Vertical continuous casting production device and method for round billets of extra large specification

A technology of super-large size and production equipment, applied in the field of iron and steel smelting, can solve problems such as being unsuitable for the production of super-large size round billets, and achieve the effects of improving productivity and yield, expanding product range, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

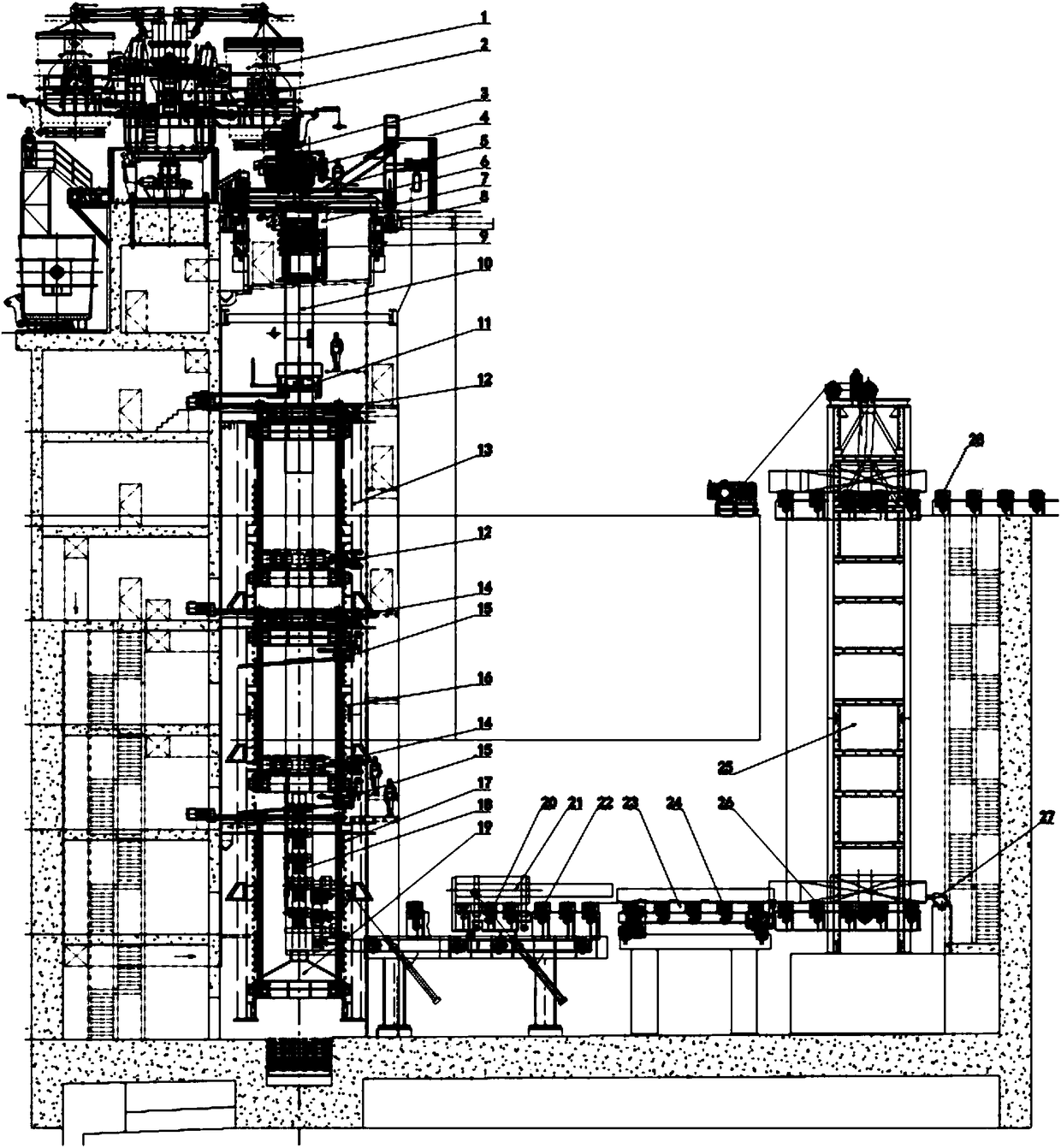

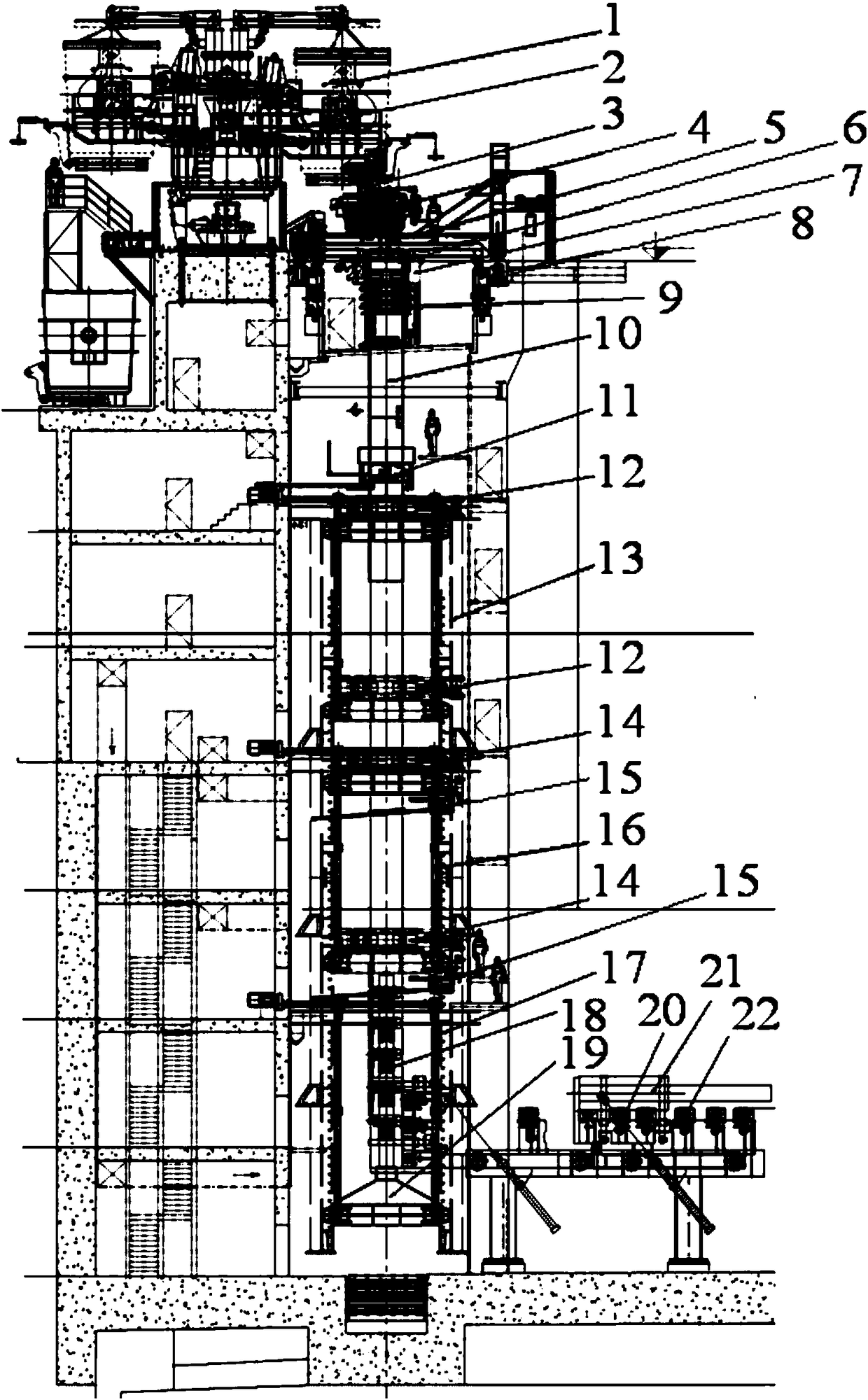

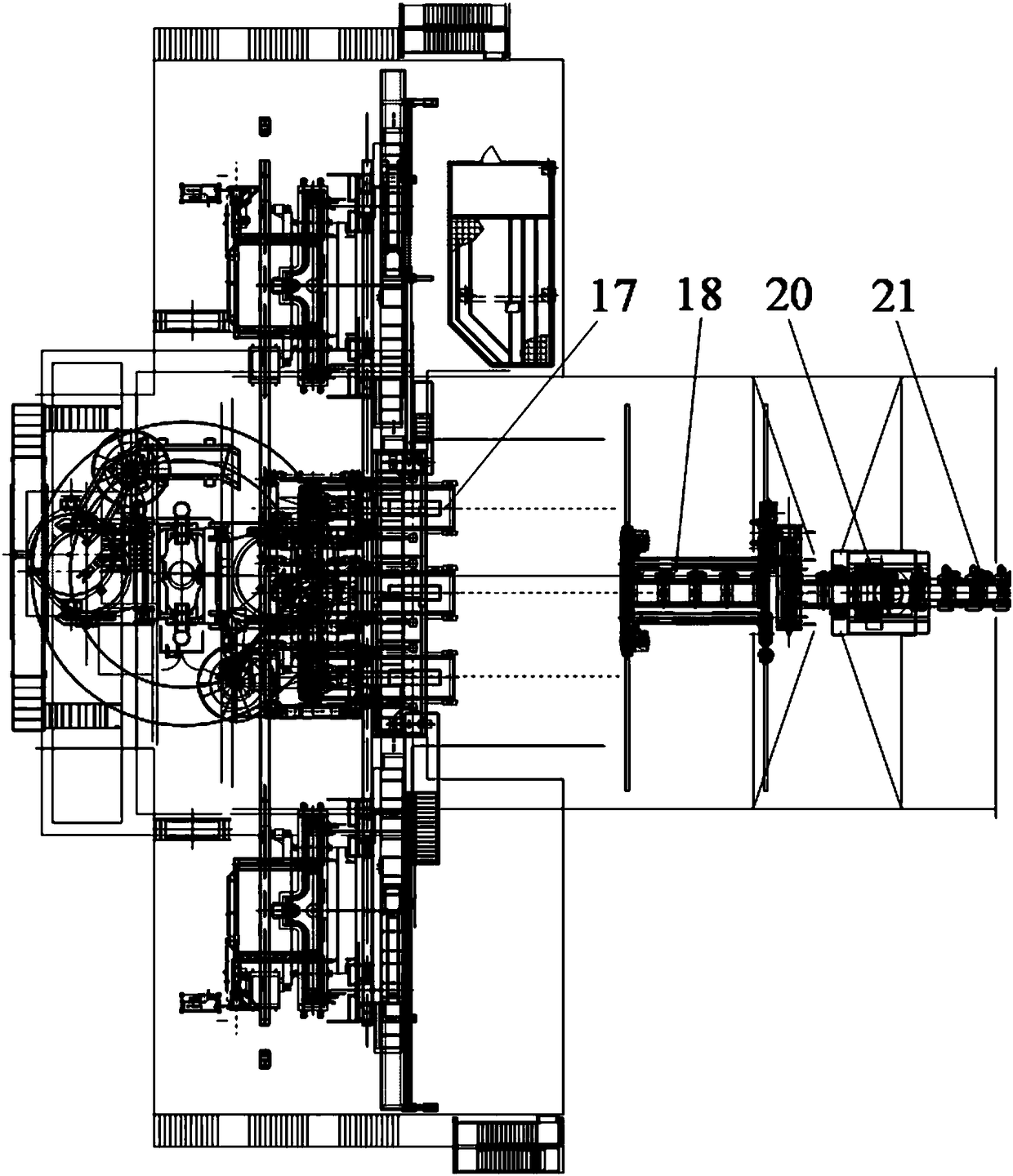

[0038] A vertical continuous casting production equipment for super-large round billets, comprising a ladle 1, a tundish 4, a crystallizer 6, a billet drawing system and a billet discharge system, the billet discharge system includes a billet discharge device 20, a billet combining The device 23, the billet lifting device 25 and the upper billet discharge roller table 28, the ladle 1, the tundish 4, the crystallizer 6 and the casting system are arranged in sequence from top to bottom. Corresponding to 20, the billet discharge device 20 and the billet combining device 23 are arranged on the left and right, the lower entrance of the billet lifting device 25 corresponds to the casting billet combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com