Multi-gear pump with step variable system

A variable system and gear pump technology, applied in the direction of pump, pump control, rotary piston type/swing piston type pump combination, etc., can solve the occasions where high power is not suitable, the structure of variable piston pump is complex, and it is resistant to oil pollution. Low capacity and other problems, to achieve the effect of strong resistance to oil pollution, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

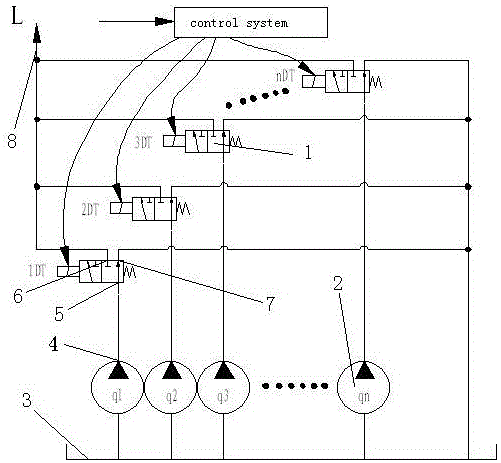

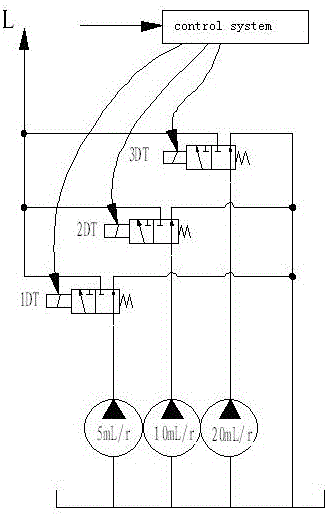

[0015] The present invention includes at least three gear pumps 1 (q1, q2, q3...qn) with different displacements, at least three electromagnetic reversing valves 2 (1DT, 2DT, 3DT...nDT), each gear pump 1 has A separate oil discharge port 4, the oil discharge port 4 of each gear pump 1 is connected to the oil inlet 5 of the electromagnetic reversing valve 2, and the other two oil ports 6 and 7 of the electromagnetic reversing valve 2 are respectively connected to the oil tank 3 and the main drain Oil port 8 communicates. The total oil discharge port 8 communicates with the system L, that is, the oil discharge is sent into the system through the total oil discharge port.

[0016] All the gear pumps of the present invention are coaxially connected and driven by a prime mover. Prime mover refers to power input equipment such as motors and engines.

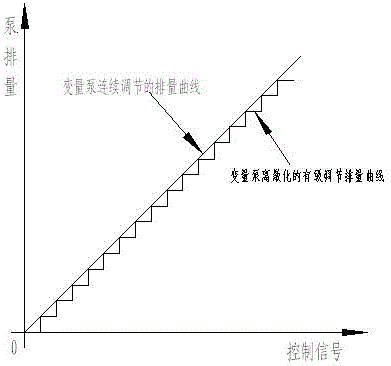

[0017] The displacement of the pumps of the present invention is arranged in a proportional number sequence, how many gear pumps th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com