High-cleanness pre-filled syringe

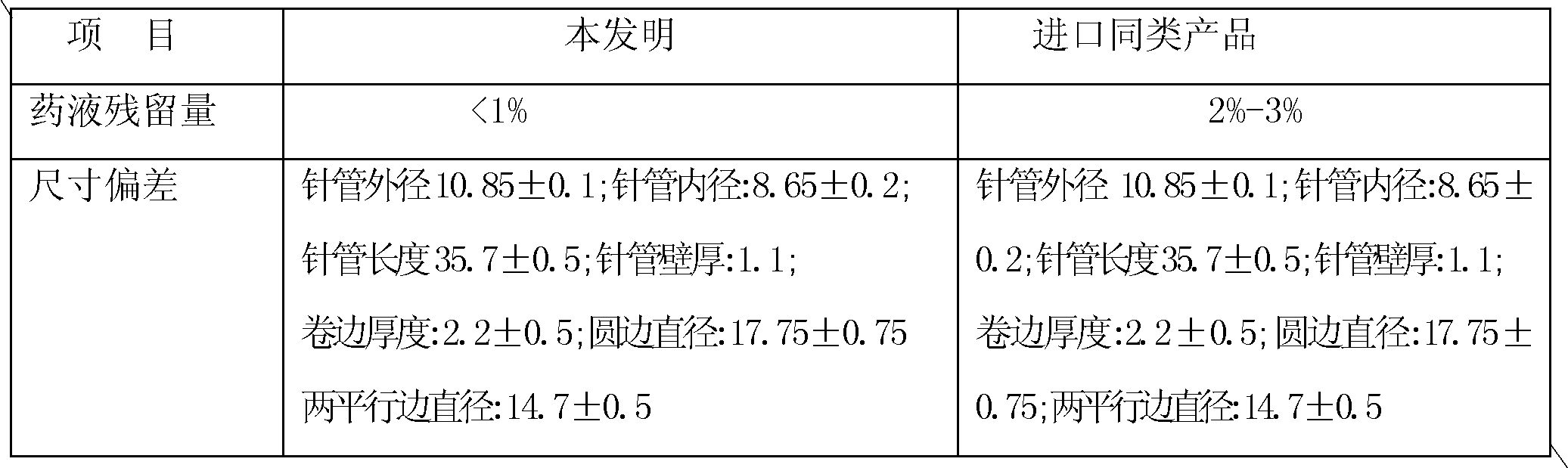

A high-cleanliness, syringe technology, applied in syringes, infusion sets, medical containers, etc., can solve the problem of no independent production of syringes, and achieve the effects of improving utilization, reducing residual volume, and ensuring dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The preparation method of the syringe comprises the following steps: 1) production of the syringe; 2) RTF treatment; 3) ETO sterilization; 4) acceptance inspection, packaging and storage.

[0026] Syringe production includes the following steps in a clean environment: glass molding, printing, baked siliconization, needle assembly and locking cone assembly. The unique baking and siliconization treatment process is adopted to improve the cleanliness of the syringe, which can effectively prevent the reaction between the syringe body and the filled liquid medicine and contaminate the medicine.

[0027] Glass forming includes the following steps: tube feeding→length fixing→heating→cutting→heating→cone forming→heating→curling preforming→heating→edge trimming→heating→trimming→cutting→inspection and packaging→warehousing. The key to controlling the heating quality is to control the flame temperature of each station by adjusting the pressure of natural gas and oxygen, so as to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com