A kind of ferrite material with high stacking and high magnetic permeability and preparation method thereof

A ferrite material, high permeability technology, applied in the field of ferrite synthesis, can solve the problems of low saturation magnetic flux density, impedance matching error, harmonic distortion failure, etc., achieve high permeability, improve permeability rate, the effect of increasing the saturation magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

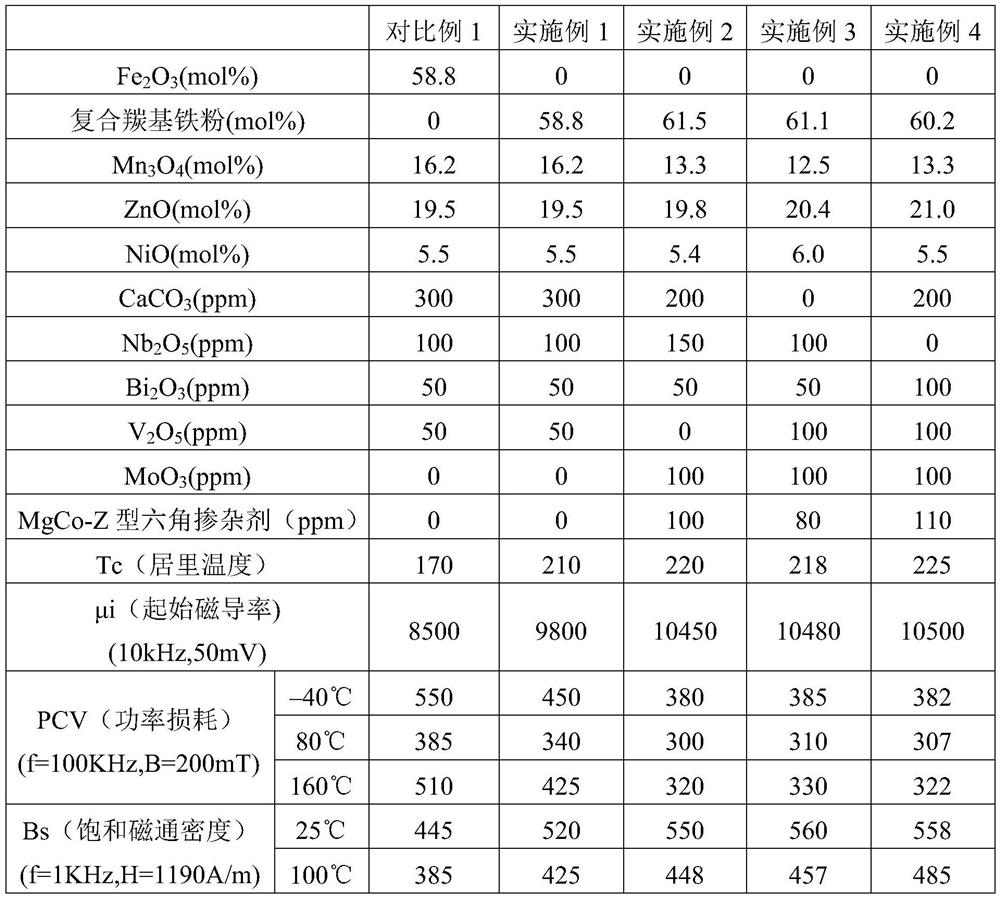

[0036] A high-stack, high-permeability ferrite material and a preparation method thereof, comprising the following steps:

[0037] (1) Take a certain mass ratio of 58.8mol% composite carbonyl iron powder, 16.2mol% Mn 3 o 4 , 19.5mol% ZnO, 5.5mol% NiO mixture, add zirconium balls and liquid forming material: after the ball: liquid ratio is 1:1.2:3.5 ball milling medium, put it into the ball mill pot for mixing and ball milling to form powder, ball milling time 110min, the average particle size of the slurry is 1.8μm;

[0038] (2) Use the natural gas rotary kiln to pre-fire the powder obtained in step (1) at 960°C under air conditions for 4 hours, the feed rate is 2-3kg / h, and the rotation speed is 2N / min to obtain the spinel synthesis degree 10-20% ferrite powder;

[0039] (3) Mix the ferrite powder obtained in step (2) with 300ppm CaCO 3 , 100ppmNb 2 o 5 、50ppm Bi 2 o 3 , 50ppmV 2 o 5 Mix and put the mixed material into the ball mill tank for secondary ball milling, ...

Embodiment 3

[0043] A high-stack, high-permeability ferrite material and a preparation method thereof, comprising the following steps:

[0044] (1) Take a certain mass ratio of 61.5mol% composite carbonyl iron powder, 13.3mol% Mn 3 o 4 , 19.8mol% ZnO, 5.4mol% NiO mixture, add zirconium balls and liquid forming material: after the ball: liquid ratio is 1:1.2:3.5 ball milling medium, put it into the ball mill tank for mixing ball milling to form powder, ball milling time 110min, the average particle size of the slurry is 1.8μm;

[0045] (2) Use the natural gas rotary kiln to pre-fire the powder obtained in step (1) at 960°C under air conditions for 4 hours, the feed rate is 2-3kg / h, and the rotation speed is 2N / min to obtain the spinel synthesis degree 10-20% ferrite powder;

[0046] (3) Mix the ferrite powder obtained in step (2) with 200ppm CaCO 3 , 150ppmNb 2 o 5 、50ppm Bi 2 o 3 , 100MoO 3 , 100ppm MgCo-Z type hexagonal dopant, and put the mixed material into the ball mill tank f...

Embodiment 4

[0050] A high-stack, high-permeability ferrite material and a preparation method thereof, comprising the following steps:

[0051] (1) Take a certain mass ratio of 61.1mol% composite carbonyl iron powder, 12.5mol% Mn 3 o 4 , 20.4mol% ZnO, 6.0mol% NiO mixture, add zirconium balls and liquid forming material: after the ball: liquid ratio is 1:1.2:3.5 ball milling medium, put it into the ball mill tank for mixing ball milling to form powder, ball milling time 110min, the average particle size of the slurry is 1.8μm;

[0052] (2) Use the natural gas rotary kiln to pre-fire the powder obtained in step (1) at 960°C under air conditions for 4 hours, the feed rate is 2-3kg / h, and the rotation speed is 2N / min to obtain the spinel synthesis degree 10-20% ferrite powder;

[0053] (3) ferrite powder obtained in step (2) and 100ppmNb 2 o 5 、50ppm Bi 2 o 3 , 100ppmV 2 o 5 , 100MoO 3 , 80ppm MgCo-Z type hexagonal dopant, and put the mixed material into the ball mill tank for second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com