High-purification-treatment automatic production line of steel drum

An automatic production line, purification technology, applied in chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of waste of manpower and material resources, uncleanness, etc., and achieve the effect of meeting the requirements of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

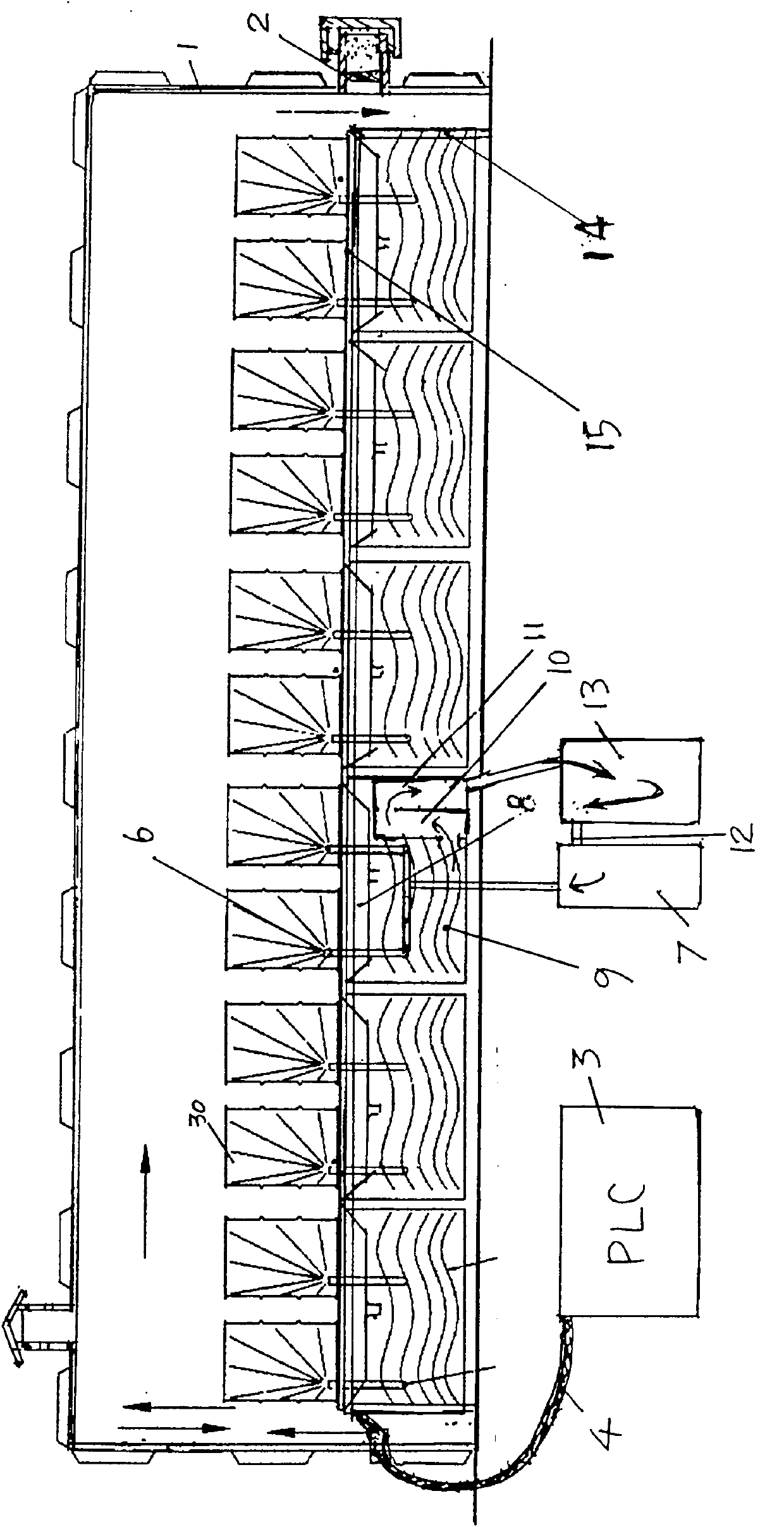

[0017] like figure 1 As shown in the automatic production line for high-purification treatment steel drums, there is a sealed cabin 1 outside the mechanical part of the overall high-purification treatment steel drum automatic production line. Outside the sealed cabin, the PLC automatic control system is connected with the control device execution parts of the mechanical parts in the sealed cabin by the explosion-proof wire 4 .

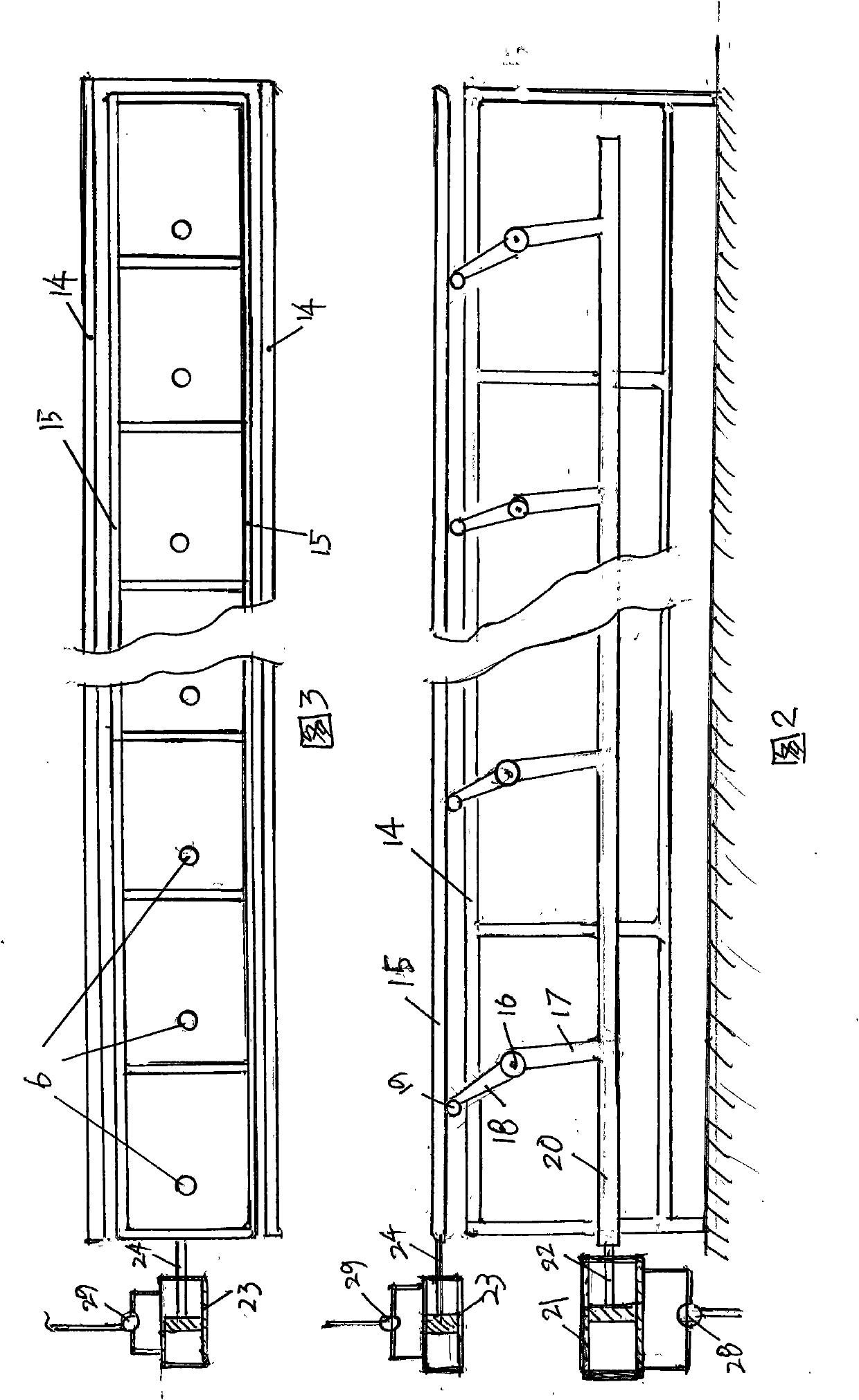

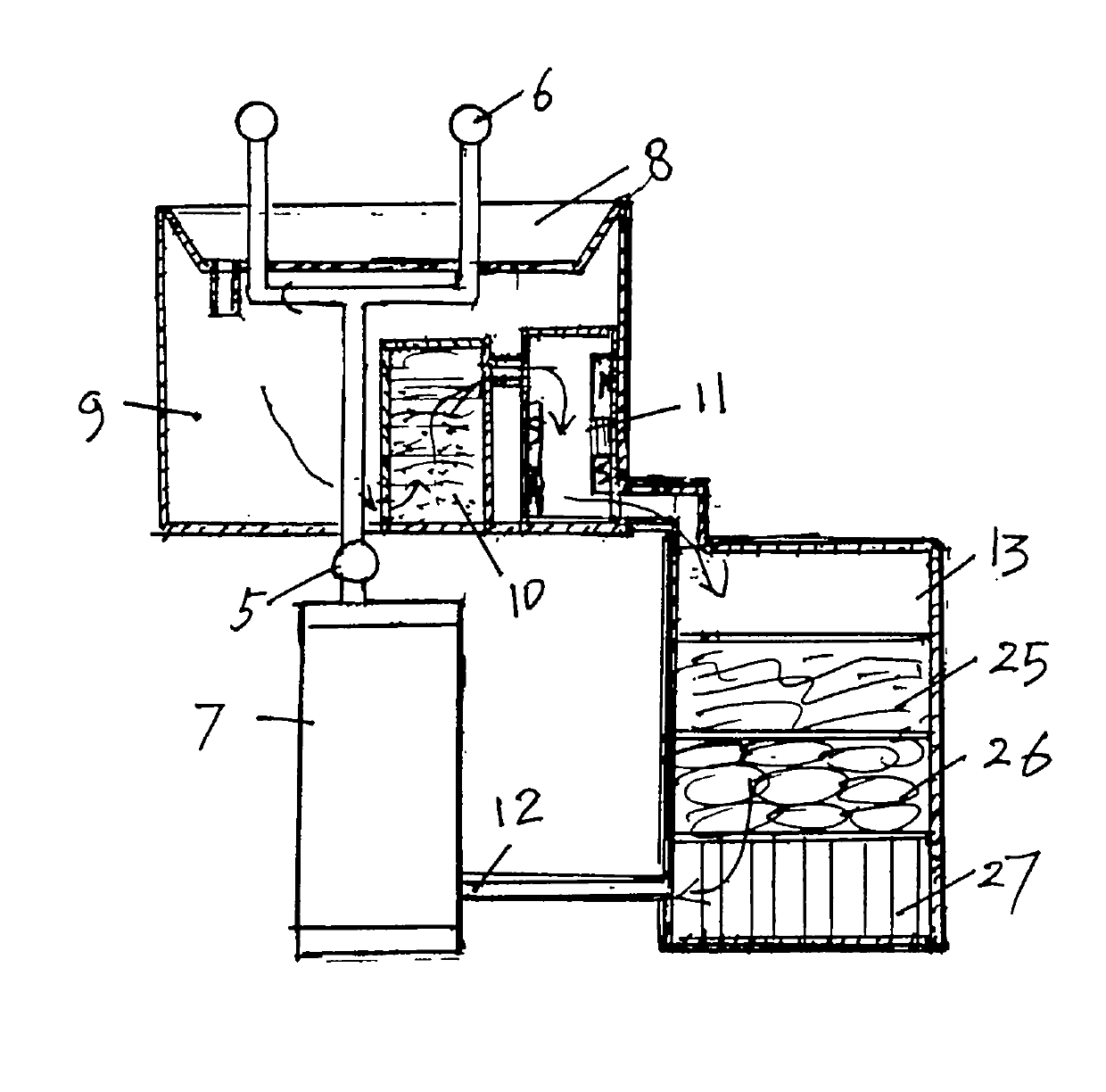

[0018] like figure 1 , 4 The mechanical part of the steel drum high-purification treatment production line shown: there are multiple cleaning stations in succession. The production line has a steel drum transfer device that moves the steel drum 30 along the direction of the working station. In each working station, there are respectively Rotary nozzle 6 cleaning device with control valve 5, each nozzle is connected to the output end of an anti-corrosion type 3-hour diaphragm pump 7; a cleaning liquid collection plate 8 is arranged under the nozzles o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com