Treatment device for pre-cleaning of tempered glass outer wall

A tempered glass and processing device technology, applied in cleaning methods using tools, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve the problems of glass multiple pinholes, film removal, etc., to improve the filtering effect, Improved efficiency and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

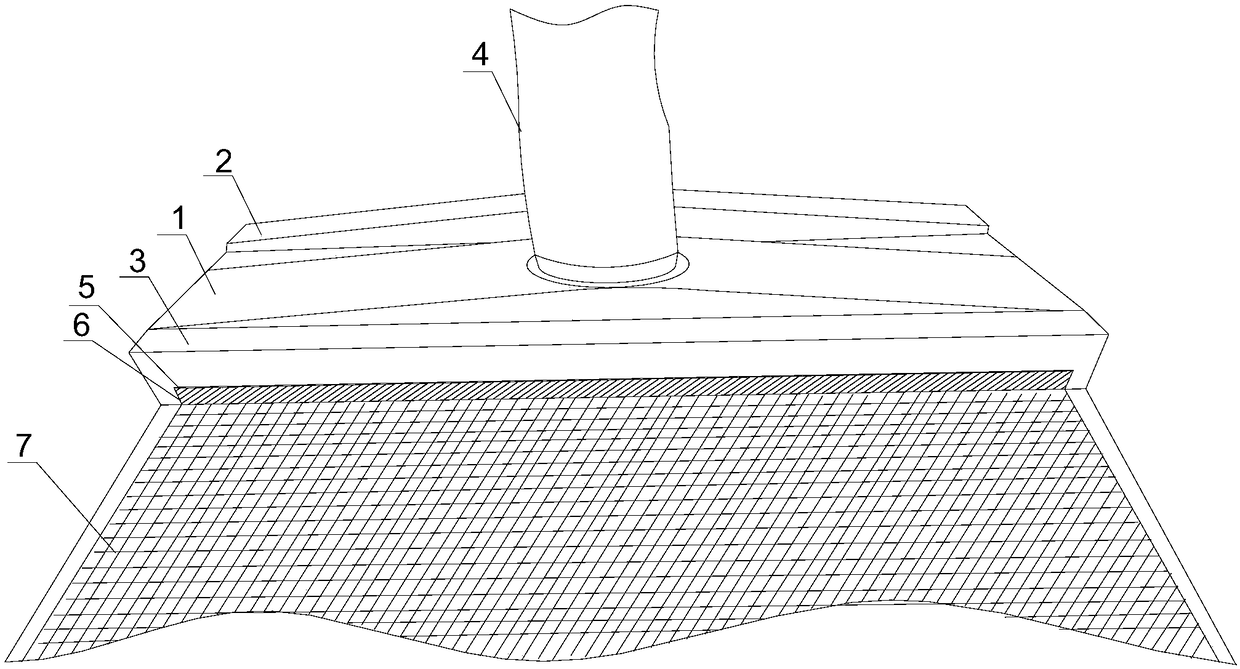

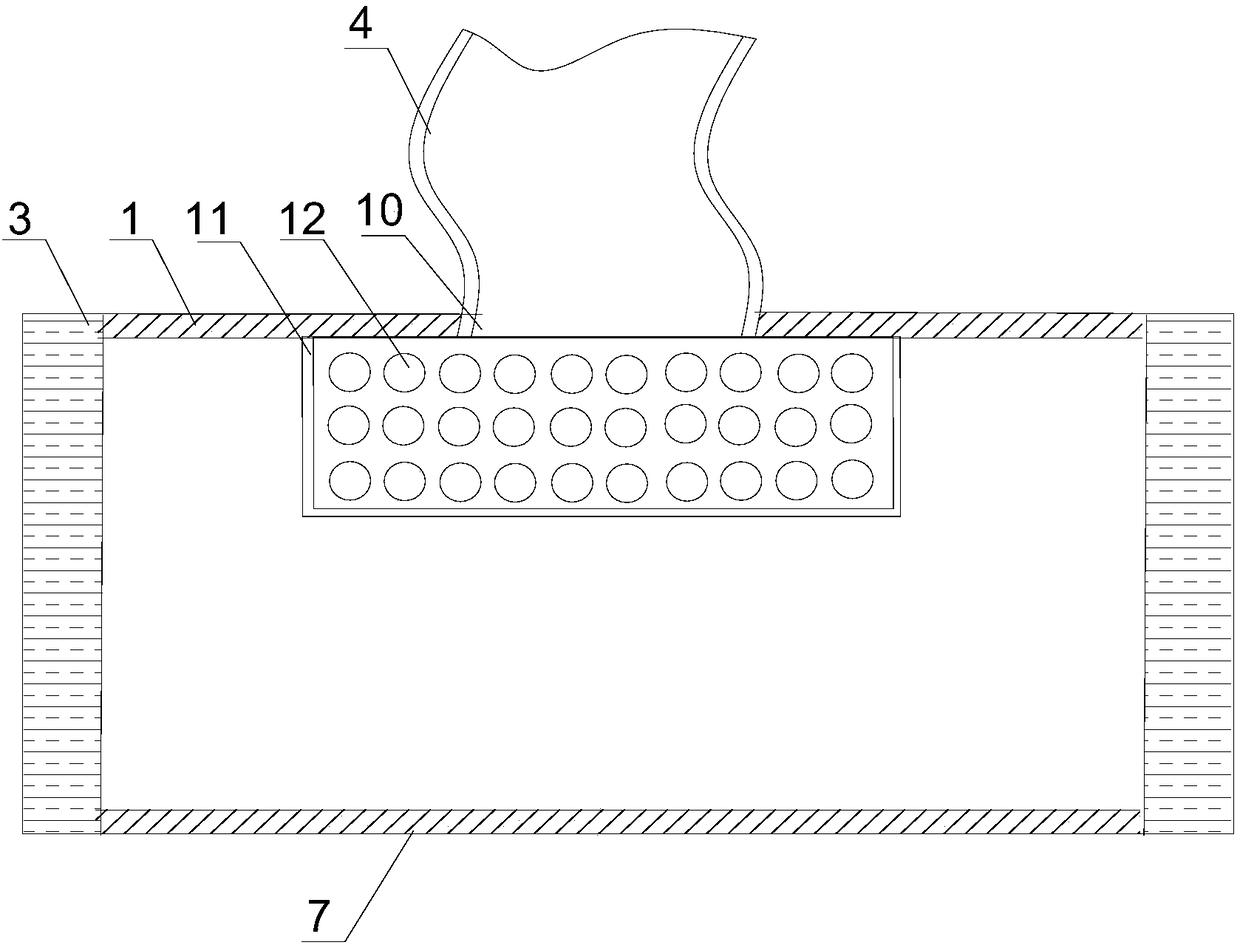

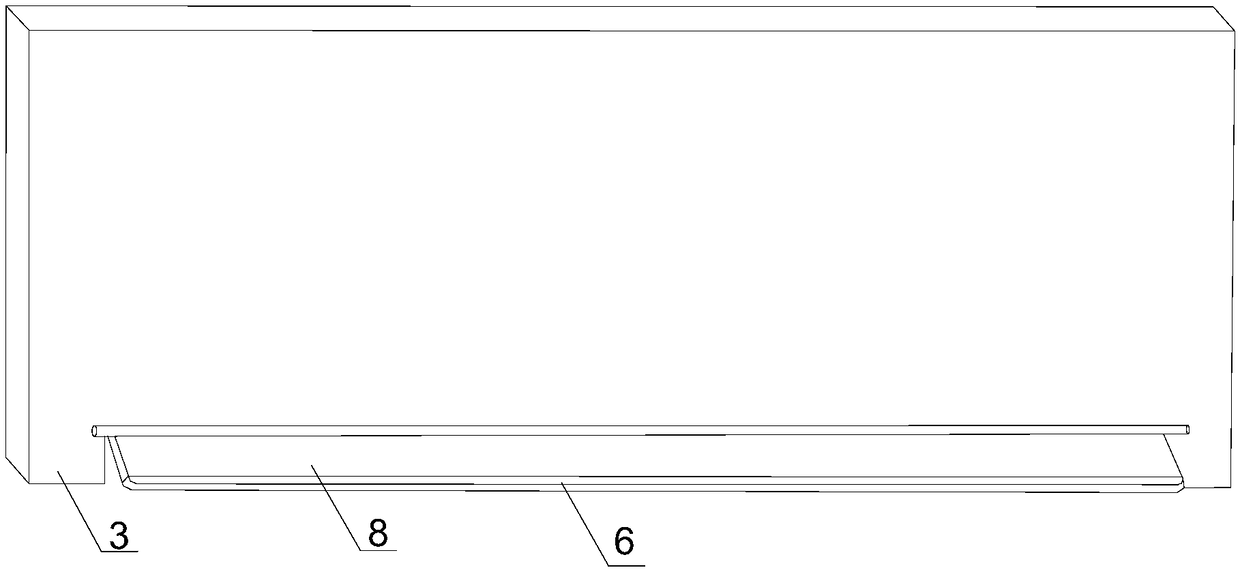

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the treatment device for pre-cleaning the outer wall of tempered glass in the present invention includes an adsorption plate 1, an adsorption hose 4, a conveyor and an exhaust fan. The adsorption plate 1 is arranged on the conveyor, and the adsorption plate 1 is provided with an air outlet 10. One end of the adsorption hose 4 is connected to the air outlet 10, the other end of the adsorption hose 4 is connected to the exhaust fan, and a first baffle 2 and a second baffle 3 are arranged at both ends of the adsorption plate 1, so that The first baffle plate 2, the second baffle plate 3 and the adsorption plate 1 constitute an adsorption chamber, the lower end of the second baffle plate 3 is provided with a rectangular groove 5, and a feed plate 6 is rotated on the inner wall of the second baffle plate 2, The feed plate 6 covers the rectangular groove 5, and the first baffle plate 2 is provided with a U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com