Non-alcoholic beverage bottle inside and outside cleaning and disinfecting device

A cleaning and disinfection, non-alcoholic technology, which is applied in the direction of disinfection, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of incomplete cleaning and low efficiency of manual cleaning, and achieve the effect of improving the qualified rate, improving efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

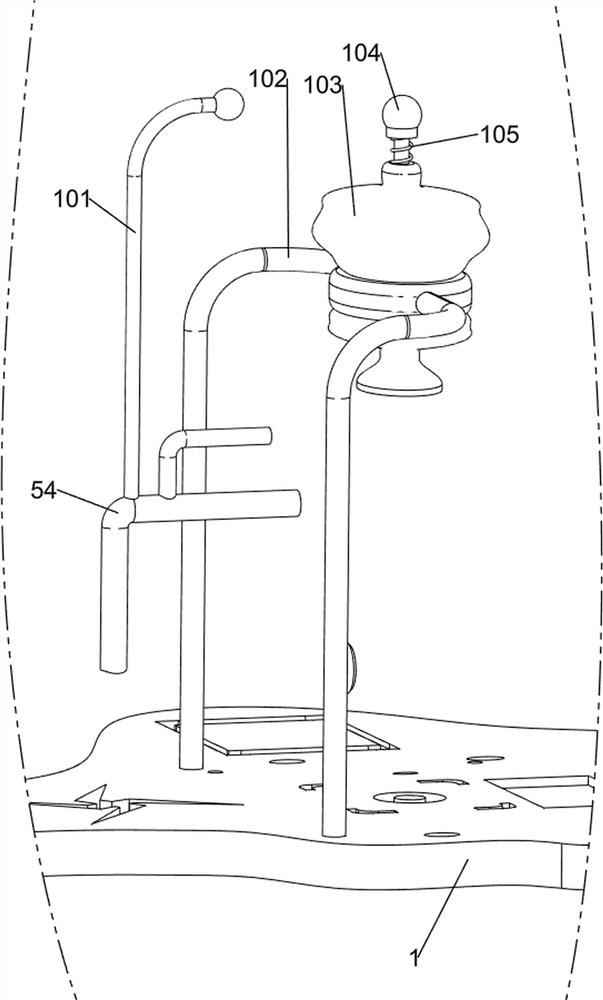

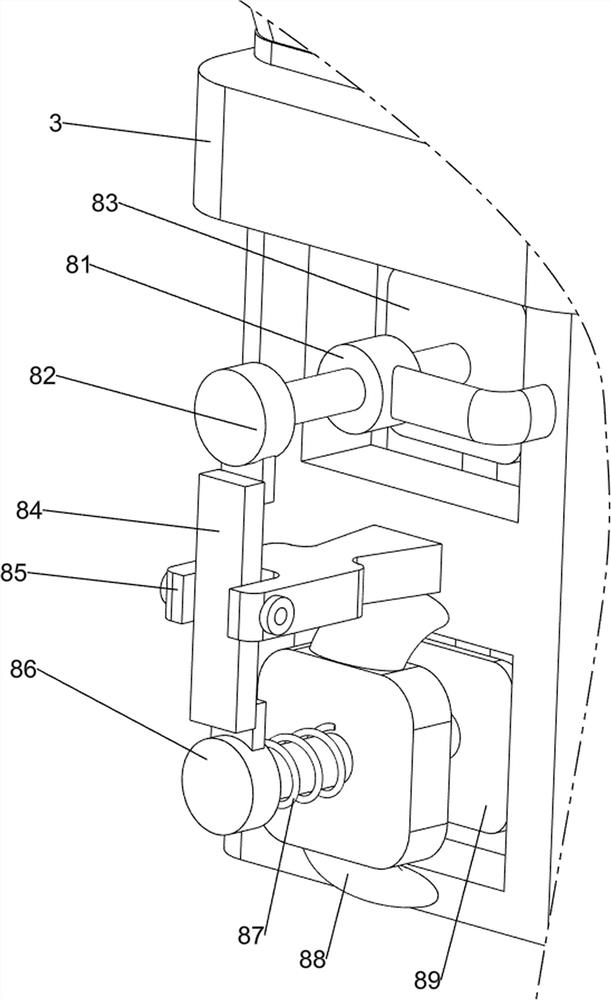

[0084] A device for cleaning and disinfecting the inside and outside of non-alcoholic beverage bottles, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 8 As shown, it includes a bottom plate 1, a workbench 2, a blanking frame 3, a feeding mechanism 4, a cleaning mechanism 5, and a rotating mechanism 6. A worktable 2 is placed in the middle of the upper side of the bottom plate 1, and a blanking frame 3 is arranged on the upper side of the bottom plate 1. , The upper right side of the base plate 1 is provided with a feeding mechanism 4 , the upper side of the base plate 1 is provided with a cleaning mechanism 5 , and the workbench 2 is provided with a rotating mechanism 6 .

[0085] When people are going to clean and disinfect the inside and outside of the drink bottle, they first put the drink bottle into the blanking frame 3, and the drink bottle will fall into the rotating mechanism 6. At this time, manually push the cleaning mech...

Embodiment 2

[0087] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 8 with Figure 9 As shown, the feeding mechanism 4 includes a first bracket 41, a first sliding rod 42, a bearing 43 and a rotating disk 44, two first brackets 41 are arranged on the right side of the upper front part of the bottom plate 1, and the first bracket 41 tops on the front and rear sides The sliding type is provided with a first sliding rod 42, the left side of the first sliding rod 42 is provided with a bearing 43, and the left side of the bearing 43 is provided with a turntable 44.

[0088] When people are going to clean and disinfect the inside and outside of the drink bottle, they first put the drink bottle into the blanking frame 3, and the drink bottle will fall into the rotating mechanism 6. At this time, when the cleaning mechanism 5 is manually pushed to the right to a suitable position, Stop pushing the cleaning mechanism 5, now manu...

Embodiment 3

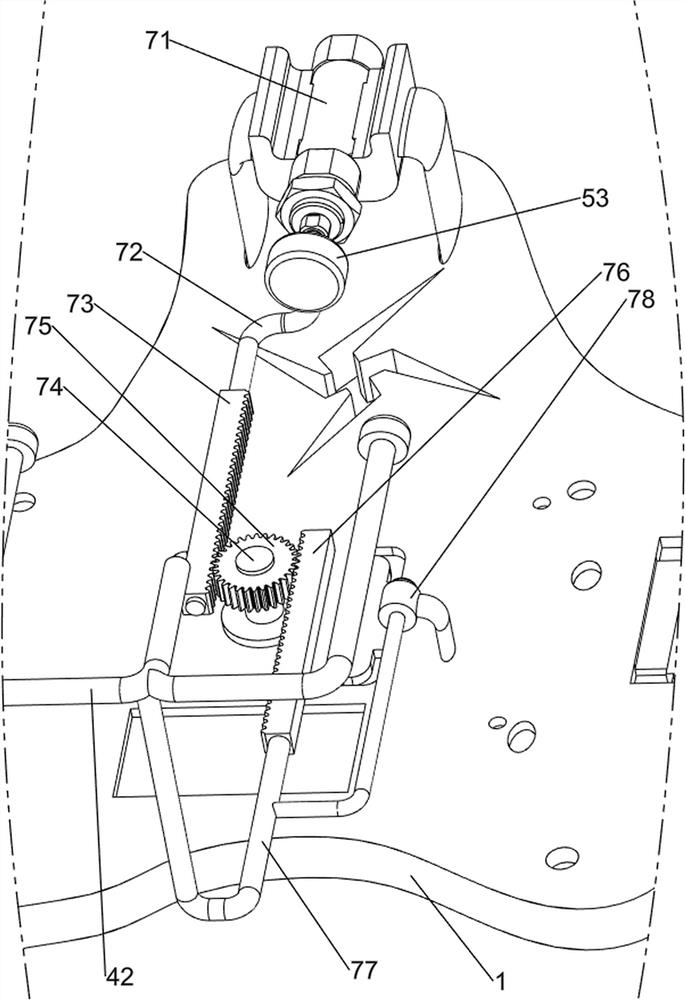

[0094] On the basis of Example 2, such as figure 1 , Figure 5 , Image 6 with Figure 7 As shown, push mechanism 7 is also included, and push mechanism 7 includes cylinder 71, second connecting rod 72, first spur rack 73, rotating shaft 74, spur gear 75, second spur rack 76, third slide bar 77 And the 3rd support 78, bottom plate 1 left upper part is provided with cylinder 71, and the output shaft of cylinder 71 is connected with connecting block 53, and connecting block 53 lower side is provided with second connecting rod 72, and the right side of second connecting rod 72 is provided with the first Straight rack 73, bottom plate 1 middle part upper side is rotationally connected with rotating shaft 74, and rotating shaft 74 is provided with spur gear 75, and spur gear 75 meshes with the first straight rack 73, and the first slide bar 42 middle part lower side is provided with the first Three sliding rods 77, the left side of the third sliding rod 77 is provided with a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com