Low-noise axial plunger pump based on average pressure

An axial plunger pump and pressure technology, which is applied in the direction of pumps, multi-cylinder pumps, liquid variable displacement machines, etc., can solve the problems of positive and negative overshoot of plunger chamber pressure, pressure shock, cavitation and other problems, and achieve The effect of increasing the effective oil suction and discharging stroke, reducing the rotational torque of the swash plate, and increasing the average outlet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

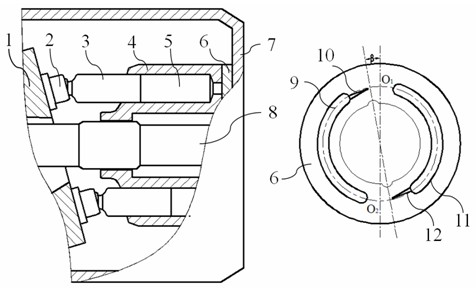

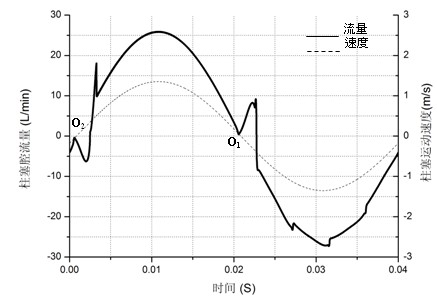

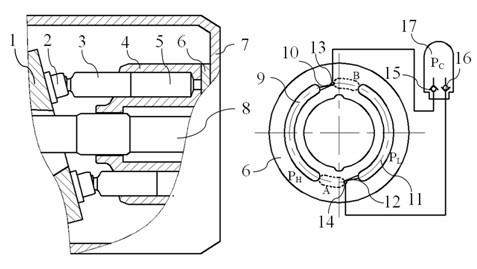

[0015] The plunger chamber moves for one week, and there are two flow backflows, figure 2 It is a typical axial piston pump plunger cavity flow change curve. The upper and lower dead centers at zero speed are the dividing points of oil suction and oil discharge. The flow opposite to the speed is flow backflow. Among them, the flow backflow peak value from the high-pressure oil discharge waist groove to the low-pressure plunger cavity determines the peak value of the plunger pump outlet flow pulsation, and also reduces the effective oil discharge capacity of the plunger pump. From the high-pressure plunger cavity to the low-pressure oil suction waist The backflow of the flow of the groove converts the pressure energy into energy dissipation, which is a kind of internal leakage. The flow distribution structure of the present invention directly connects the plunger cavity near the upper and lower dead centers, and the oil liquid flows from the bottom dead center Near the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com