Rotary holding and clamping mechanism and rotary holding and clamping trolley

A technology of holding clamps and trolleys, applied in the direction of lifting devices, etc., can solve problems such as high labor intensity, smashed forklifts, damage to material molds, etc., and achieve the effects of low material cost, convenient loading and unloading, and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

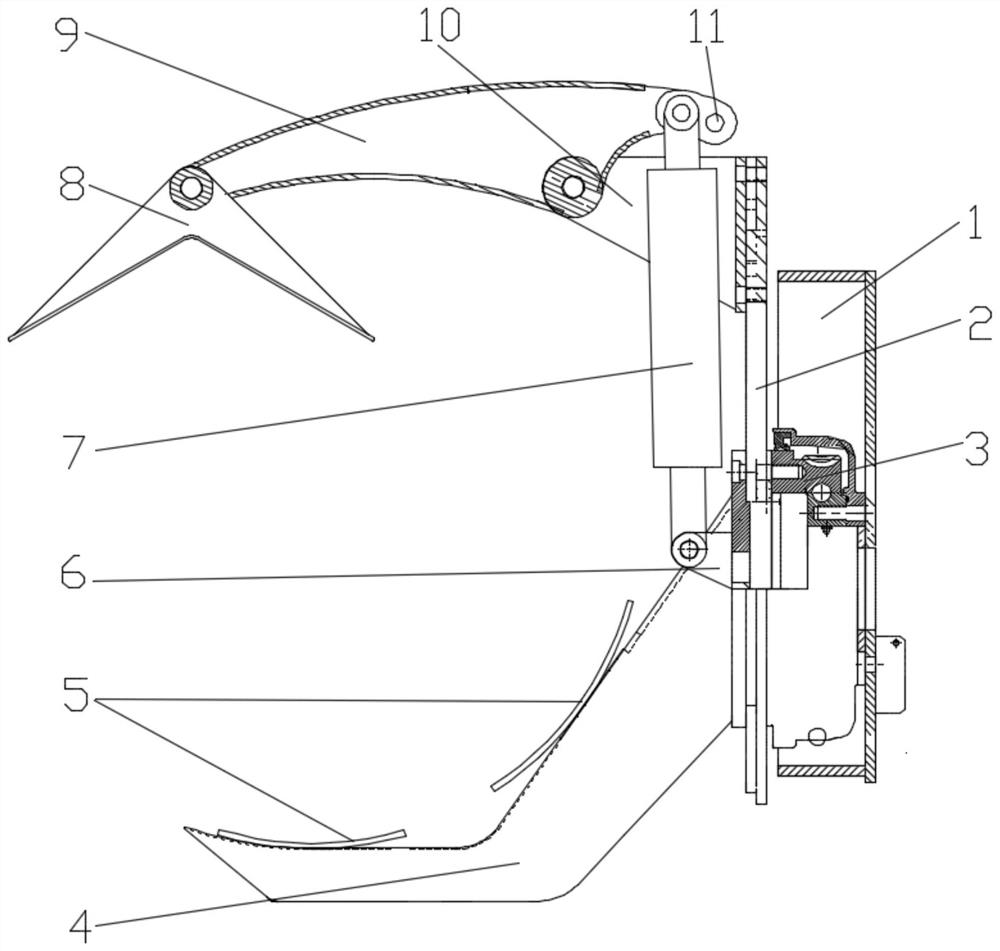

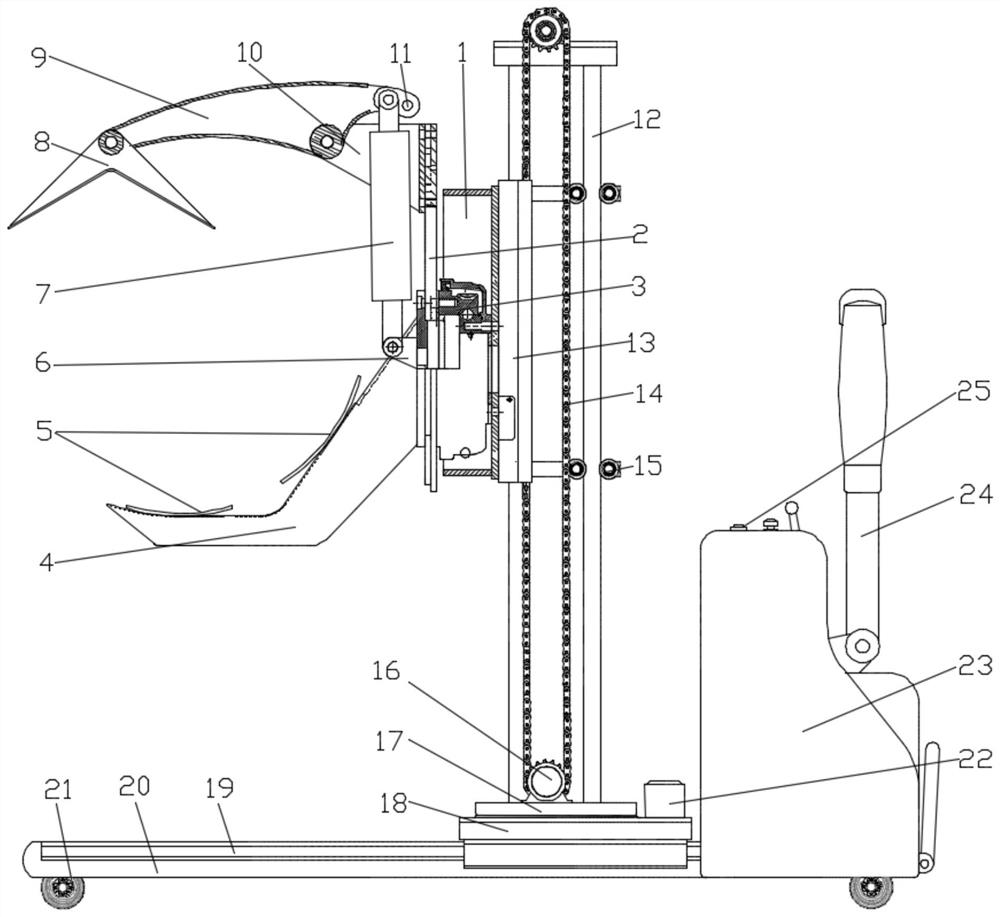

[0028] Such as figure 1 As shown, the rotating clamping mechanism provided in this embodiment includes a base 1 arranged on the body. The base 1 is provided with a turntable 2 and a rotating drive mechanism for driving the turntable 2 to rotate in a vertical plane. The turntable 2 is provided with There is a clamping mechanism, which includes a fixed arm 4 and a movable arm arranged on the turntable 2 facing each other; the cross section of the fixed arm 4 is "V"-shaped, and a free end of the fixed arm 4 is fixed to the turntable 2 connected, the open face of the fixed arm 4 faces the movable arm; it can be understood that the fixed arm 4 has a certain longitudinal width, and at least forms a line contact with the outer circumference of the coil, and the movable arm includes a hinge seat 10 fixedly connected with the turntable 2, the On the hinge base 10, a pivoted arm 9 is hinged, and the pivoted arm 9 is preferably arc-shaped. The end of the pivoted arm 9 away from the hinge...

Embodiment 2

[0033] Such as figure 1 As shown, the present embodiment is further optimized on the basis of embodiment 1, specifically:

[0034] A guard plate 5 with an arc-shaped cross section is fixed on both inner sides of the fixed arm 4 . Fixing the guard plate 5 with an arc-shaped cross-section on the two inner sides of the fixed arm 4 can effectively increase the contact area between the fixed arm 4 and the material roll, and further ensure the stability of the material roll clamp; especially after the material roll is stretched horizontally, The material roll is supported on the guard plate 5 of the fixed arm 4, which effectively increases the force-bearing area and makes the material roll horizontal support more stable, and the arc-shaped profiling guard plate plays a good role in limiting the material roll to avoid material Roll shifted or slipped during transfer.

[0035] One end of the pivoting arm 9 near the hinge base 10 is provided with a plurality of hinge holes 11 for hin...

Embodiment 3

[0038] Such as figure 1 with figure 2 As shown, the rotary clamping trolley provided in this embodiment includes the rotary clamping mechanism described in Embodiment 2, and also includes a carrying trolley and a rotating lifting mechanism. The carrying trolley includes a vehicle frame 20 and a console 23 connected to the vehicle frame 20 , the bottom of the vehicle frame 20 and the console 23 are provided with casters 21; the vehicle frame 20 is provided with a chassis 18, the rotating lifting mechanism is arranged on the chassis 18, and the base 1 is fixed on the rotating lifting mechanism; The side of the console 23 away from the vehicle frame 20 is hinged with a push-pull rod 24, the inner cavity of the console 23 is provided with a drive module, and the console 23 is provided with a control panel 25, and the drive module is respectively and rotated The clamping mechanism and the rotating lifting mechanism are connected, and the driving module is electrically connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com