Bearing outer ring washing process

A technology for bearing outer rings and bearings, applied in cleaning methods and tools, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as lack of cleanliness, difficult discharge of garbage, and high viscosity of cleaning kerosene. Achieve the effect of improving service life, reducing bearing noise and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below in conjunction with the examples, but the present invention is not limited to the content disclosed in the examples.

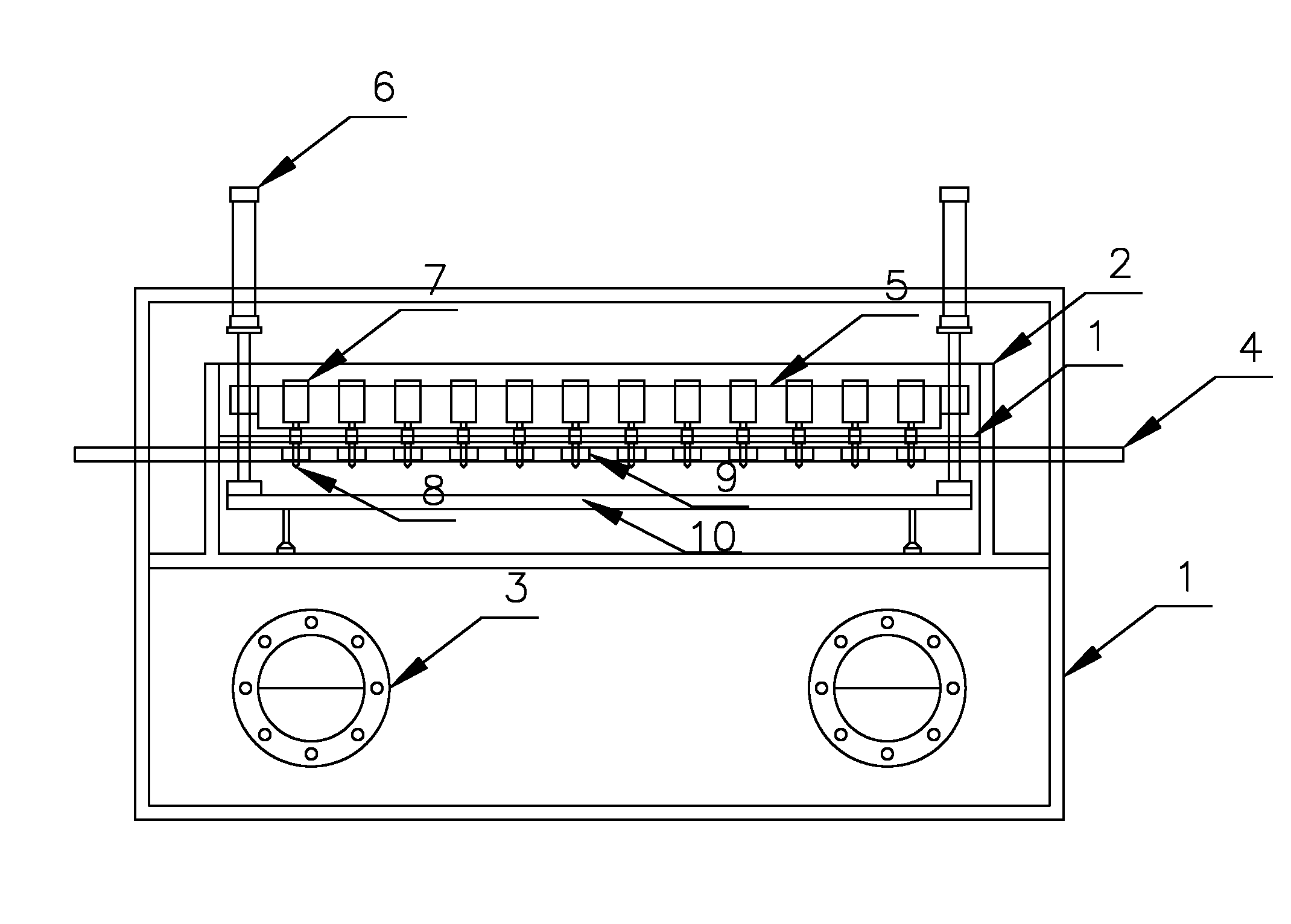

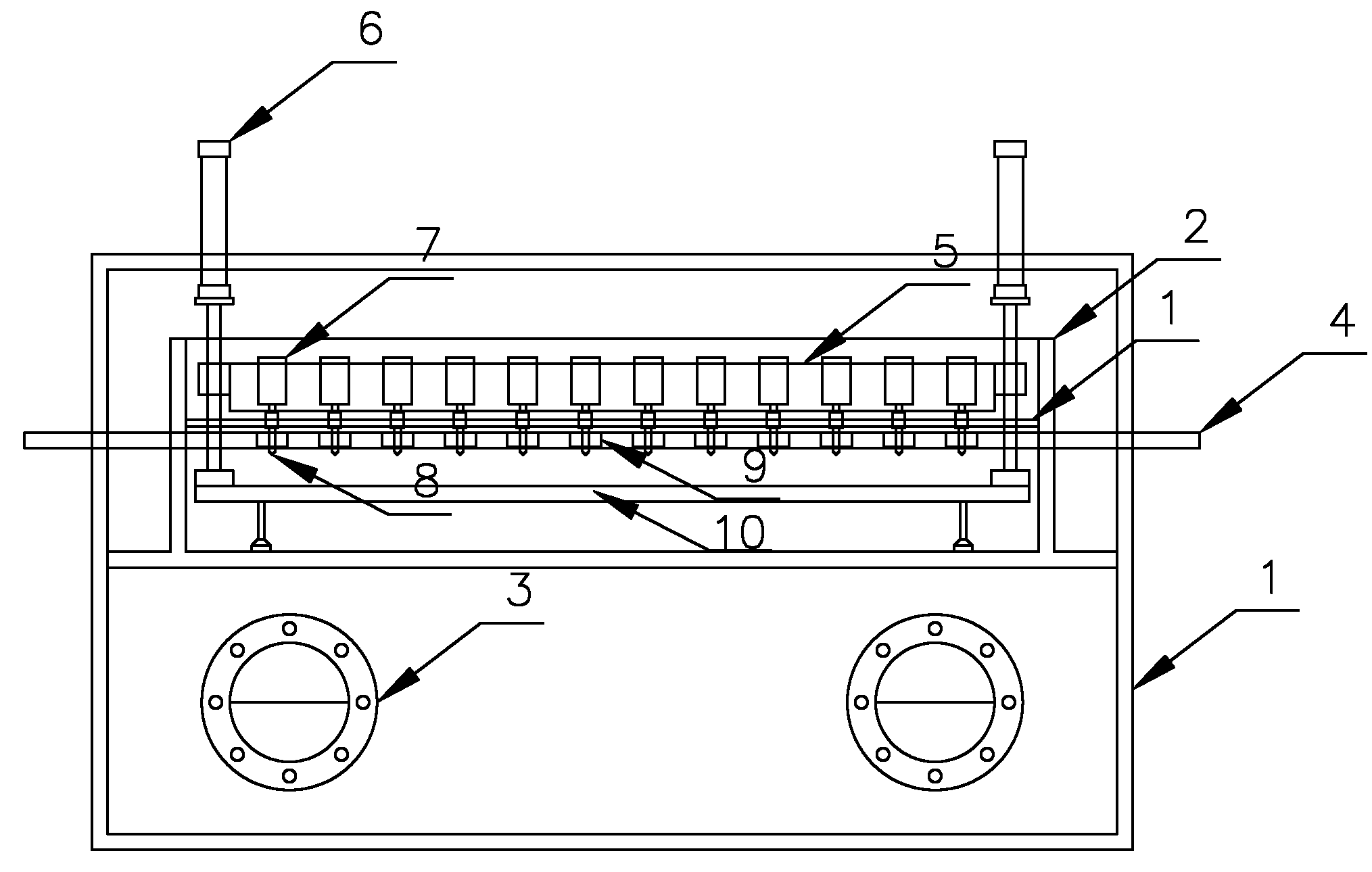

[0017] The bearing outer ring cleaning process described in the present invention includes the following steps: (1) brush cleaning uses a motor to directly drive the nylon brush to rotate and position the inner wall of the bearing outer ring and the raceway for cleaning; (2) an ultrasonic cleaning with Bearings are cleaned with an aqueous detergent as the cleaning medium, and ultrasonic waves with a frequency of 20-21kHz and a power of 1kW are used to clean the bearings cleaned by the brush; (3) The bearings cleaned by the ultrasonic wave in step (2) will Place it in the rinsing tank, and use the filtered tap water to rinse it; (4) The second ultrasonic cleaning uses the bearing water agent cleaning agent as the cleaning medium, and uses an ultrasonic wave with a frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com