An AES colophony with high impact and its preparing method

A high-impact, resin-based technology, applied in the field of AES resin and its preparation, can solve the problems of large amount of solvent, complex process and high energy consumption, and achieve the effects of excellent comprehensive performance, simple process and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

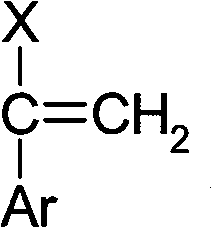

AI Technical Summary

Problems solved by technology

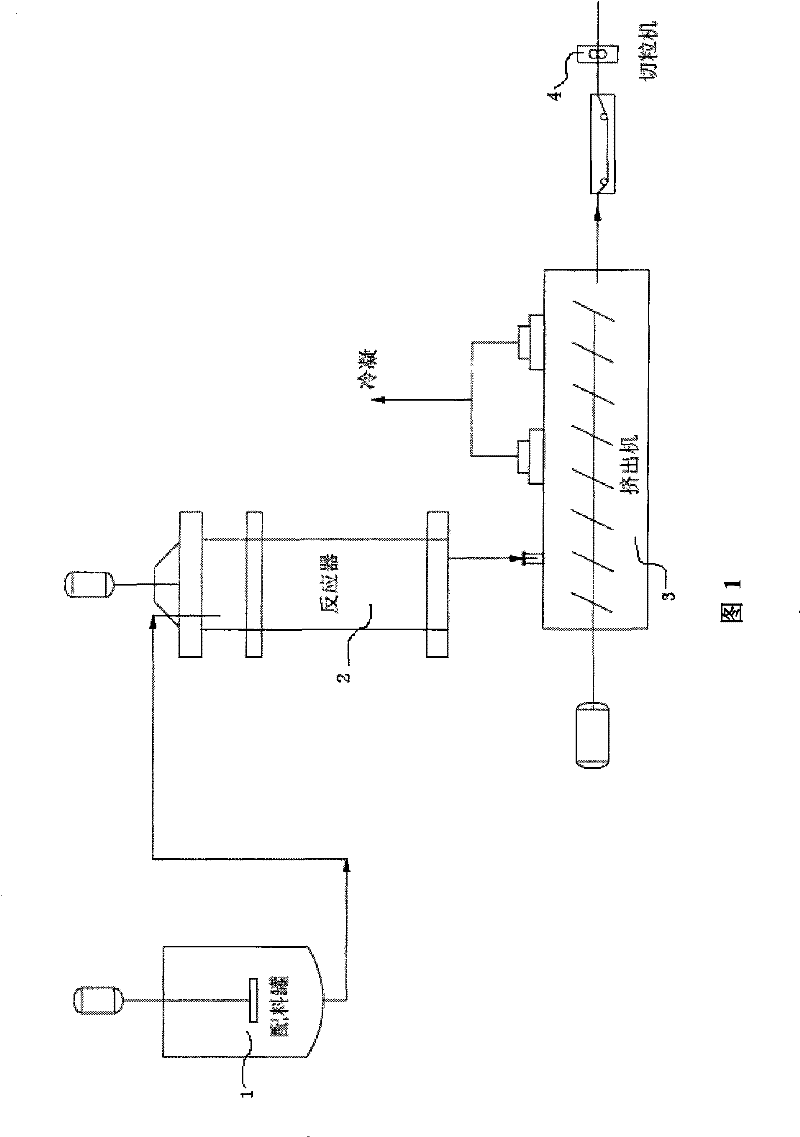

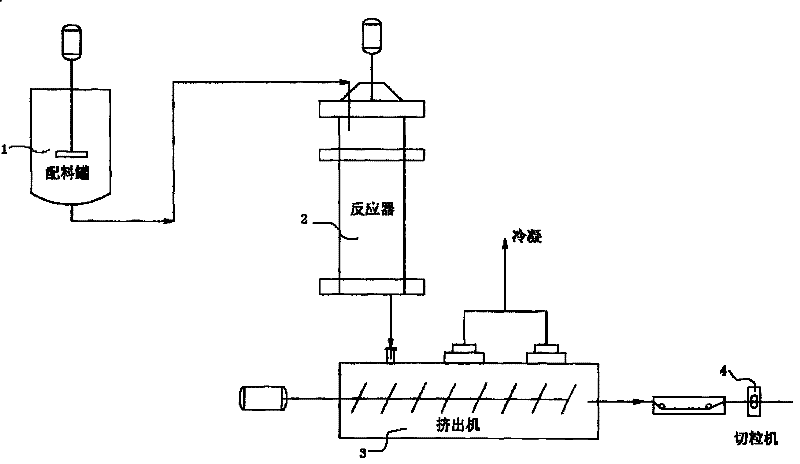

Method used

Image

Examples

Embodiment 1

[0036] Add 0.9kg of ethylbenzene and 2.55kg of styrene into the rubber dissolving tank, start stirring, then add 0.5kg of Keltan51 EPDM rubber and 0.1kg of butadiene rubber AE 55 rubber through the glue inlet, stir at room temperature for 8 hours and then add 0.9kg Acrylonitrile, 0.05kg mineral oil, 25g antioxidant, 15g chain transfer agent mercaptan and 1.5g tert-butyl perneodecanoate. Continue to stir and disperse for 30 minutes, and the batching is completed.

[0037] The ingredients are pumped into the reactor. The pressure in the reactor is controlled above 0.5MPa; the reaction temperature is 100°C / 2h; 110°C / 2h; 121°C / 2h and 145°C / 2h through different stages; the stirring speed of the reactor is 250 / 350 through different stages / 100 / 60rpm; the volume of the reactor used is 6L.

[0038] After the reaction was completed for 8 hours, the reaction melt was granulated by a devolatilization extruder to obtain a product suitable for injection molding. The corresponding ASTM stan...

Embodiment 2

[0040] Add 0.7kg of toluene, 0.2kg of acetone and 2.55kg of styrene into the rubber dissolving tank, start stirring, and then add 0.5kg of Keltan51 EPDM rubber and 0.1kg of butadiene rubber AE35 rubber into the rubber dissolving tank through the glue inlet, at room temperature Stir the material in the tank, add 0.9kg acrylonitrile, 0.1kg butyl acrylate, 0.05kg mineral oil, 25g antioxidant, 15g chain transfer agent mercaptan and 1.5g tert-butyl perbenzoate after 8 hours. Continue to stir and disperse for 30 minutes, and the batching is completed.

[0041] The ingredients are pumped into the reactor. The reaction pressure is controlled above 0.5MPa; the reaction temperature is 100°C / 2h; 110°C / 2h; 121°C / 2h; 145°C / 2h; the stirring speed of the reactor is 250 / 350 / 100 through different stages / 60rpm The reactor volume used is 6L.

[0042] After the reaction was completed for 8 hours, the reaction melt was granulated by a devolatilization extruder to obtain a product suitable for i...

Embodiment 3

[0044] Add 0.7kg of toluene, 0.2kg of acetone and 2.55kg of styrene into the rubber dissolving tank, start stirring, and add 0.5kg of Keltan51 EPDM rubber and 0.1kg of butadiene rubber AE55 rubber into the above rubber dissolving tank through the glue inlet, at room temperature After stirring for 8 hours, 0.9 kg of acrylonitrile, 0.05 kg of mineral oil, 25 g of antioxidant, 15 g of chain transfer agent mercaptan and 1.5 g of tert-butyl perneodecanoate were added. Continue to stir and disperse for 30 minutes, and the batching is completed.

[0045] The ingredients are pumped into the reactor. The reaction pressure is controlled above 0.8MPa; the reaction temperature is 105°C / 2h; 115°C / 2h; 125°C / 2h; 150°C / 2h; the stirring speed of the reactor is 150 / 250 / 120 through different stages / 60rpm; the volume of the reactor used is 6L.

[0046] After the reaction was completed for 8 hours, the reaction melt was granulated by a devolatilization extruder to obtain a product suitable for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com