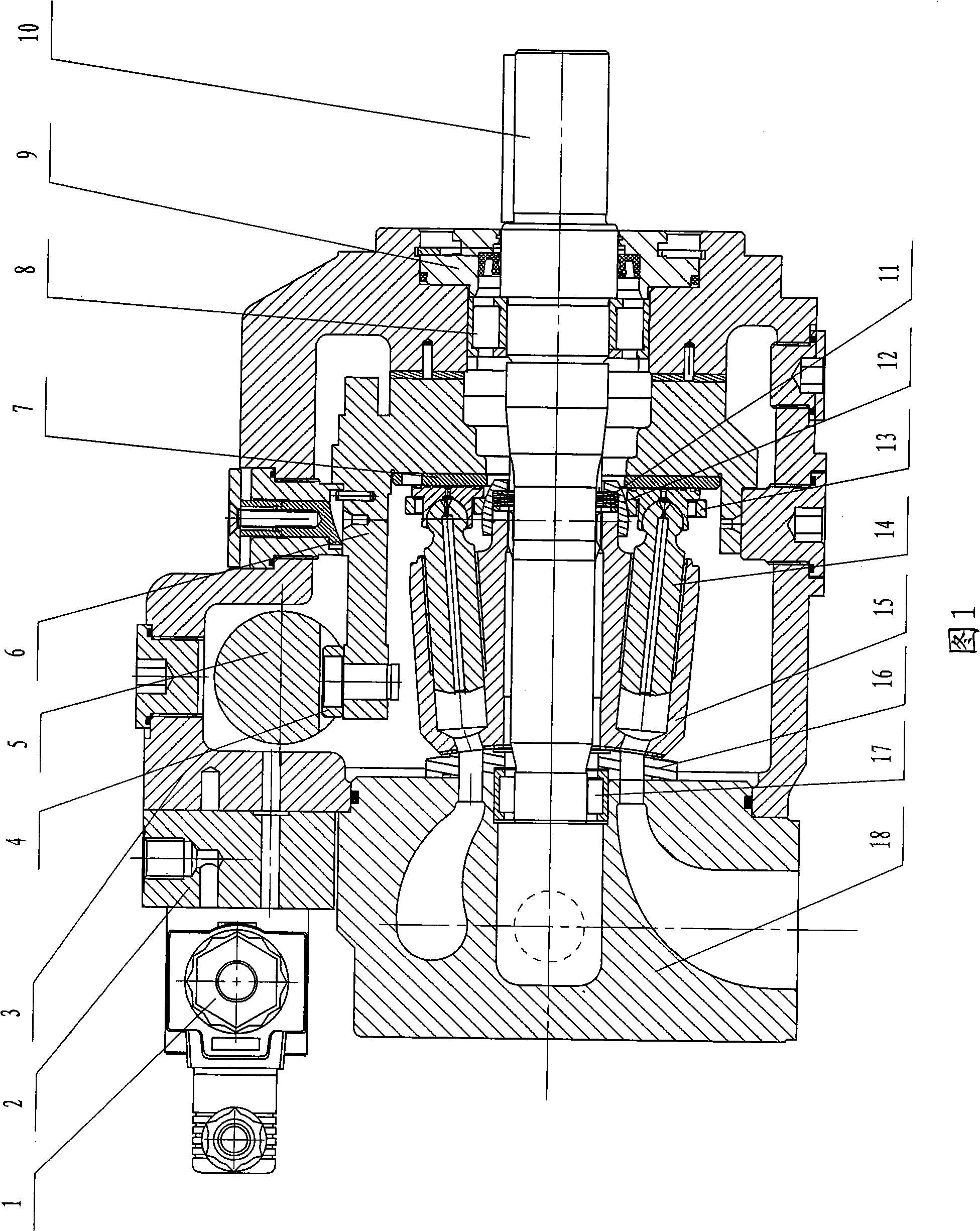

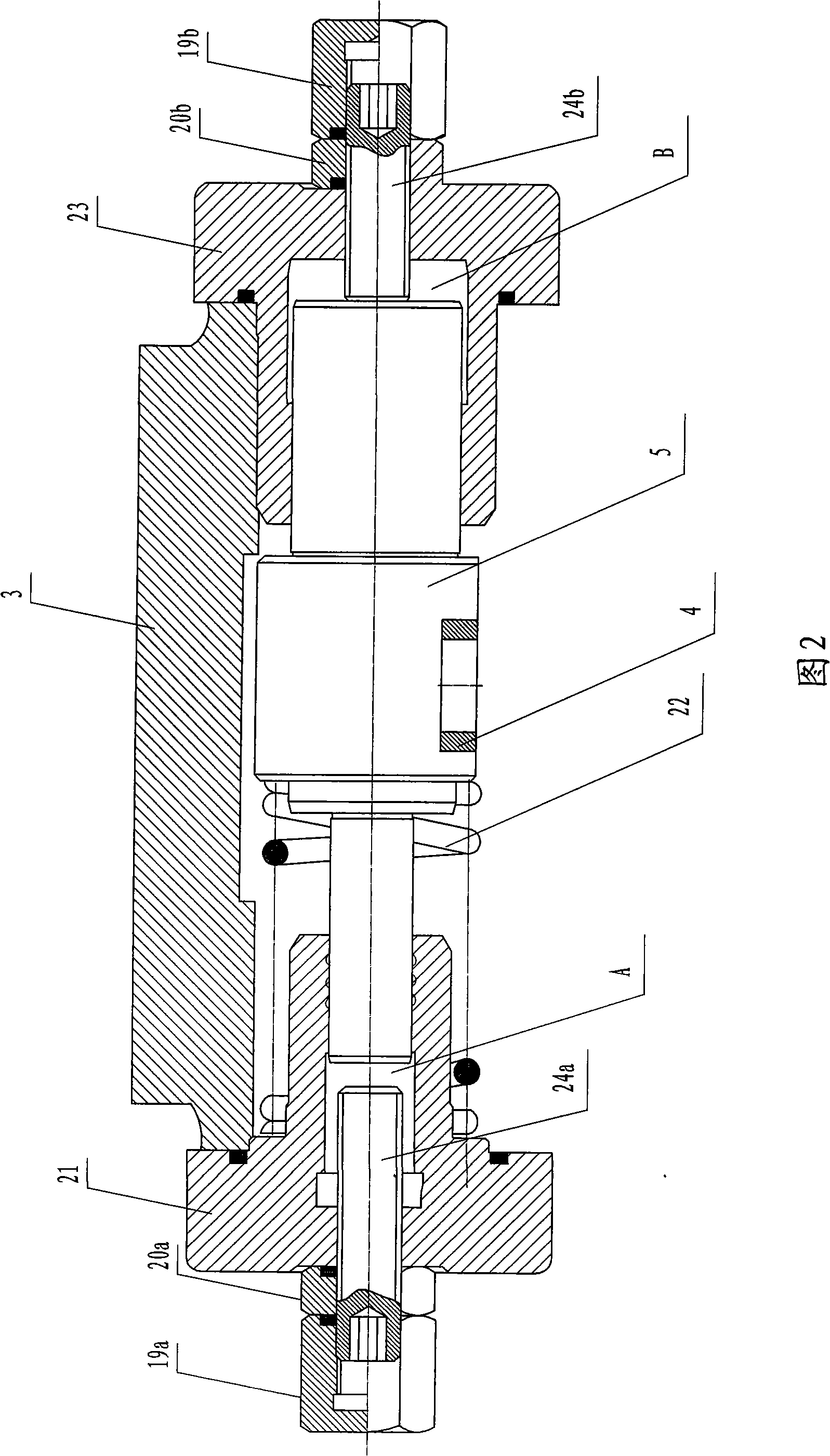

[0027] Embodiment: Referring to Fig. 1 and Fig. 2, the one-way hydraulic variable axial piston pump in this embodiment includes a plunger pump body and a variable displacement mechanism arranged on one side of the plunger pump body.

[0028] The main body of the plunger pump includes a pump body 3, a pump cover 18, a variable plate 6, a return plate 13, a transmission shaft 10, a cylinder assembly 15, a plunger shoe mechanism 14, a slide plate 7, an oil distribution plate 16, and a ball bearing 12 .

[0029] The pump cover 18 is assembled on the pump body 3 to form an airtight space with the pump body 3. The variable plate 6 is arranged in the pump body 3 at an inclined angle with the drive shaft 10. The return disk 13 is arranged on the slide plate 7, and the slide plate 7 is fixed on the variable disk 6,

[0030] The transmission shaft 10 is rotatably installed in the pump body 3 through bearings, specifically through the full-rail end cylindrical roller bearing 17 without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com