Method for preventing copper diffusion

A copper interconnection and range technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unstable metal atoms, time-related dielectric breakdown effect is not obvious, etc., to achieve finer size and improve time Related dielectric breakdown, improving the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

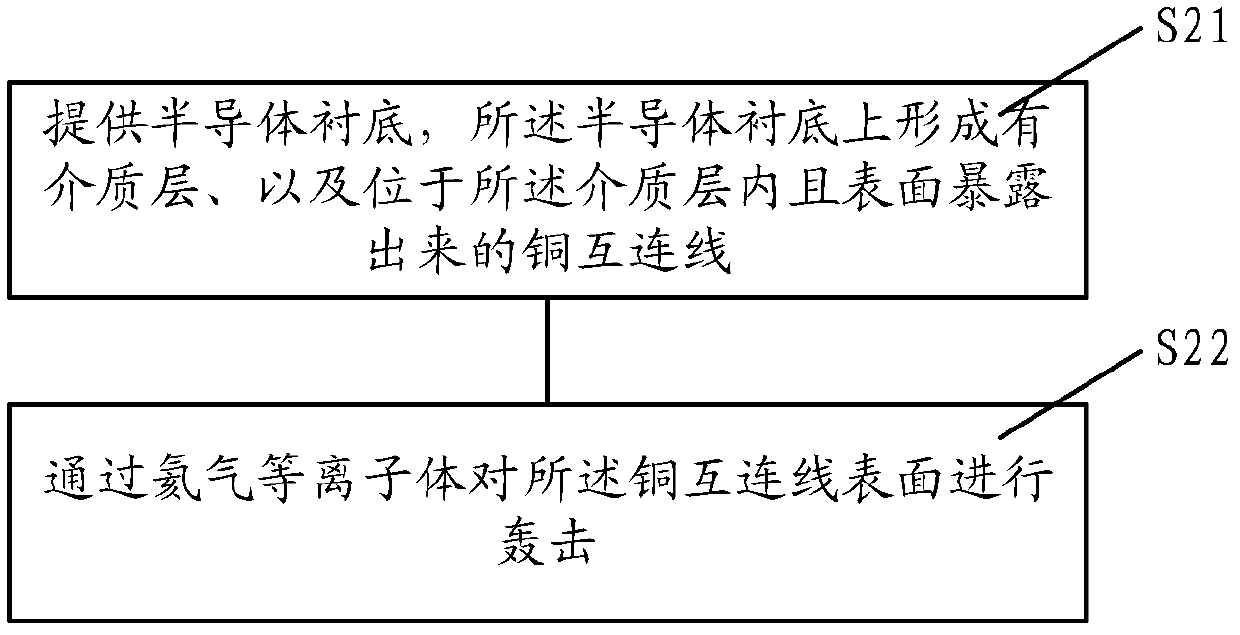

[0033] refer to figure 1 , is a schematic flowchart of a method for preventing copper diffusion in Embodiment 1 of the present invention, and the method includes the following steps:

[0034] Step S21, providing a semiconductor substrate, on which a dielectric layer and copper interconnect lines located in the dielectric layer and exposed on the surface are formed;

[0035] Step S22, bombarding the surface of the copper interconnection wire with helium plasma;

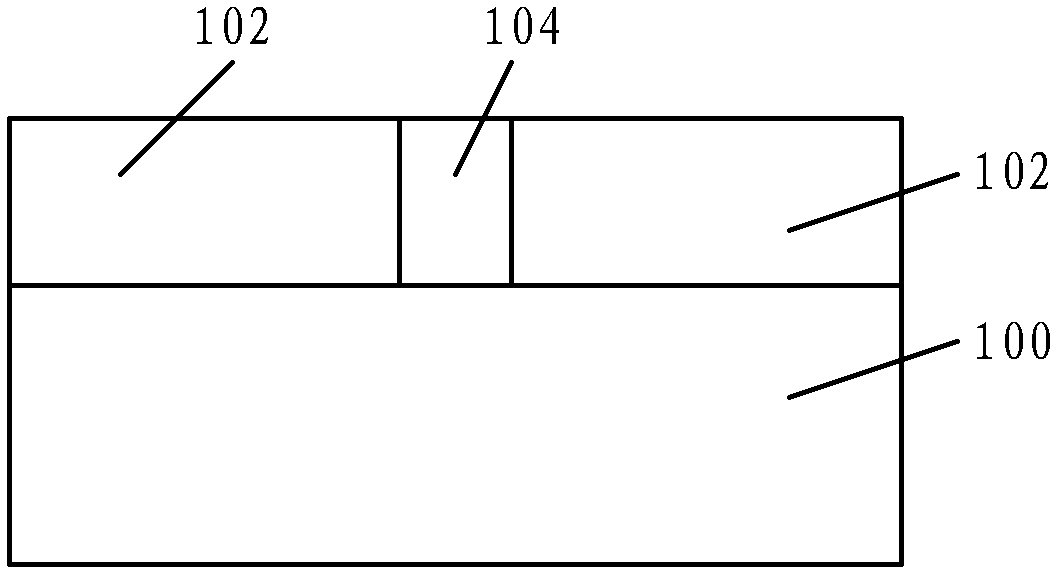

[0036] refer to figure 2 , is a schematic cross-sectional structure diagram of the copper interconnect structure processed by the method for preventing copper diffusion in the first embodiment of the present invention. Incorporate references figure 1 and figure 2 The method for preventing copper diffusion in Example 1 will be described.

[0037] First, step S21 is performed to provide a semiconductor substrate 100 on which a dielectric layer 102 and copper interconnect lines 104 located in the dielectric layer 1...

no. 2 example

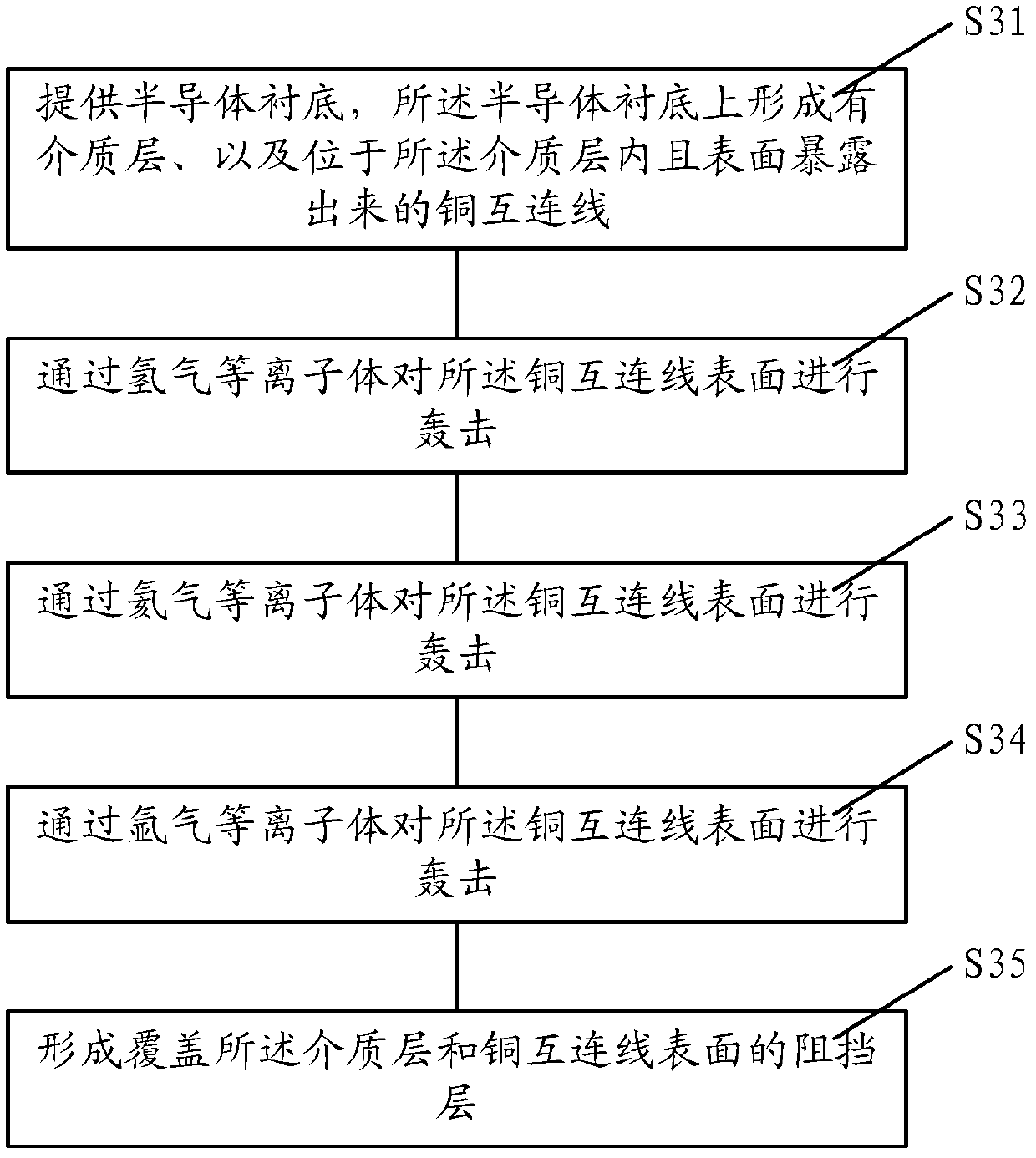

[0045] refer to image 3 , is a schematic flowchart of the method for preventing copper diffusion in the second embodiment of the present invention, including the following steps:

[0046] Step S31, providing a semiconductor substrate, on which a dielectric layer and copper interconnects located in the dielectric layer and exposed on the surface are formed;

[0047] Step S32, bombarding the surface of the copper interconnection wire with hydrogen plasma;

[0048] Step S33, bombarding the surface of the copper interconnection wire with helium plasma;

[0049] Step S34, bombarding the surface of the copper interconnection wire with argon plasma;

[0050] Step S35, forming a barrier layer covering the surface of the dielectric layer and the copper interconnection lines.

[0051] refer to Figure 4 and Figure 5 , are a schematic cross-sectional structure diagram of the copper interconnect structure processed by the method for preventing copper diffusion in the second embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com