Stepless speed varying control method and system for hydraulic on/off machine with high pressure and great flow rate

A hydraulic hoist and continuously variable speed technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as unstable operation process, high energy consumption of the system, and inability to adapt to high pressure and large flow conditions. Achieve high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

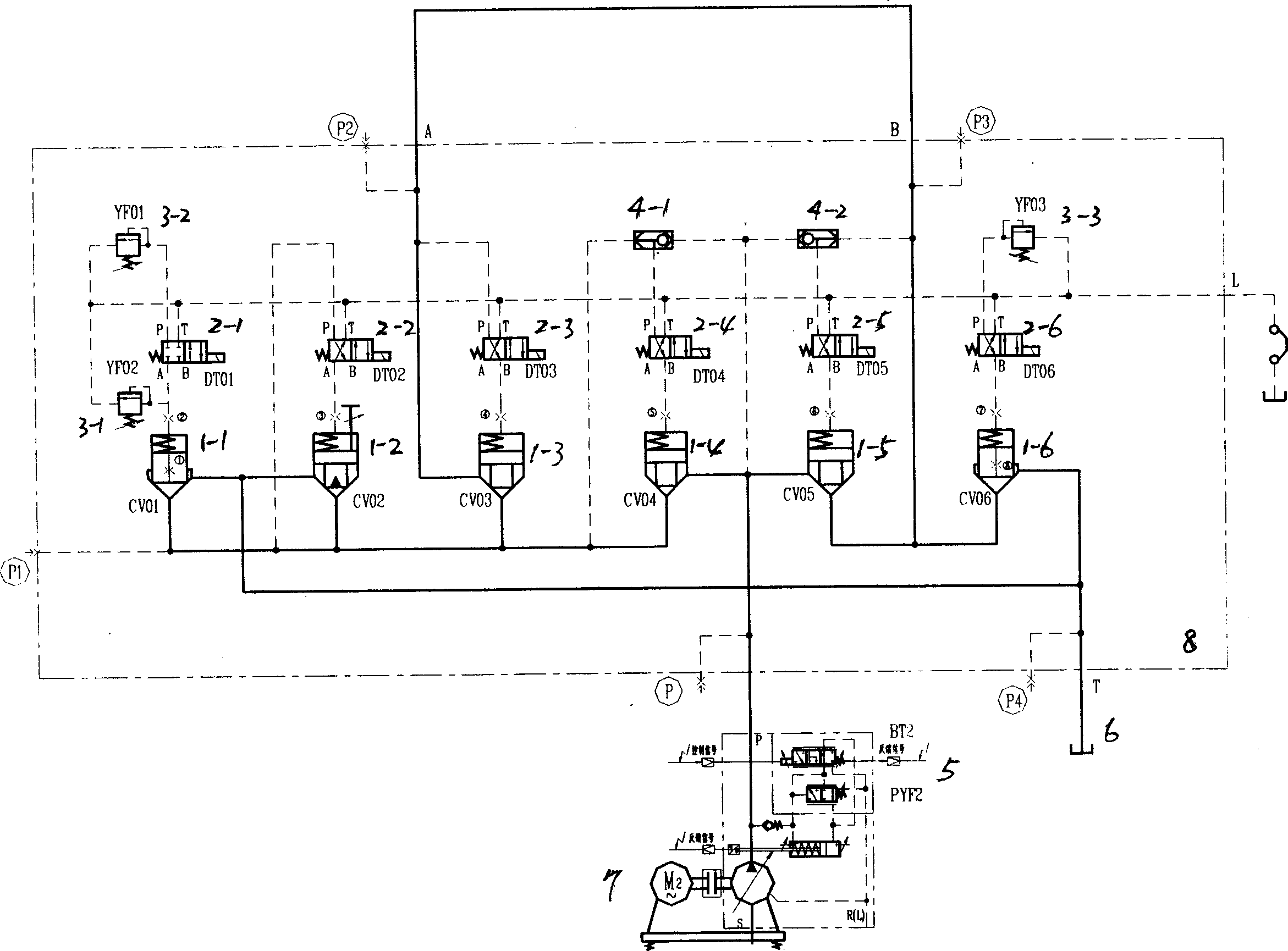

[0029] According to the drawings, P is the pump source interface, T is connected to the oil tank 6, A port is connected to the rod chamber of the oil cylinder, that is, the lower chamber, B is connected to the rodless chamber of the oil cylinder, that is, the upper chamber, and L is the pilot oil drain port.

[0030] The hydraulic control circuit of the water delivery valve hoist is composed of a motor pump unit and a four-way control circuit composed of two-way cartridge valves:

[0031] The motor pump unit is rigidly connected by the motor 7 and the electro-hydraulic proportional variable pump 5 through a coupling and a bell;

[0032] The four-way control circuit is connected by 1-1, 1-2, 1-3, 1-4, 1-5, 1-6 of the two-way cartridge valve assembly through the oil circuit block 8, and each assembly is connected to the electromagnetic switch respectively. Directional valves 2-1, 2-2, 2-3, 2-4, 2-5, 2-6, at the same time, the pressure of the two-way cartridge valve 1-1 is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com