Feeding mechanism of stamping equipment for motor rotor piece

A stamping equipment and motor rotor technology, applied in the field of stamping equipment, can solve problems such as difficult molds, stamping material jams, inaccurate material distribution, etc., and achieve the effects of simple and convenient maintenance, long service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

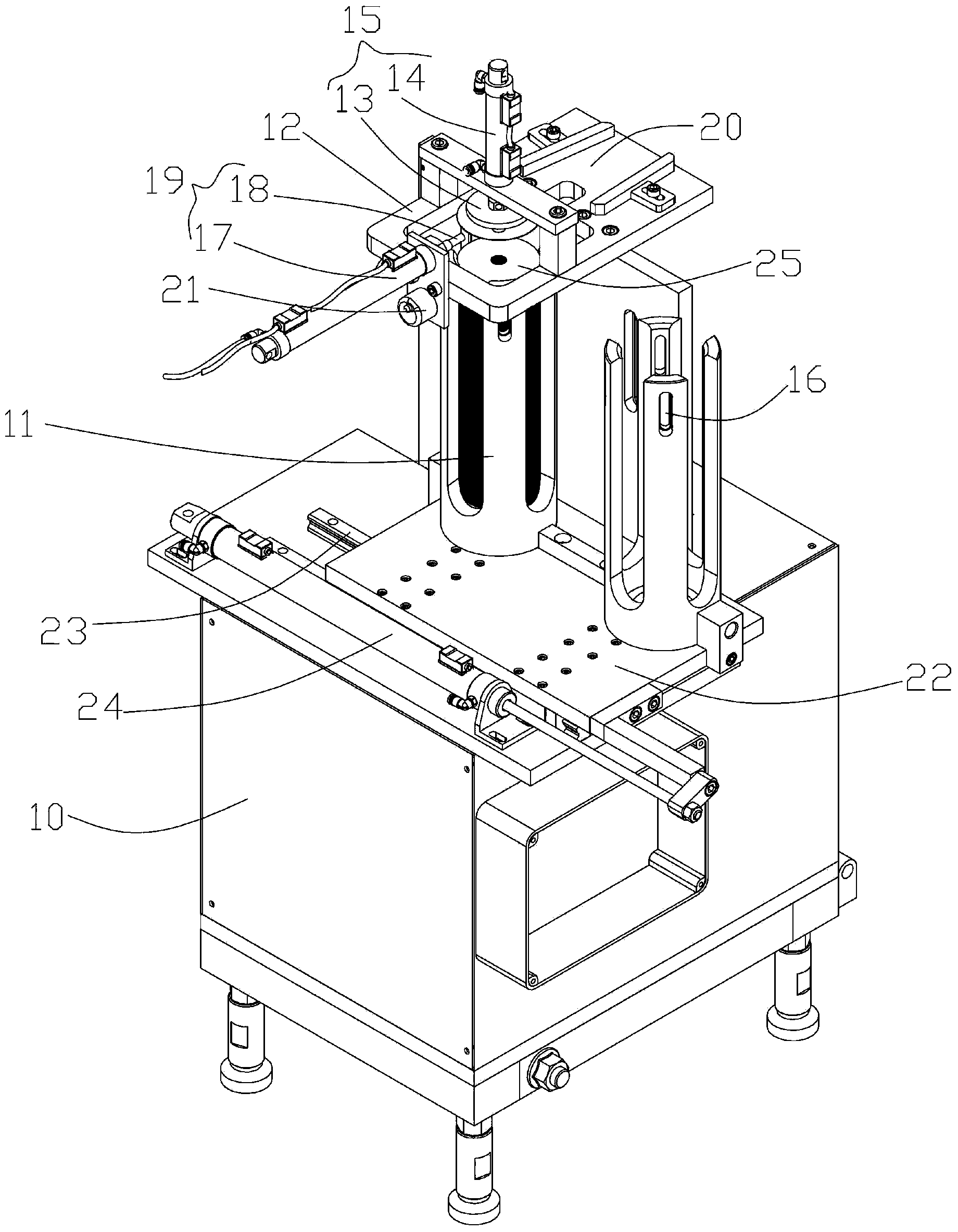

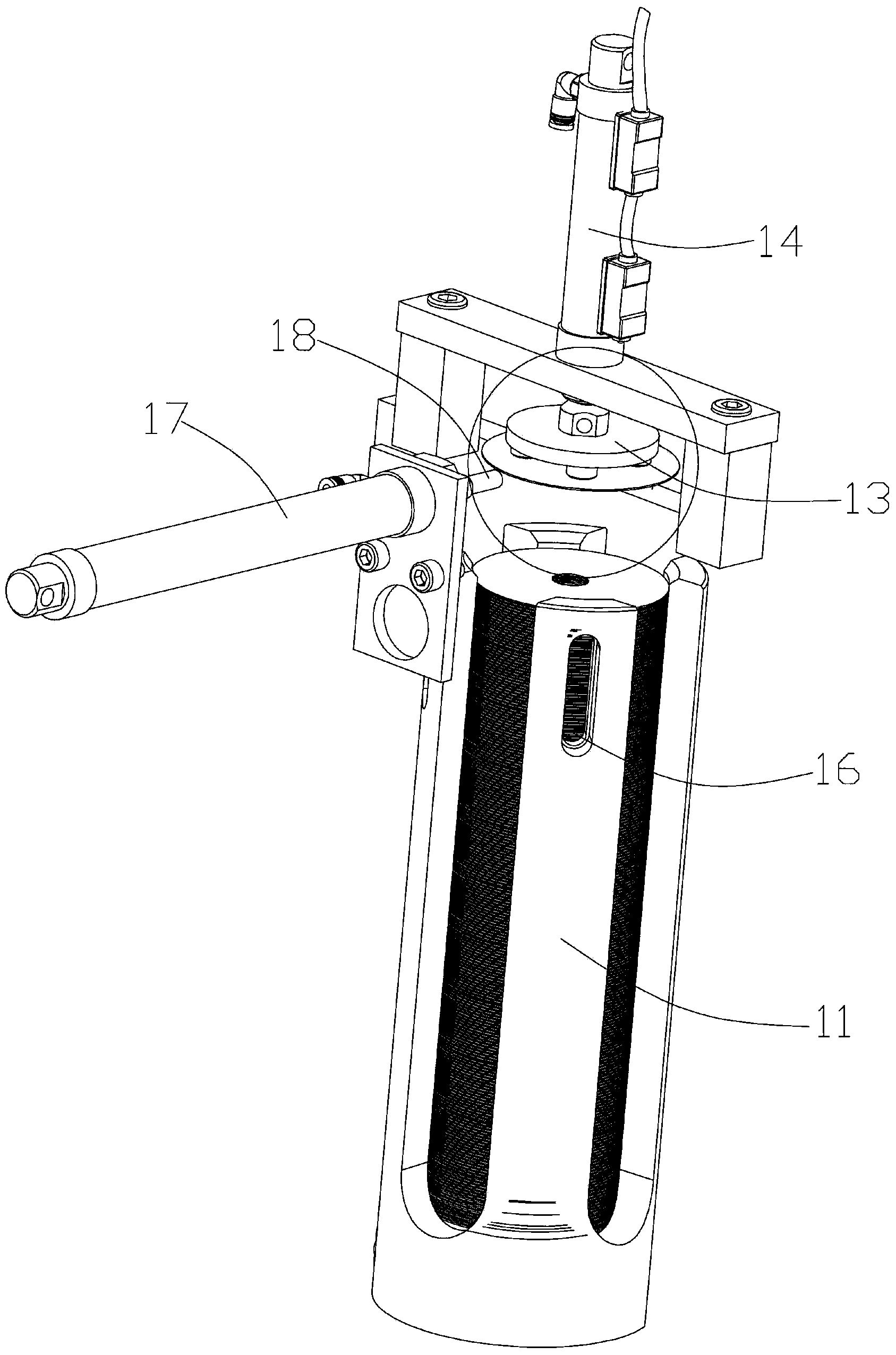

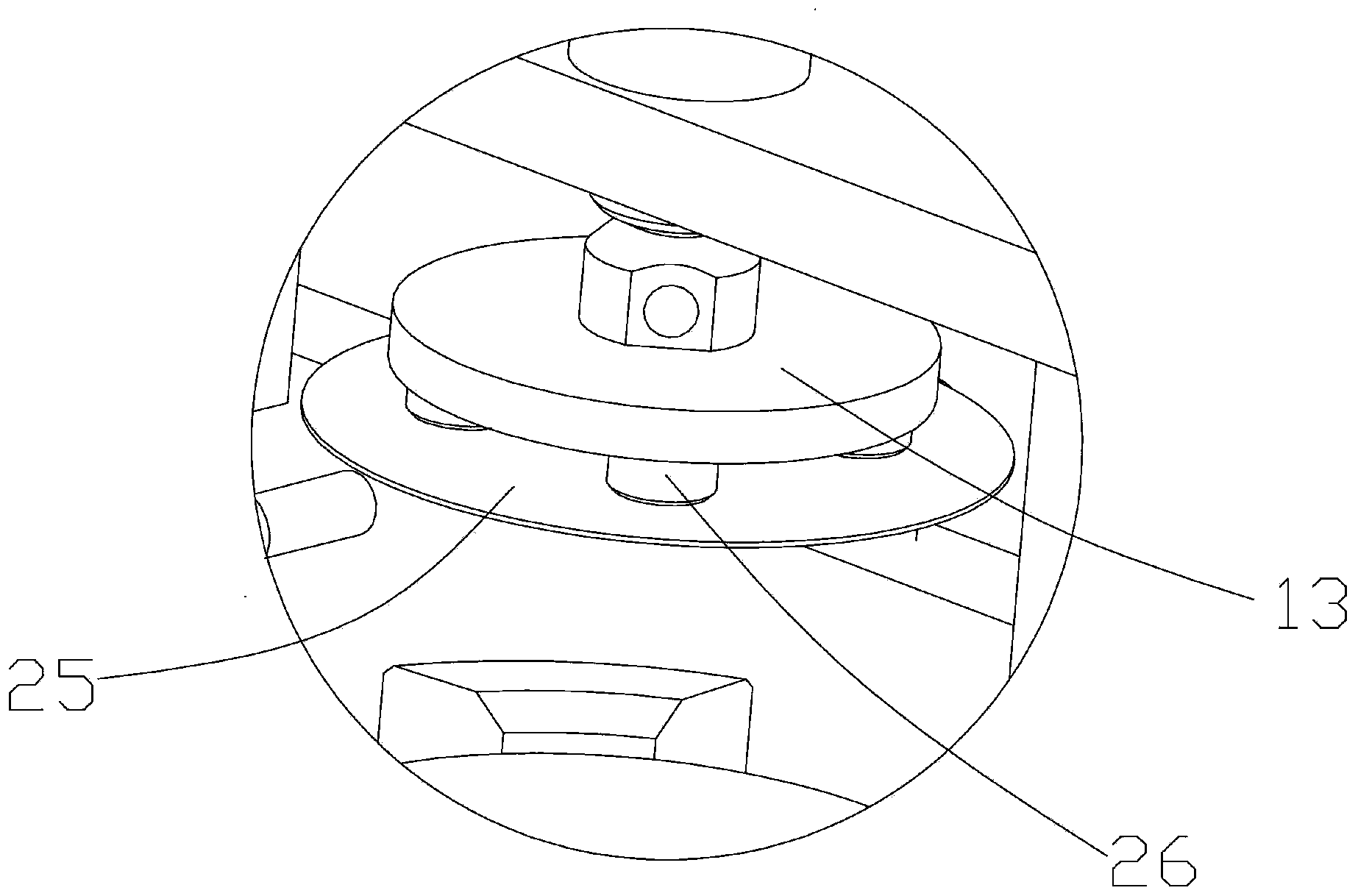

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3: The feeding mechanism of the stamping equipment for the motor rotor sheet, including a frame 10, the frame 10 is provided with a storage barrel 11 and a material distribution device 15, and the material distribution device 15 is arranged on the storage device through a support frame 12 Above the material storage tank 11, a material ejector rod is arranged below the material storage tank 11, and the material ejector rod penetrates from the bottom of the material storage tank 11 to push the blank 25 upward, wherein the material distribution device 15 includes a suction The material tray 13 and the power assembly 14 that drives the reciprocating linear movement of the material suction plate 13, the material suction plate 13 is located directly above the discharge port of the material storage barrel 11, and can quickly, conveniently and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com