Preparation method of electrodeposited ni-co/sic nanocomposite coating under a kind of three-electrode system

A three-electrode system and nano-composite technology, applied in coatings, electrolytic coatings, etc., can solve the problems of grain coarsening, inability to maintain stable performance, and weak stability of nanoparticles at high temperature, etc., to achieve fine grain size, The effect of high hardness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

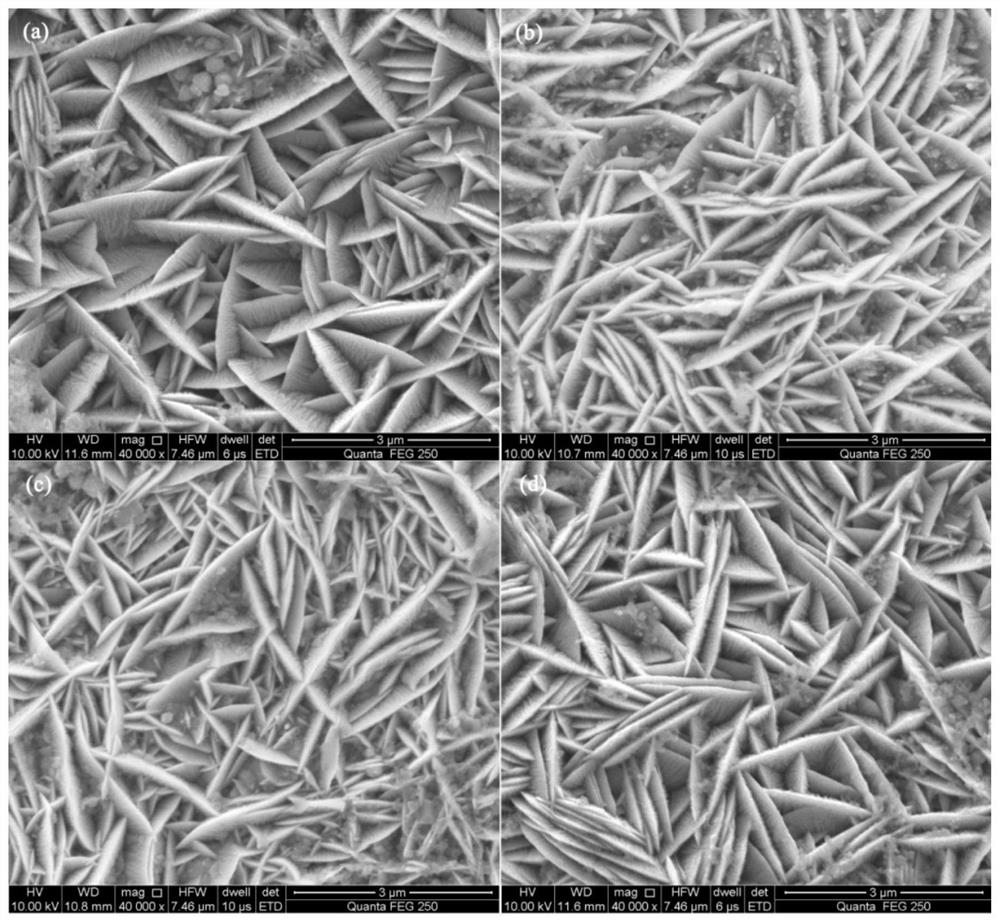

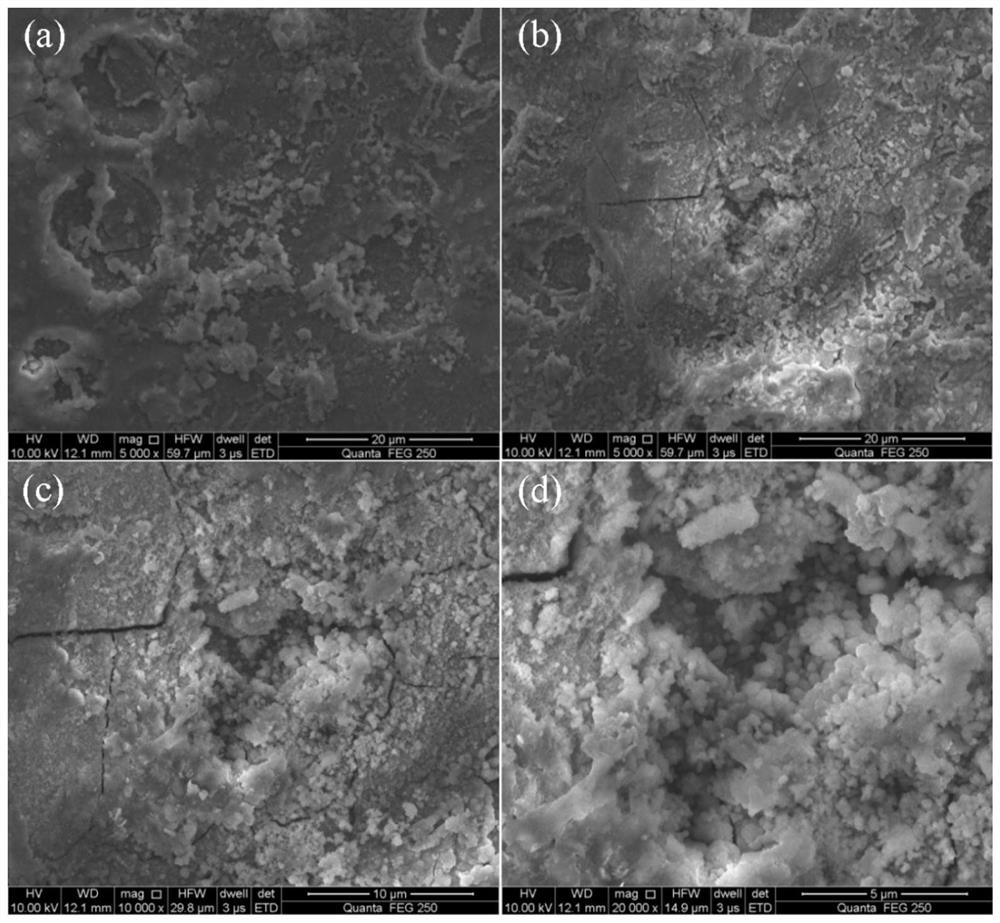

[0044] Example 1 Preparation of electrodeposited Ni-Co / SiC nanocomposite coating under a three-electrode system

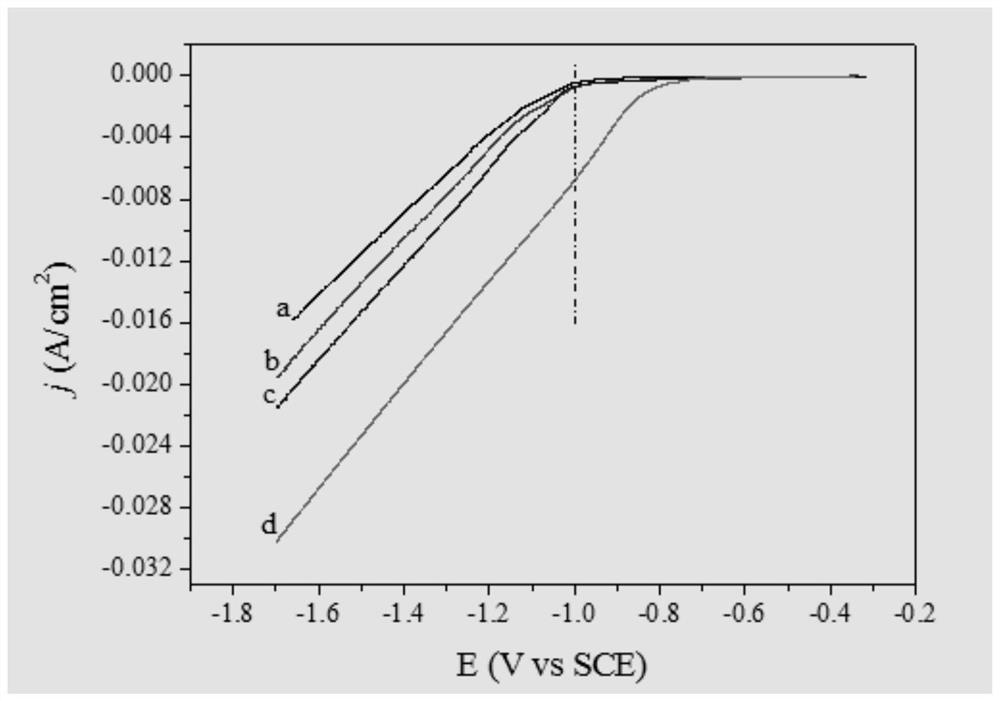

[0045] Preparation of nanoparticle SiC dispersion: using 500mg / L cationic additive cetyltrimethylammonium bromide (critical micelle concentration 9.2×10 -4 mol / L) as a dispersant, add nano-SiC with different concentrations of 0g / L, 5g / L, 10g / L, 15g / L, and 20g / L respectively, and then sonicate until the nanoparticles are completely dispersed into the solution, and then stir for 24h to complete Then add 300 mg / L non-ionic surfactant Triton X-100, and conduct ultrasound again for 3 hours to obtain stable and uniform nanoparticle SiC dispersions with different concentrations;

[0046] Preparation of modified electroplating solution: The electroplating solution was mixed with nanoparticle SiC dispersions of different concentrations to obtain a modified electroplating solution. The composition of the modified electroplating solution is shown in Table 1;

[0047] Prepara...

Embodiment 2

[0054] Example 2 Preparation of electrodeposited Ni-Co / SiC nanocomposite coating under a three-electrode system

[0055] Preparation of nanoparticle SiC dispersion: using 500mg / L cationic additive cetyltrimethylammonium bromide (critical micelle concentration 9.2×10 -4 mol / L) as a dispersant, after adding nano-SiC, ultrasonicate until the nanoparticles are completely dispersed into the solution, then stir for 24h, then add 300mg / L non-ionic surfactant Triton X-100, and then ultrasonicate for 3h To obtain a stable and uniform nanoparticle SiC dispersion;

[0056] Preparation of the modified electroplating solution: the electroplating solution was mixed with the nanoparticle SiC dispersion to obtain the modified electroplating solution. The composition of the modified electroplating solution is shown in Table 2;

[0057] Preparation of Ni-Co / SiC nanocomposite coating: Firstly, two nickel sheets with 99.9% nickel content and cobalt sheets with 99.9% cobalt content are rolled tog...

Embodiment 3

[0064] Example 3 Preparation of electrodeposited Ni-Co / SiC nanocomposite coating under a three-electrode system

[0065] Preparation of nanoparticle SiC dispersion: using 500mg / L cationic additive cetyltrimethylammonium bromide (critical micelle concentration 9.2×10 -4 mol / L) as a dispersant, after adding nano-SiC, ultrasonicate until the nanoparticles are completely dispersed into the solution, then stir for 24h, then add 300mg / L non-ionic surfactant Triton X-100, and then ultrasonicate for 3h To obtain a stable and uniform nanoparticle SiC dispersion;

[0066] Preparation of the modified electroplating solution: the electroplating solution was mixed with the nanoparticle SiC dispersion to obtain the modified electroplating solution. The composition of the modified electroplating solution is shown in Table 3;

[0067]Preparation of Ni-Co / SiC nanocomposite coating: Firstly, two nickel sheets with 99.9% nickel content and cobalt sheets with 99.9% cobalt content are rolled toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com