Yogurt fermentation tank

A fermenter and yogurt technology, applied in the directions of milk preparations, dairy products, chemical instruments and methods, etc., can solve the problems of incomplete cleaning, poor tissue state, and yogurt texture damage, and improve the cleaning effect and cleaning efficiency. , The effect of overcoming the large viscosity loss and reducing the viscosity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

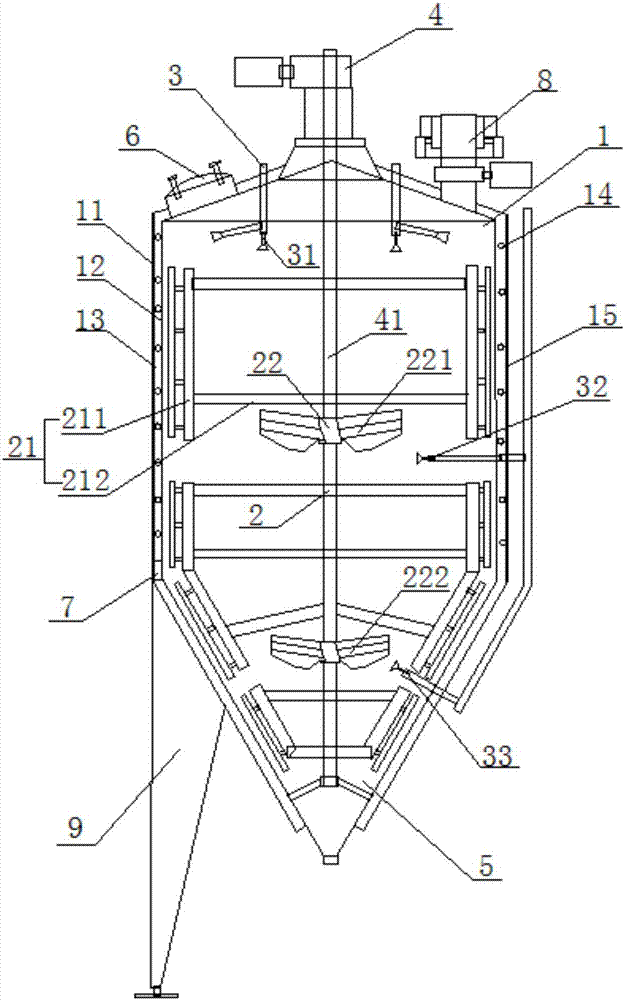

[0022] In order to further describe the present invention, the specific implementation of a yogurt fermentation tank will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] like figure 1 A yogurt fermentation tank shown includes a tank body 1, a stirring device 2, a CIP cleaning device 3, and a motor transmission device 4. The motor transmission device 4 is installed on the top of the tank body 1, and the bottom of the tank body 1 is set as a conical bottom 5. The shape vertex angle is 30°~90°, preferably designed to be 60°. The height of the conical bottom 5 at the bottom of the tank body 1 accounts for 1 / 3-1 / 2 of the whole tank body 1 .

[0024] The tank body 1 includes an inner wall 11 and an outer wall 12 which are fitted and fixed, and a hollow interlayer 13 is arranged between the inner wall 11 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com