Isolator for sterility detection process

An isolator and process technology, applied in clean rooms and other directions, can solve problems such as artificial pollution, and achieve the effects of reducing pollution, increasing controllability, reducing operating costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

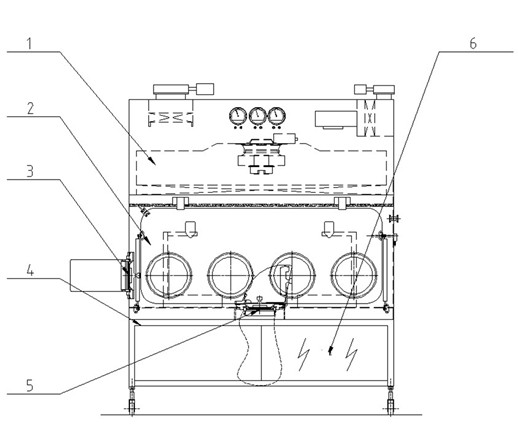

[0022] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0023] Such as figure 1 As shown, a kind of aseptic detection process isolator provided by the present invention comprises a top air treatment system 1, a glove box assembly 2, and an aseptic transfer bin 3 is installed on the isolation wall of the glove box assembly 2 to realize material-free Bacteria transfer, the bottom frame assembly 4 is used to fix and support the glove box assembly 2 and realize the overall movement of the isolator in the aseptic room, the bag out device assembly 5 is installed at the bottom of the glove box assembly 2 to collect For the generated waste, the electrical cabinet assembly 6 installs the electric control part of the entire isolator in the electrical cabinet.

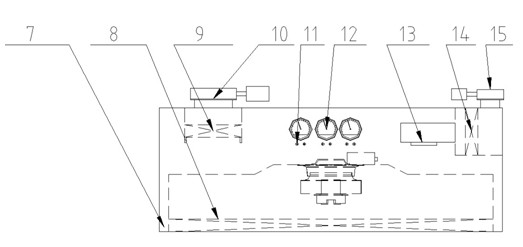

[0024] Such as figure 2 As shown, the air treatment system 1 includes a plenum housing 7, a circulating fan filter unit 8, an H14 fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com