Stratified injection tubular pile

The technology of a pipe string and a poly-oil pipe, which is applied in the field of polymer flooding oil production, can solve the problems of unmeasurable flow rate and viscosity, blockage of a single pipe, and difficulty in casting and fishing, so as to reduce the serious shear degradation of the polymer and reduce the delamination. Error, the effect of real and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

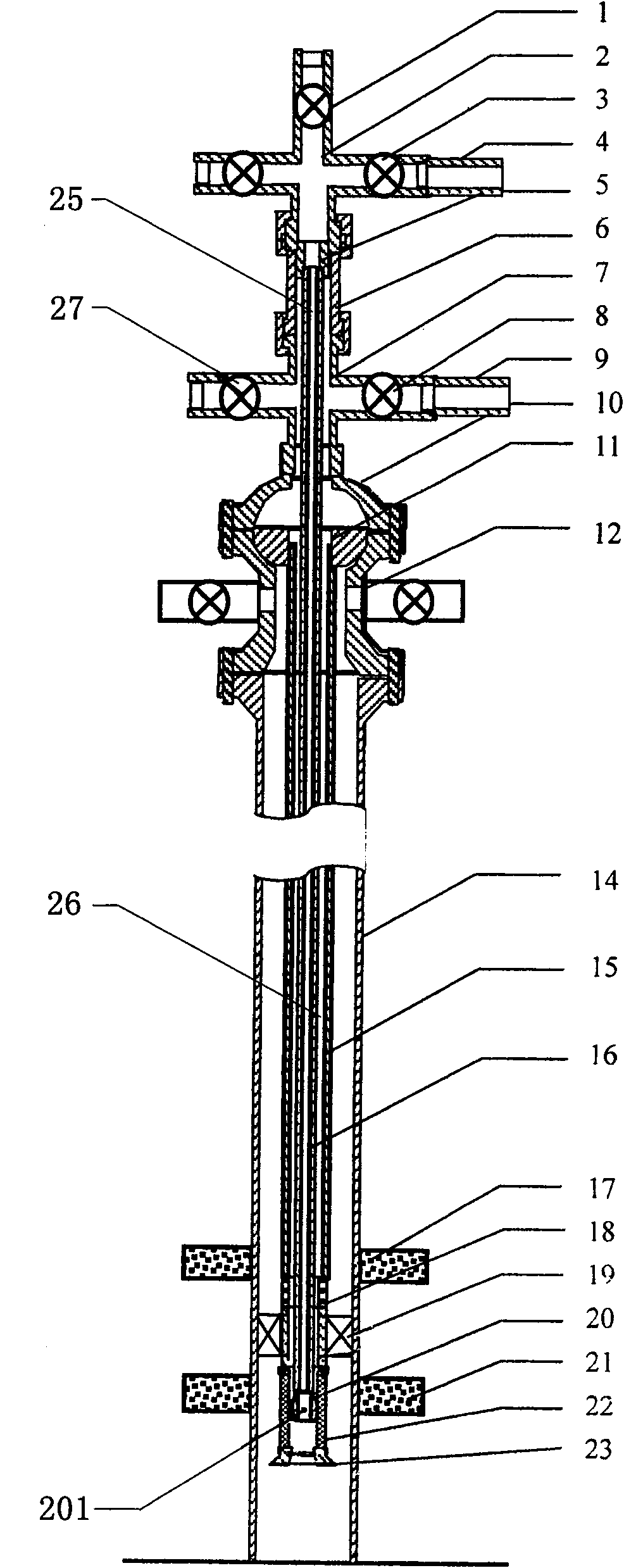

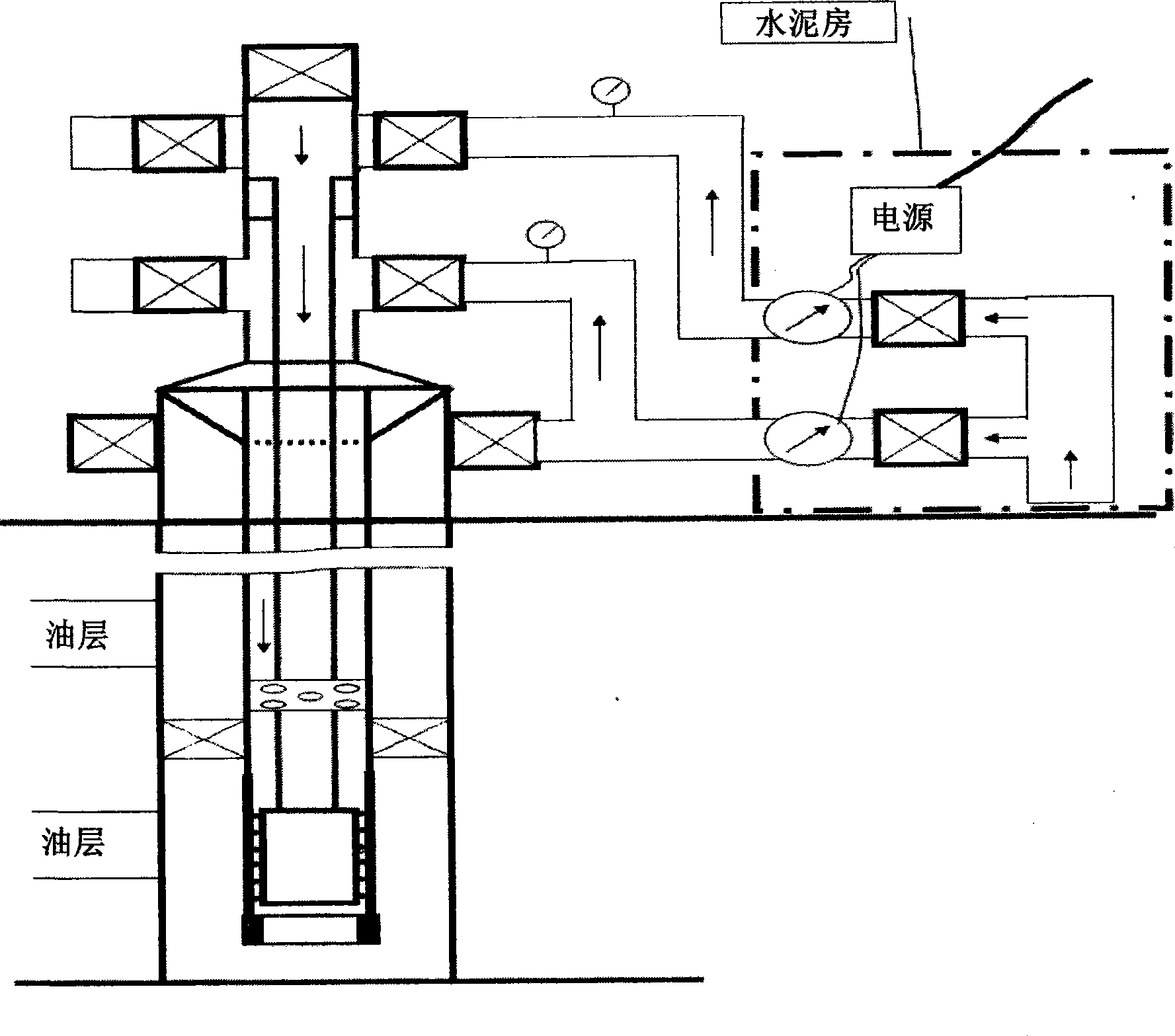

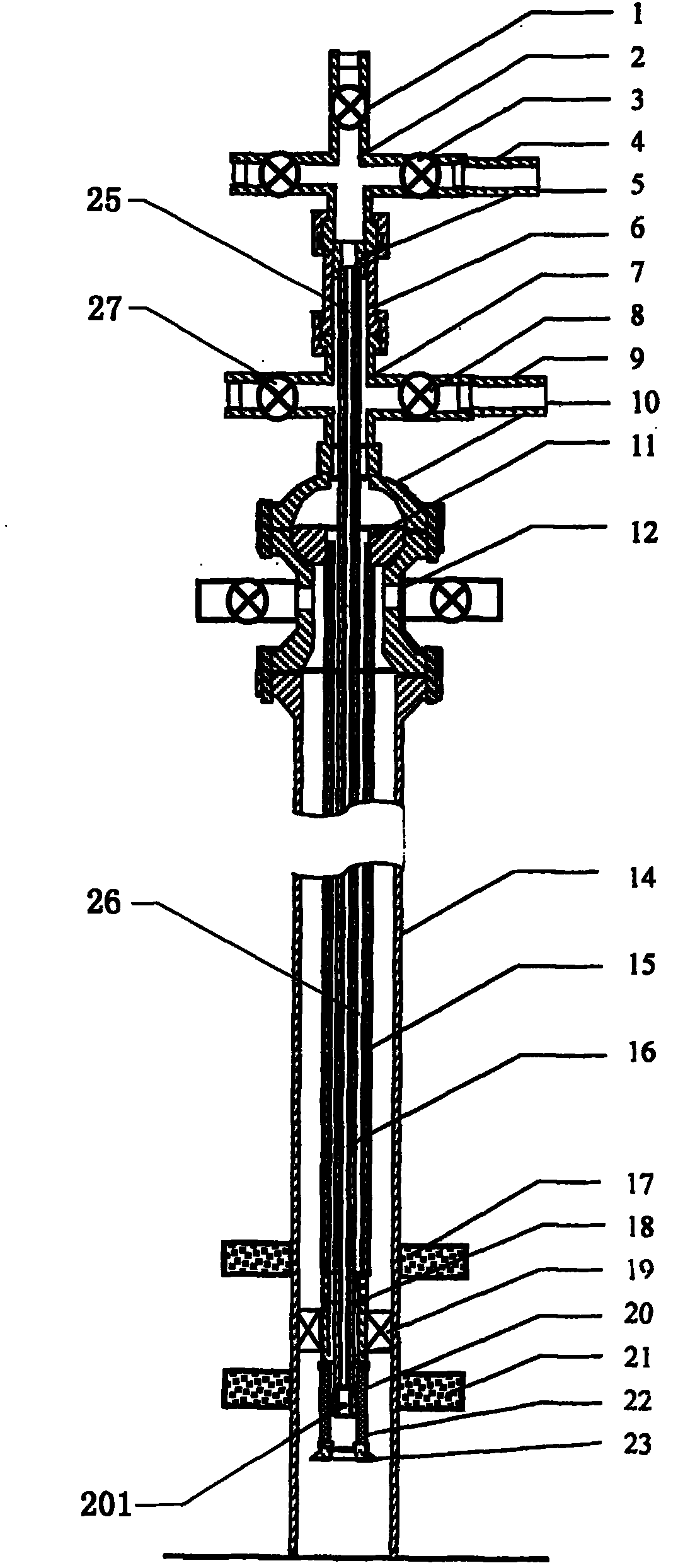

[0029] like figure 1 and figure 2 As shown, the layered polymer injection string of the present invention includes a polymer injection tubing for transporting polymer solution, wherein the polymer injection tubing further includes an outer polymer injection tubing 15 and an inner polymer injection tubing built in the outer polymer injection tubing 15. The oil pipe 16 and the inner flow channel 25 and the outer flow channel 26 leading to different oil layers are respectively formed in the inner poly oil injection pipe 16 and the annular space between the inner poly oil injection pipe 16 and the outer poly oil injection pipe 15 . Compared with the prior art, due to the use of double flow channels to divide the flow on the ground, problems such as blockage and difficult fishing caused by the use of downhole distributors are eliminated.

[0030] The lower end of the inner channel 25 communicates with the lower poly-injected oil layer 21 through a close-fitting compensator. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com