Multi-physics field-assisted electric resistance welding method for dissimilar metal material

A dissimilar metal, multi-physics technology, applied in resistance welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as increasing the internal dislocation of grains, and achieve the requirements of saving energy, improving mechanical properties, and reducing cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

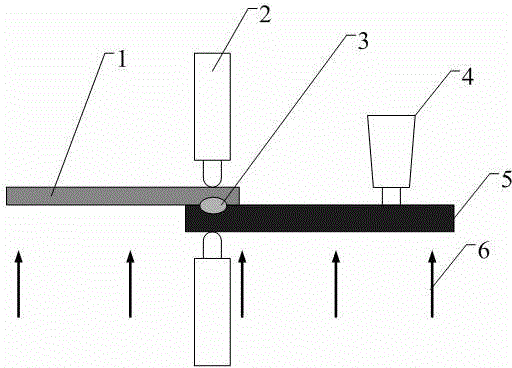

[0028] A welding method for multi-physics-assisted resistance spot welding of dissimilar metals, the steps are as follows:

[0029] 1) Pretreat the surface of the aluminum plate and iron plate, first clean the oil stain on the metal surface with acetone solution, and then use pickling method to remove the oxide film on the surface, the pickling solution is 10wt%HF, 20wt%HNO 3 and 70 wt % water, when the pickling metal is silver-white, it can be finished. After the pickling is finished, rinse it with water quickly, and finally wipe it with alcohol to dry;

[0030] 2) Fix the parts to be welded, apply a magnetic field-ultrasonic composite physical field in the atmospheric environment, and carry out surface treatment on the surface of the welded parts. The treatment time is 1min. The model of the ultrasonic transmitter is YPR55, the ultrasonic frequency is 20KHz, and the tool head outputs The amplitude is 20μm, the output power of the ultrasonic power supply is 2kW, the working p...

Embodiment 2

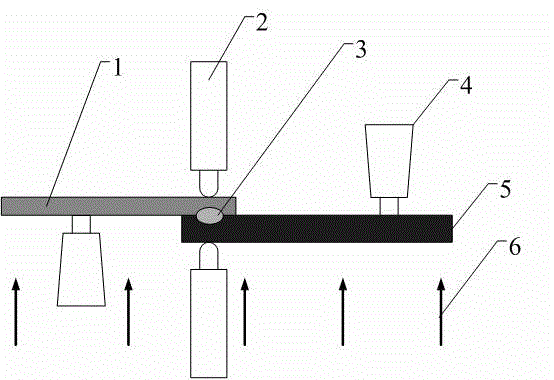

[0035] A multi-physics field-assisted welding method for resistance butt welding of dissimilar metals. The steps are basically the same as those in Embodiment 1, except that an ultrasonic emitting device is added on the surface of the aluminum plate 1, such as figure 2 shown.

Embodiment 3

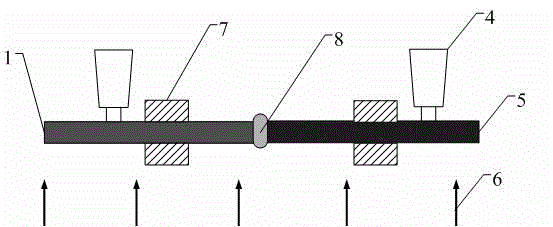

[0037] A welding method for multi-physics-assisted resistance butt welding of dissimilar metals, the steps of which are basically the same as in Embodiment 2, the difference is that resistance butt welding is to assemble the weldment into a butt joint, make its end faces closely contact, and use resistance heat to heat To the plastic state, then cut off the power and quickly apply extrusion force to the two metal plates to complete the welding. When implementing butt welding, two ultrasonic emitting devices 4 are required, which are respectively placed on the outside of the butt welding torch 7, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com