Device for measuring stirring loss caused by high-speed rotating element of axial plunger pump/motor

An axial piston pump and high-speed rotation technology, which is applied in the field of hydraulic components, can solve the problems of difficult testing and other problems, and achieve the effects of low processing and testing costs, simple and reliable structure, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

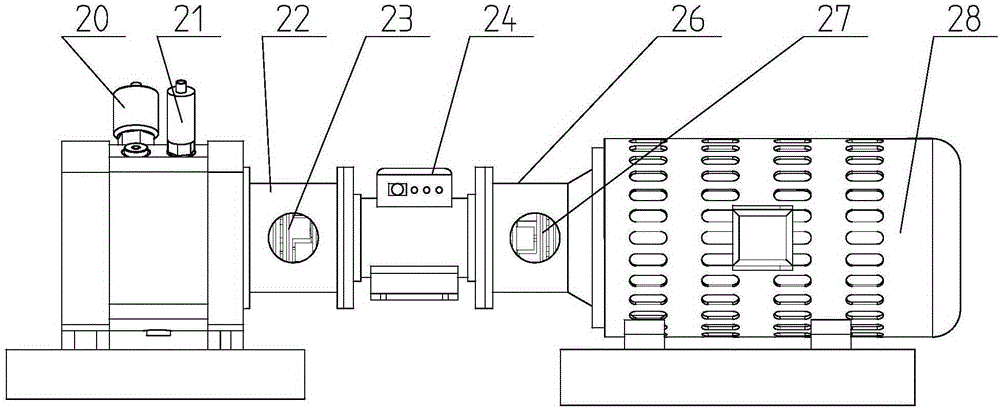

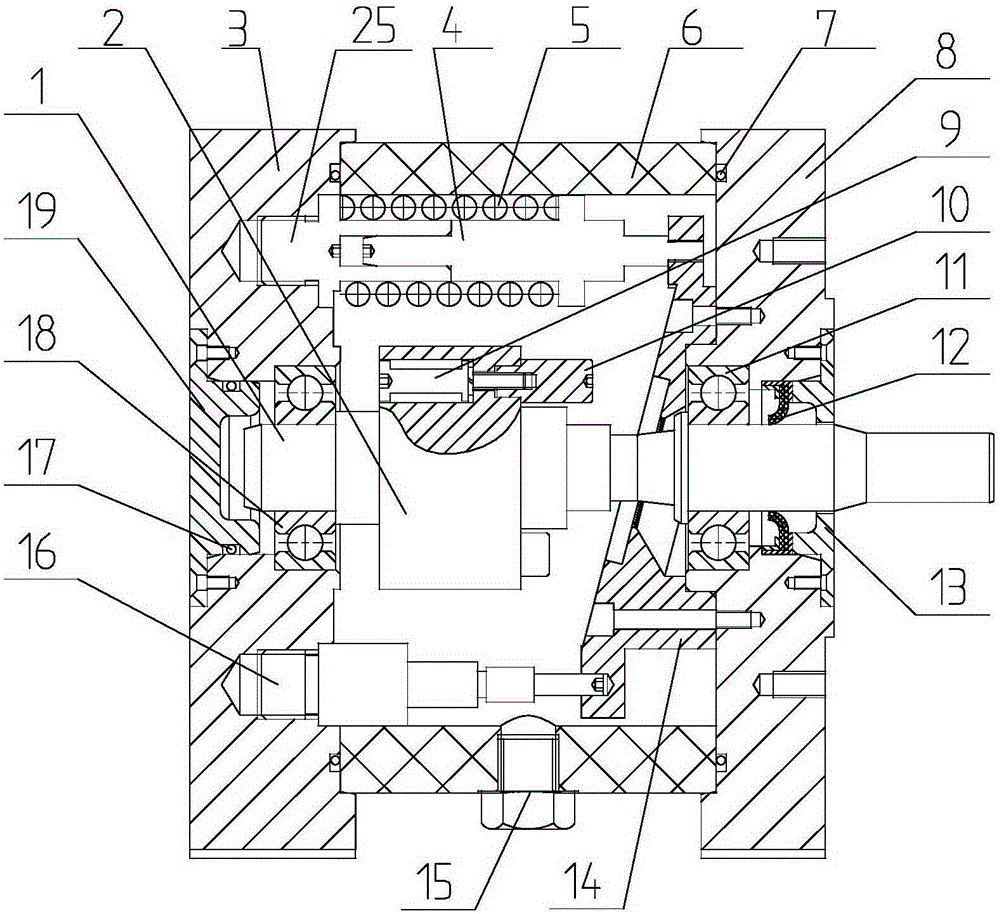

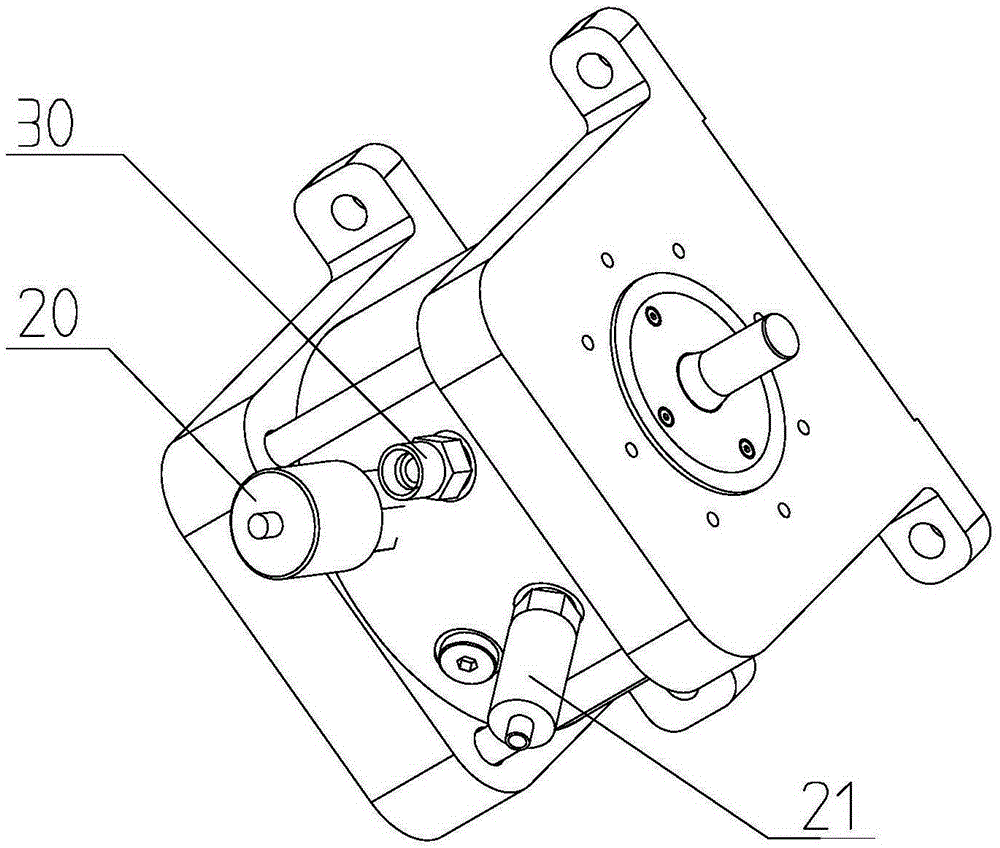

[0020] Such as Figure 1-4 As shown, the present invention includes an analog pump / motor, a first shaft coupling 23, a torque speed sensor 24, a second shaft coupling 27, a variable frequency motor 28, a data acquisition card and an industrial computer; wherein, the analog pump / motor passes through the first The shaft coupling 23 is connected with the torque speed sensor 24; the variable frequency motor 28 is connected with the torque speed sensor 24 through the second shaft coupling 27, and the torque speed sensor 24 is connected with the industrial computer through the data acquisition card; the first shaft coupling 23 is covered with a first Cylindrical support 22, one end of the first cylindrical support 22 is fixedly connected with the front end cover 8, and the other end is fixedly connected with the shell of one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com