Preparation method of lithium niobate optical waveguide

A technology of lithium niobate and optical waveguide, which is applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of poor resistance to photorefractive damage, small size of optical waveguide, and limitation of conversion efficiency, etc., to reduce waveguide transmission loss , good verticality and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

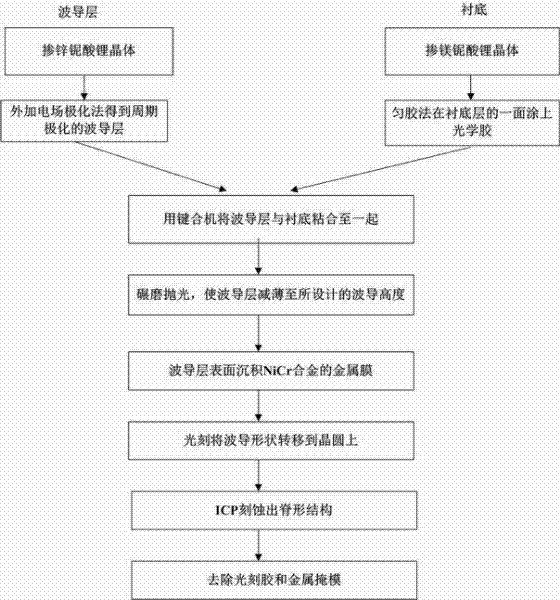

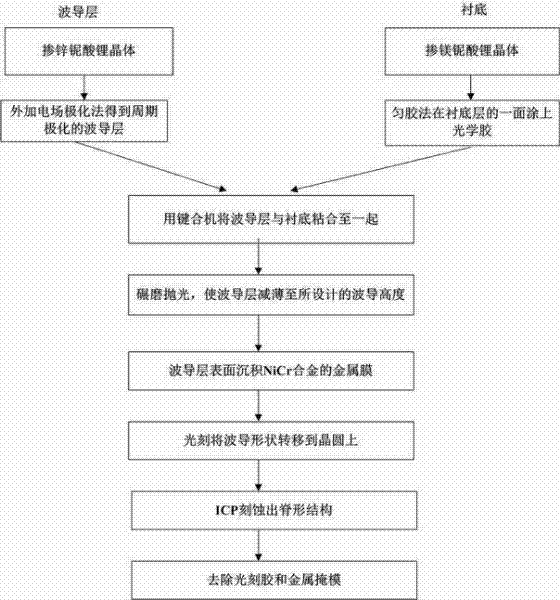

[0025] Embodiment 1 is to prepare a lithium niobate optical waveguide with a ridge waveguide width of 5 μm and a height of 4 μm, such as figure 1 Shown, its preparation method comprises the following steps:

[0026] (1) A zinc-doped z-cut lithium niobate wafer (Zn:LN) is selected as the waveguide layer, and its zinc-doped concentration ranges from 7 to 9 mol%, and 7 mol% is used in this embodiment. The substrate is a magnesium-doped lithium niobate crystal (Mg:LN), and the magnesium-doped concentration ranges from 5 to 9 mol%, and 5 mol% is used in this embodiment.

[0027] (2) Periodically polarize the waveguide layer by using the external electric field polarization method to prepare a periodic domain inversion structure of the waveguide layer; where the polarization period is substituted into the periodic polarization formula Λ by using different wavelengths of refraction indices of zinc-doped lithium niobate 0 =1 / (n p / λ p -n i / λ i -n s / λ s ), where Λ 0 is the po...

Embodiment 2

[0033] Embodiment 2 is to prepare a lithium niobate optical waveguide with a ridge waveguide width of 8 μm and a height of 5 μm, and its preparation method includes the following steps:

[0034] (1) The waveguide layer in the lithium niobate waveguide is selected as magnesium-doped lithium niobate crystal (Mg:LN), the concentration range of magnesium doping is 5-9 mol%, 5 mol% is taken in this embodiment, and the substrate is lithium tantalate crystal (LT).

[0035] (2) Periodically polarize the waveguide layer by using an external electric field polarization method to prepare a periodic domain inversion structure of the waveguide layer; where the polarization period is substituted into the periodic polarization formula Λ by using different wavelengths of magnesium-doped lithium niobate 0 =1 / (n p / λ p -ni / λ i -n s / λ s ), where Λ 0 is the polarization period, let the pump light wavelength λ p =775nm, signal light wavelength λ s =1545nm, idler wavelength λ i =1555nm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com