Isolator for sterile weighing and burdening process

A batching process and isolator technology, applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve problems such as artificial pollution, achieve the effects of reducing pollution, increasing controllability, and reducing clean production areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

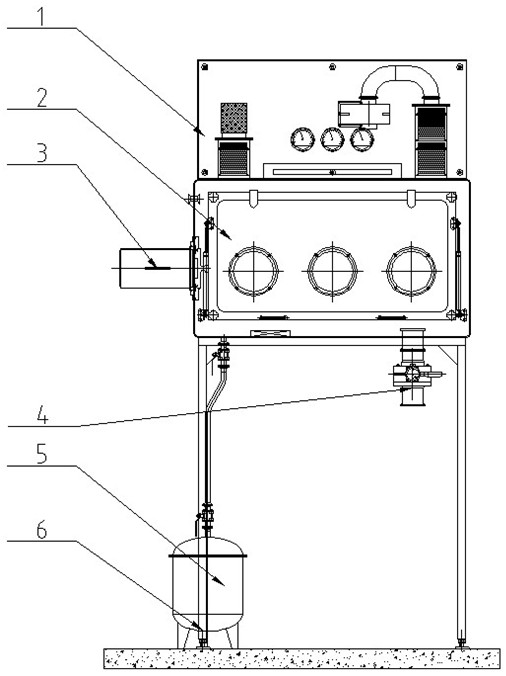

[0023] Such as figure 1 As shown, an aseptic weighing and batching process isolator provided by the present invention includes a top air treatment system 1, a glove box assembly 2, and an aseptic transfer interface 3 is installed on the isolation wall of the glove box assembly 2 to realize Aseptic transfer of materials, aseptic docking valve assembly 4 is installed at the bottom of the glove box assembly 2 to realize the aseptic docking of the batching container, and the drainage system 5 is installed at the bottom of the glove box assembly 2 to collect the waste liquid of the isolator CIP , the bottom frame assembly 6 is used to support all upper isolator assemblies.

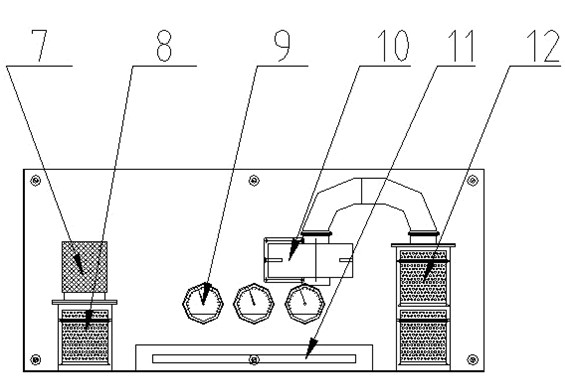

[0024] Such as Figure 2A and Figure 2B As shown, the air treatment system 1 includes a box body 14, the exhaust fan 10 is arranged on the box body 14, the exhaust fan 10 pipeline is connected to the exhaust filter 12, and the box body 14 is provided with a connected pre-filter 7 and The air inlet filter 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com