A method for manufacturing high-strength mirror-surfaced alumina suitable for the integration of mobile phone back shell and middle plate frame

A technology for a mobile phone back case and a manufacturing method, which is applied to the manufacturing field of high-strength mirrorable alumina, can solve the problems of low material utilization rate, difficult complex structure, complicated process, etc., and achieves high production efficiency, high support strength, and surface strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

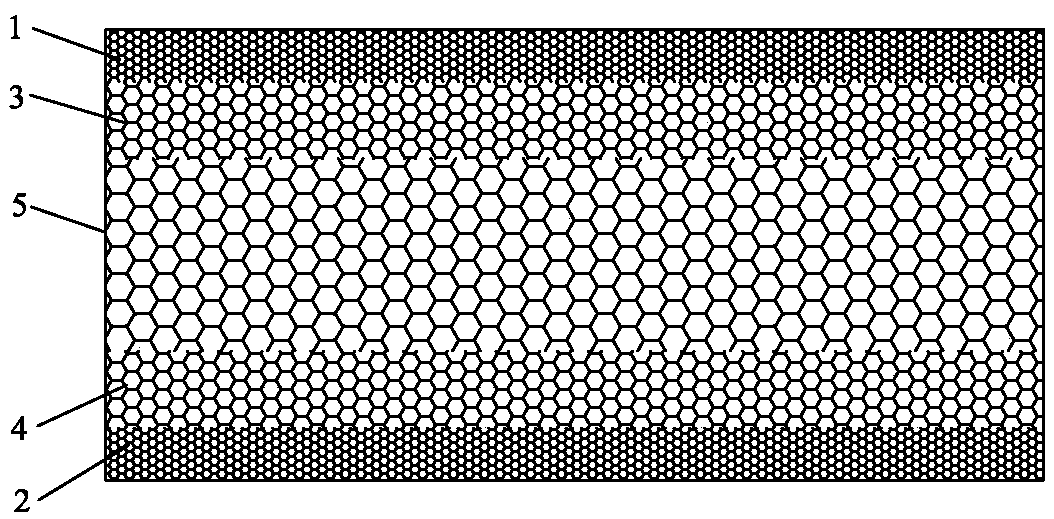

[0033] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a high-strength mirror-surfaced alumina suitable for the integration of the rear shell and the middle plate frame of the mobile phone, and the manufacturing method of this high-strength mirror-surfaced alumina Include the following steps.

[0034] Step 1, preparation of aluminum alloy melt: Weigh high-purity aluminum ingots with an aluminum content of 99.95%, aluminum-iron master alloys, and aluminum-manganese master alloys as raw materials, and then add them to the melting furnace and heat them at 720°C to 750°C Melted into aluminum alloy melt, the mass percentage of each element in the aluminum alloy melt is Si: ≤0.05%, Fe: ≤0.08%, Cu: ≤0.1%, Mn: ≤0.1%, Mg: 2.2-2.8%, Zn : ≤0.05%, Ti: ≤0.05%, single impurity: ≤0.03%, total impurity: ≤0.1%.

[0035] Step 2, casting: cast the aluminum alloy solution according to the process of casting temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com