Condensate fine treatment high-temperature running system having heat supply and pure condensation modes

A technology of condensate polishing and high-temperature operation, which is applied in the direction of ion exchange water/sewage treatment, etc., and can solve problems such as expensive operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

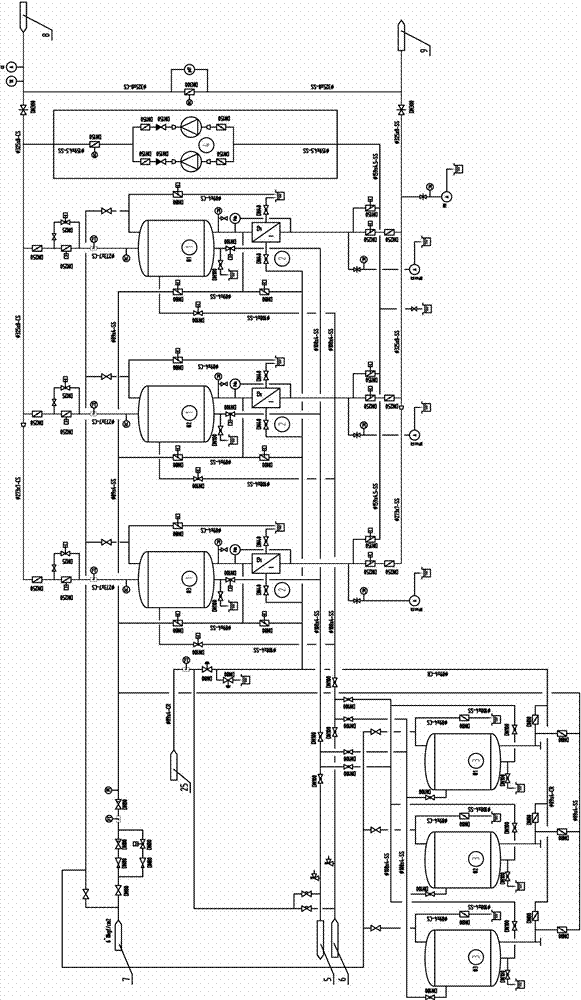

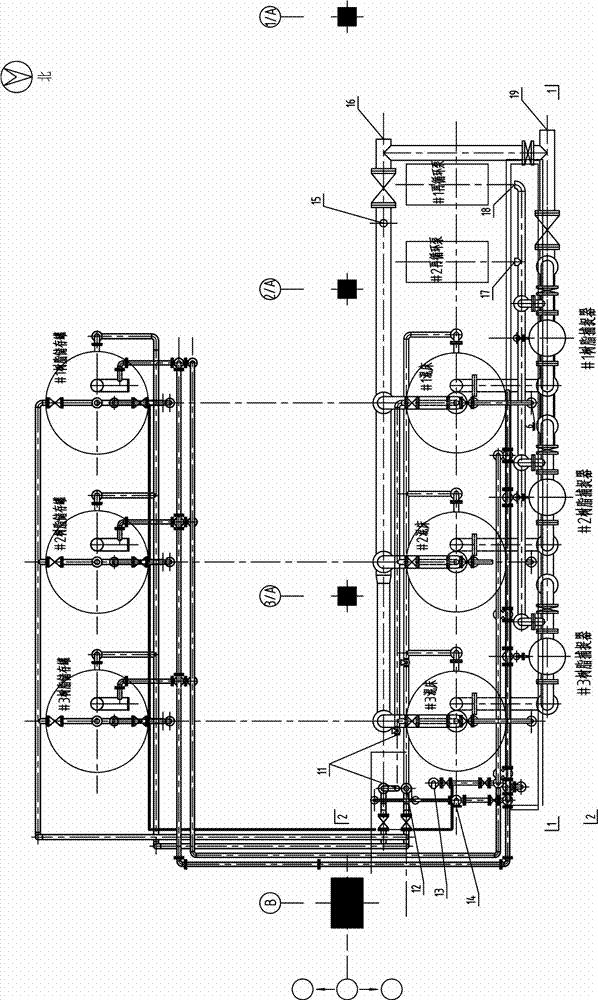

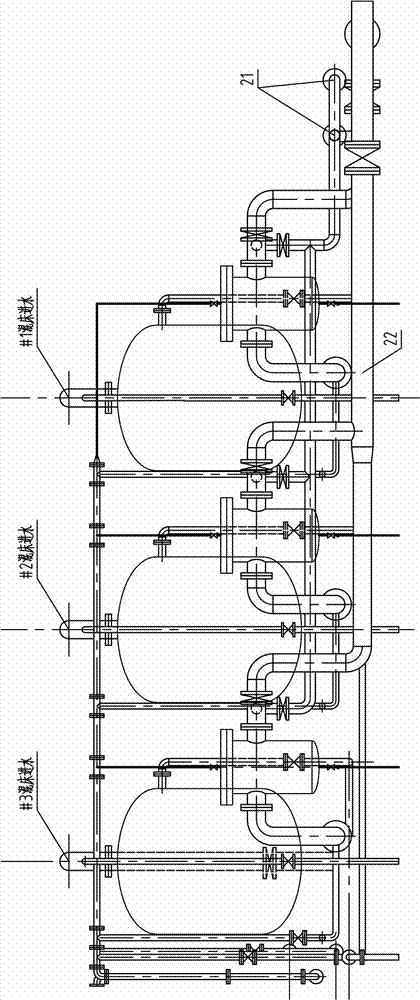

[0038] In order to better understand the high-temperature operation system of condensate polishing with dual modes of heating and pure condensation according to the present invention, the high-temperature operation of condensate polishing with dual modes of heating and pure condensation according to the present invention will be described below with reference to the accompanying drawings Specific embodiments of the system.

[0039]In the improvement of the fine treatment section of the present invention, three new high-speed mixed beds lined with butyl rubber (temperature resistance 100-120°C) are added on the basis of existing equipment, and they are arranged in the original three high-speed mixed beds of No. 2 unit. The location of the bed; the original three high-speed mixed beds lined with natural rubber were changed to resin storage tanks, and they were arranged at the zero-meter expansion end of the No. 2 unit room, and moved to the south of the original high-speed mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com