Flow plug for chemical flooding stratified injection

A technology of chemical flooding and choke, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of large loss of chemical fluid viscosity, unsatisfactory chemical flooding effect, and inability to maintain chemical fluid stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

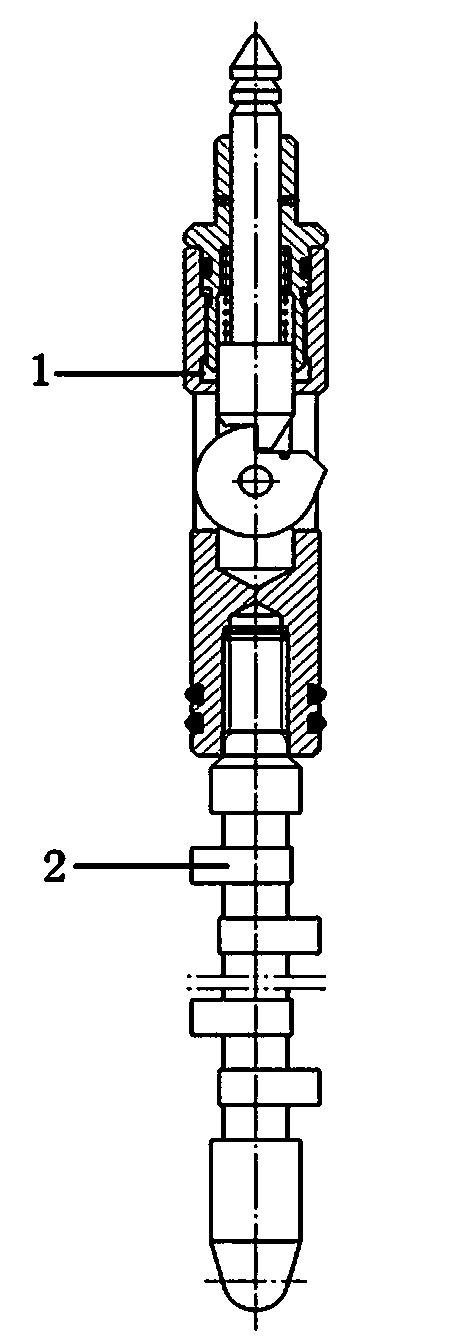

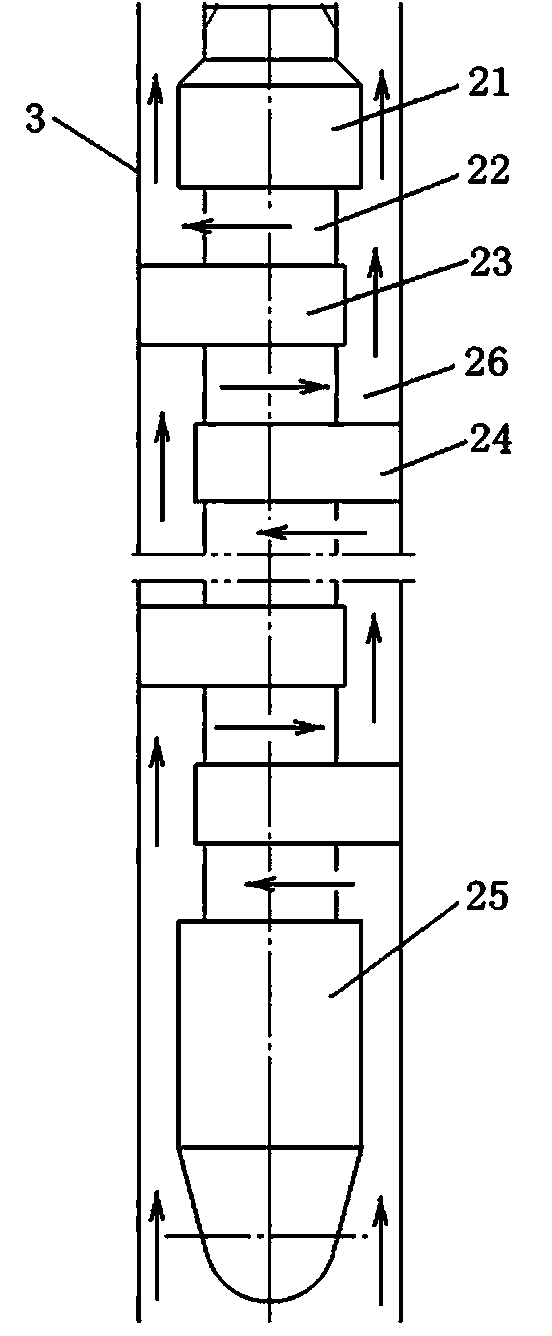

[0014] see Figure 1-7 , the present invention is a layered injection choke for chemical flooding, which is composed of an upper joint 1 and a choke core 2, wherein the upper joint 1 and the choke core 2 are screwed together and installed in a chemical flooding injection device (existing Technology) in the offset hole 3, cooperate with the smooth inner surface of the offset hole 3 to form a labyrinth flow channel 26.

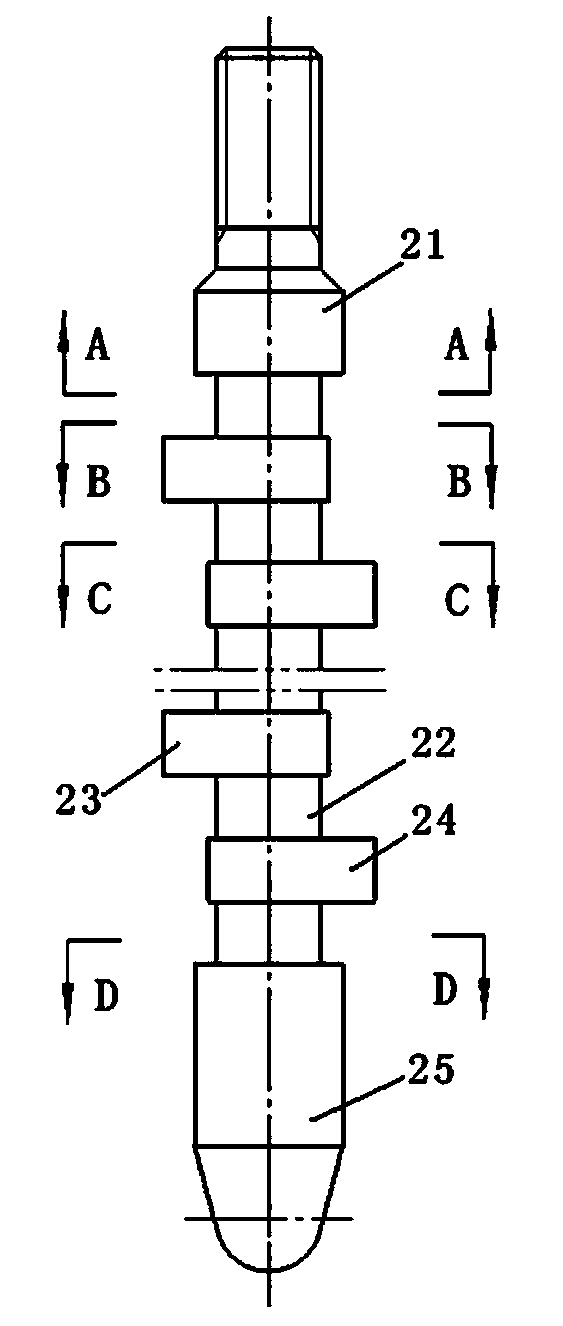

[0015] The choke core 2 is composed of an inlet end 25, a center column 22, a left stopper 23, a right stopper 24 and an outlet end 21 arranged on the same axis, and the top and bottom ends of the center column 22 are respectively connected with cross-sectional shapes Outlet port 21 and inlet port 25 are waist-shaped. A plurality of left stoppers 23 and right stoppers 24 are equidistantly connected to the central column 22 between the inlet end 25 and the outlet end 21 . The left block 23 and the right block 24 are in the shape of a circular plate with a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com