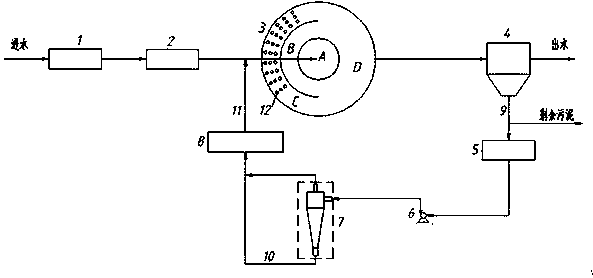

OCO activated sludge improvement process and device for strengthening municipal wastewater treatment

A technology for activated sludge and urban sewage, applied in multi-stage water/sewage treatment, biological water/sewage treatment, special compound water treatment, etc., can solve the toxic and side effects of denitrification system, insufficient denitrification carbon source, and affect the quality of effluent water To achieve the effect of improving sludge settling performance, optimizing effluent water quality, and increasing sludge cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Taking the influent water quality of the secondary treatment system of an urban sewage treatment plant as the research object, the sludge floc concentration is about 3000mg / L, the operating temperature is normal temperature, the influent water quality is COD=355mg / L, BOD 5 =170mg / L, NH 3 -N=38mg / L, TN=48mg / L, TP=15mg / L, SS=80mg / L. After the remaining sludge passes through the bypass ultrasonic-swirl carbon release system, the sludge flocs are broken into small floc structures, and the refractory reticular impurities on the surface of the floc sludge are removed, and the COD of the sludge supernatant Organic matter such as organic matter, polysaccharide and protein concentration increased by 50% to 200%, which greatly supplemented the carbon source concentration and achieved sludge reduction. The measurement results of the Malvern laser particle size analyzer (Beckman Coulter LS 230) show that the particle size distribution of the sludge after cyclone break-up and ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com