A low floating fiber, high impact strength polyamide composite material

A composite material, high-impact technology, applied in the field of engineering plastics, can solve the problems of heat resistance decline, mechanical properties decline, precipitation, etc., achieve high impact strength performance, and improve the effect of floating fiber problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

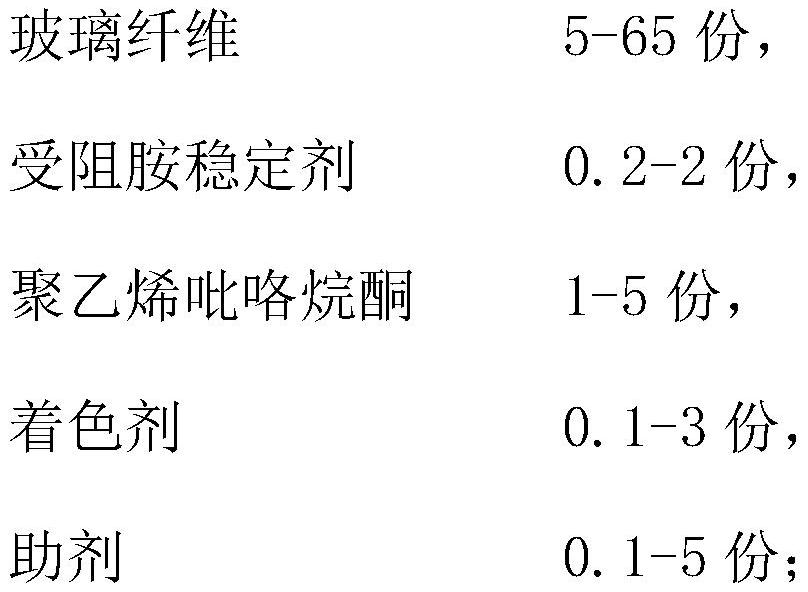

Method used

Image

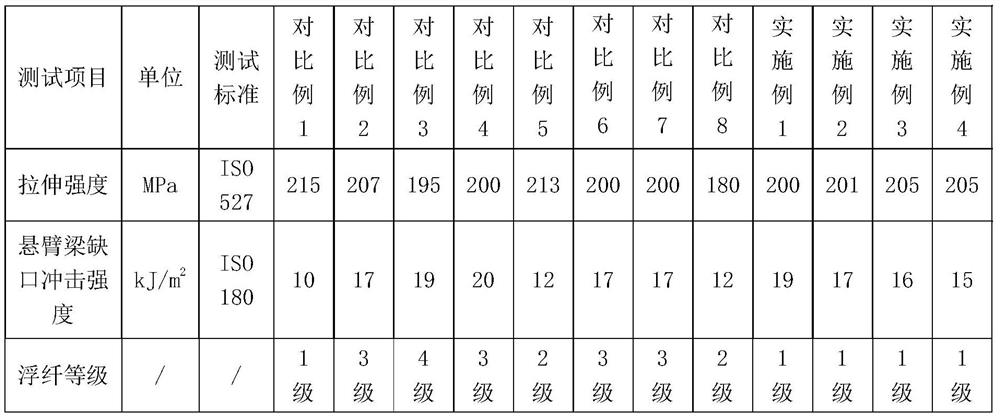

Examples

Embodiment 1

[0032] A low-floating fiber, high-impact-strength polyamide composite material, the composite material is made from the following raw materials by weight: 19 parts of GFZ1700, 37 parts of GFZ3500 powder, 40 parts of ECS10-03-568H, S-EED FF 1 parts, PVPK-90 2 parts, M717 0.4 parts, IRGANOX 1098 0.2 parts, TR044W 0.4 parts.

[0033] A preparation method of low-floating fiber, high-impact-strength polyamide composite material, comprising the following steps: mixing polyamide resin A, hindered amine stabilizer, polyvinylpyrrolidone, colorant and auxiliary agent for 10 minutes, and then mixing the obtained mixture Add to the feeding hopper of the twin-screw extruder, add glass fiber from the feeding port of the sixth section of the screw barrel, crush the polyamide resin B into powder, and then add it from the feeding port of the fifth section of the screw barrel. After plasticizing, extruding after melting, drawing, cooling, and pelletizing, the low-floating fiber, high-impact-str...

Embodiment 2

[0036] A low-floating fiber, high-impact-strength polyamide composite material, the composite material is made from the following raw materials by weight: 28 parts of GFZ1700, 28 parts of GFZ3500 powder, 40 parts of ECS10-03-568H, S-EED FF 1 parts, PVPK-90 2 parts, M717 0.4 parts, IRGANOX 1098 0.2 parts, TR044W 0.4 parts.

[0037] The preparation method of a low-floating fiber, high-impact-strength polyamide composite material is the same as that in Example 1.

Embodiment 3

[0039] A low-floating fiber, high-impact-strength polyamide composite material, the composite material is made from the following raw materials by weight: 33 parts of GFZ1700, 23 parts of GFZ3500 powder, 40 parts of ECS10-03-568H, S-EED FF 1 parts, PVPK-90 2 parts, M717 0.4 parts, IRGANOX 1098 0.2 parts, TR044W 0.4 parts.

[0040] The preparation method of a low-floating fiber, high-impact-strength polyamide composite material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com