Material cleaning device of pipe welder

A technology of cleaning device and pipe welding machine, which is applied to the cleaning method using tools, the cleaning method using liquid, drying machine, etc., which can solve the problems of impracticability, heavy workload, and affecting the quality of welds, so as to avoid fouling , Moderate roughness and clean outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

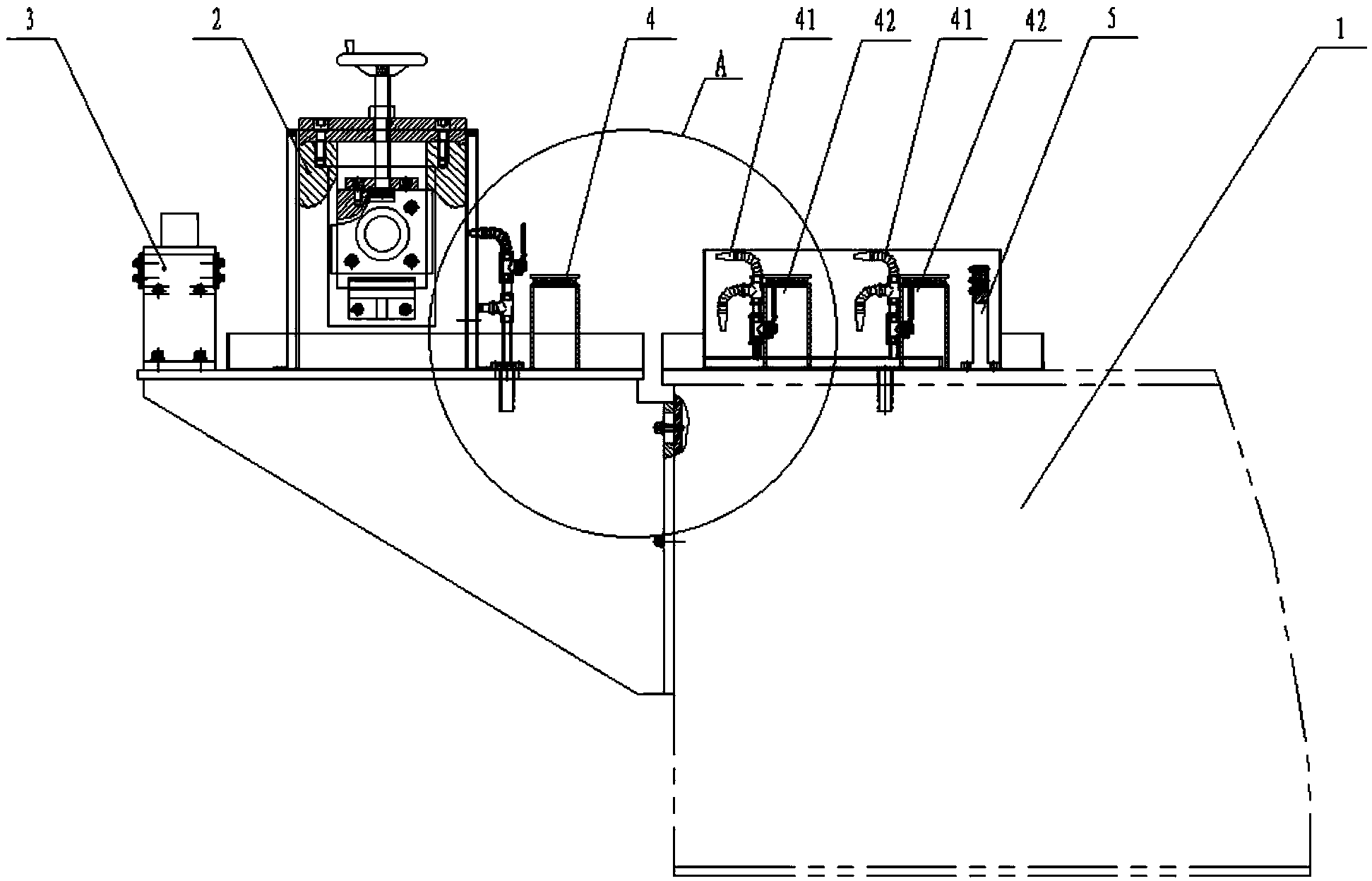

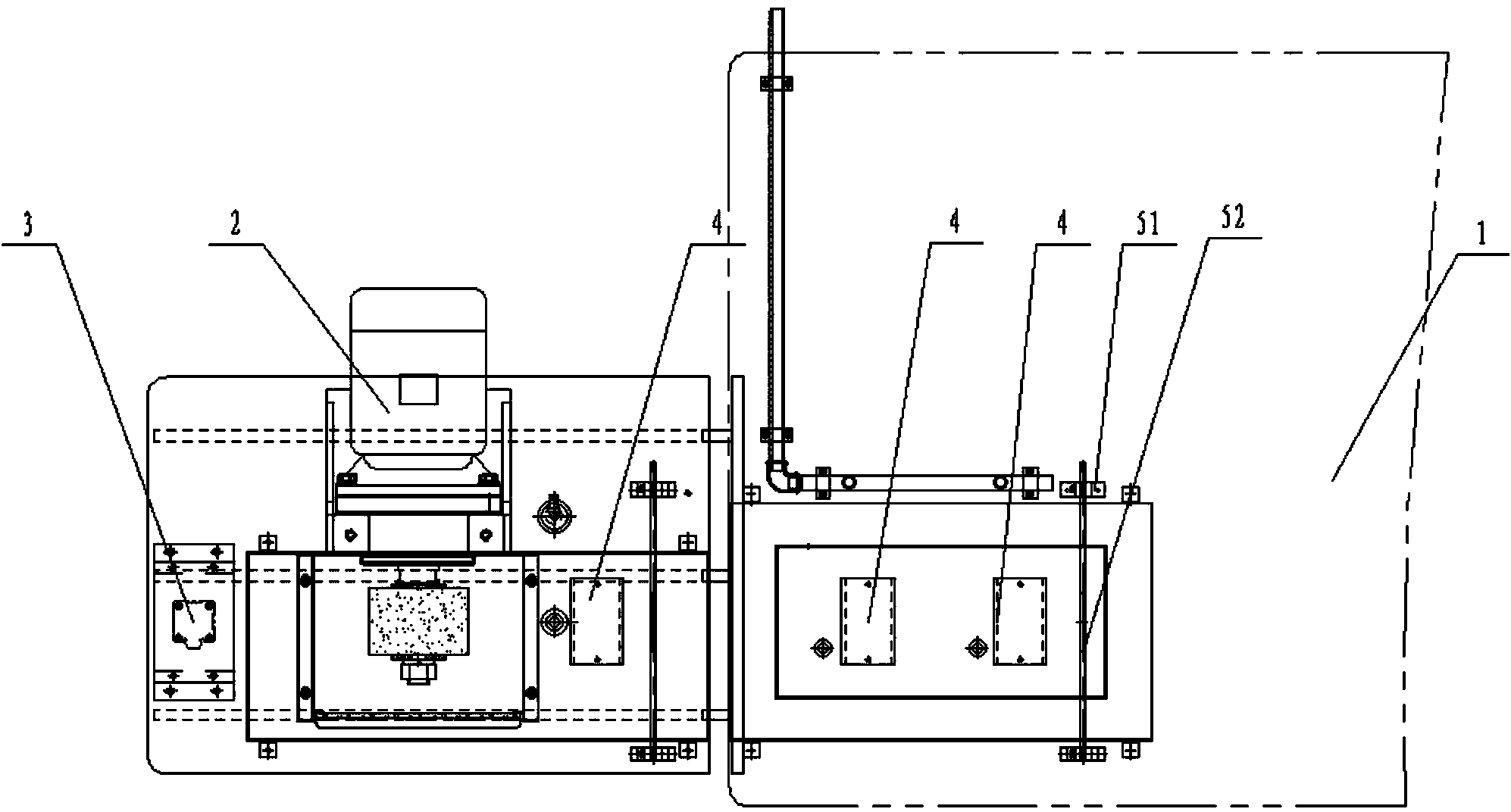

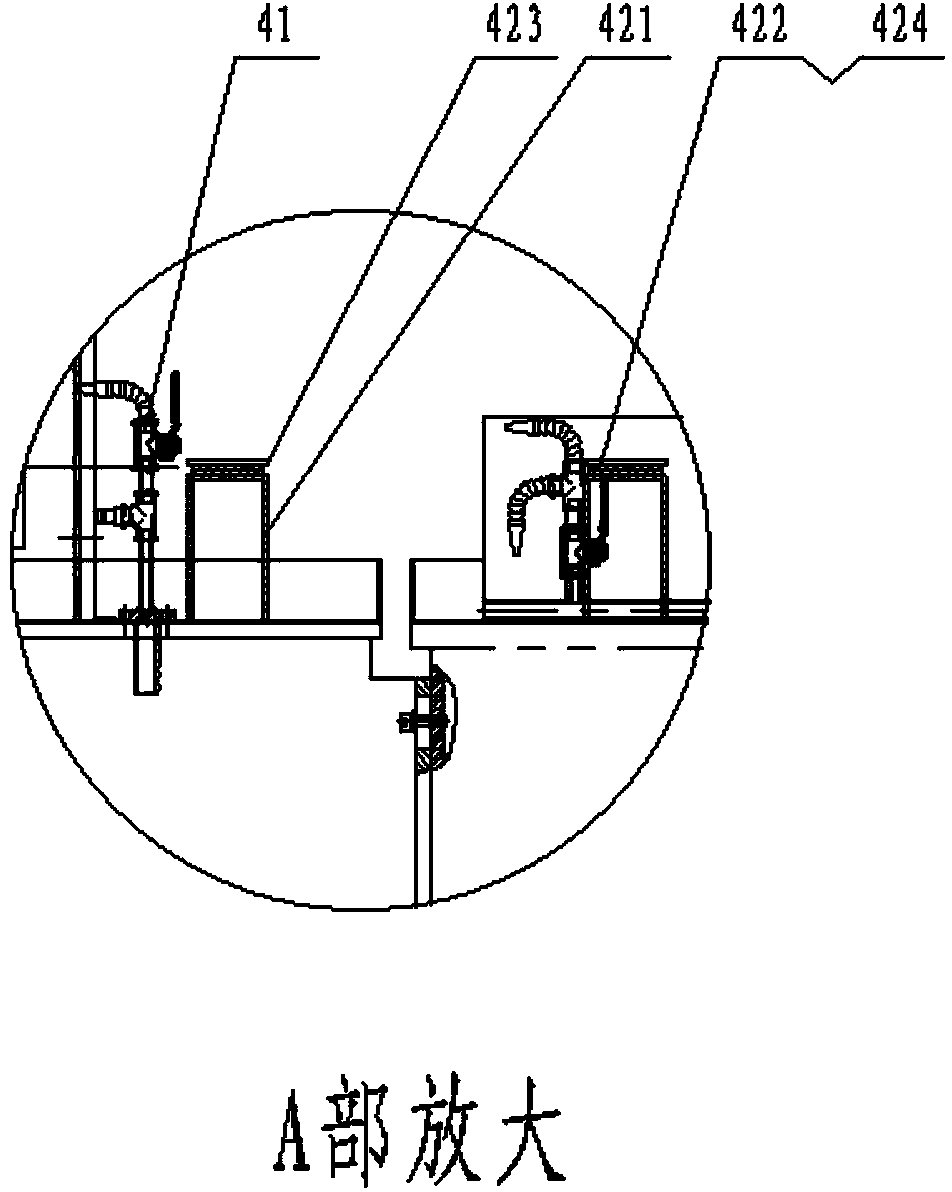

[0021] Such as Figure 1-5 As shown, a raw material cleaning device for a welded pipe machine includes a machine base 1, and the machine base 1 is provided with a cleaning mechanism 3, a grinding and polishing mechanism 2, several washing mechanisms 4 and a hot air drying mechanism 5 in sequence.

[0022] Such as figure 1 , 2 , 4, the cleaning mechanism 3 includes a bottom plate 31 arranged on the machine base 1, two side plates 32 are oppositely arranged on the bottom plate 31, and a cylinder seat 33 is arranged across the top of the two side plates 32, and a cylinder seat 33 is provided on the cylinder seat 33. Compress the cylinder 34 vertically downwards, the end of the cylinder piston rod is provided with a movable plate 35, the lower surface of the movable plate 35 is provided with a wool felt 36, and the two side plates 32 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com