Wafer transmission device, wafer transmission method and CMP equipment cleaning module

A technology of a transmission device and a transmission method, which is applied in the directions of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of wafer cleaning effect, drop, etc., and achieve shortened transmission time, high cleanliness, and reduced handling. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

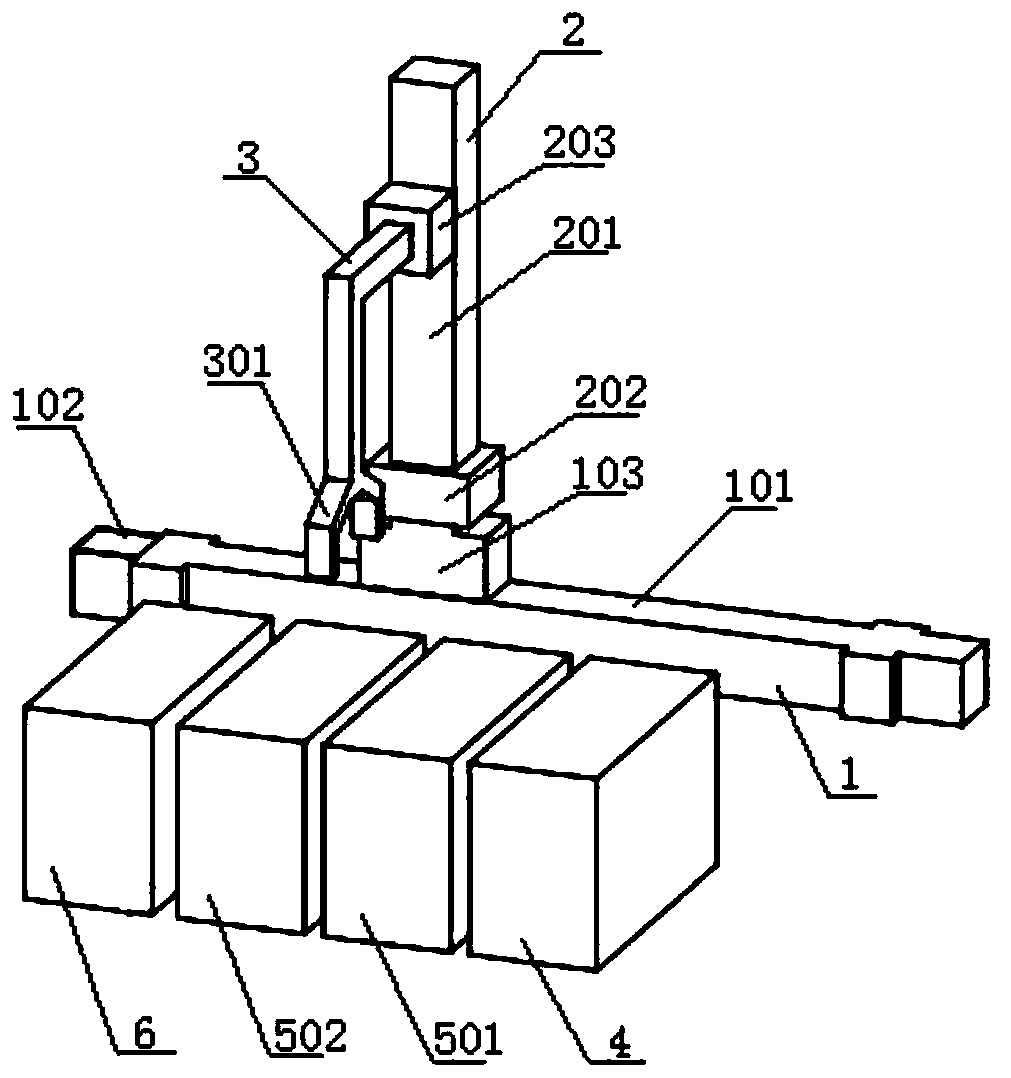

[0046] Such as figure 1 As shown, it is the first embodiment of a cleaning module of CMP equipment provided by the present invention. The wafer transfer device of the cleaning module of CMP equipment includes an X-axis moving module 1, a Z-axis moving module 2 and a clamping jaw Arm module 3; the X-axis moving module 1 is located on one side of the CMP equipment cleaning module, and the X-axis moving module includes an X transmission shaft 101, an X-axis driver 102, and an X-axis moving slider 103; the Z-axis moving Module 2 is fixedly installed on the X-axis moving slider 103, and the Z-axis moving module 2 includes a Z transmission shaft 201, a Z-axis driver 202, and a Z-axis moving slider 203; the jaw clamping arm module 3 is installed On the Z-axis moving slider 203 , the jaw clamping arm module 3 includes a jaw clamping arm 301 , which can rotate around the Z-axis moving slider 203 .

[0047] The wafer transfer method of the wafer transfer device of this embodiment is: ...

Embodiment 2

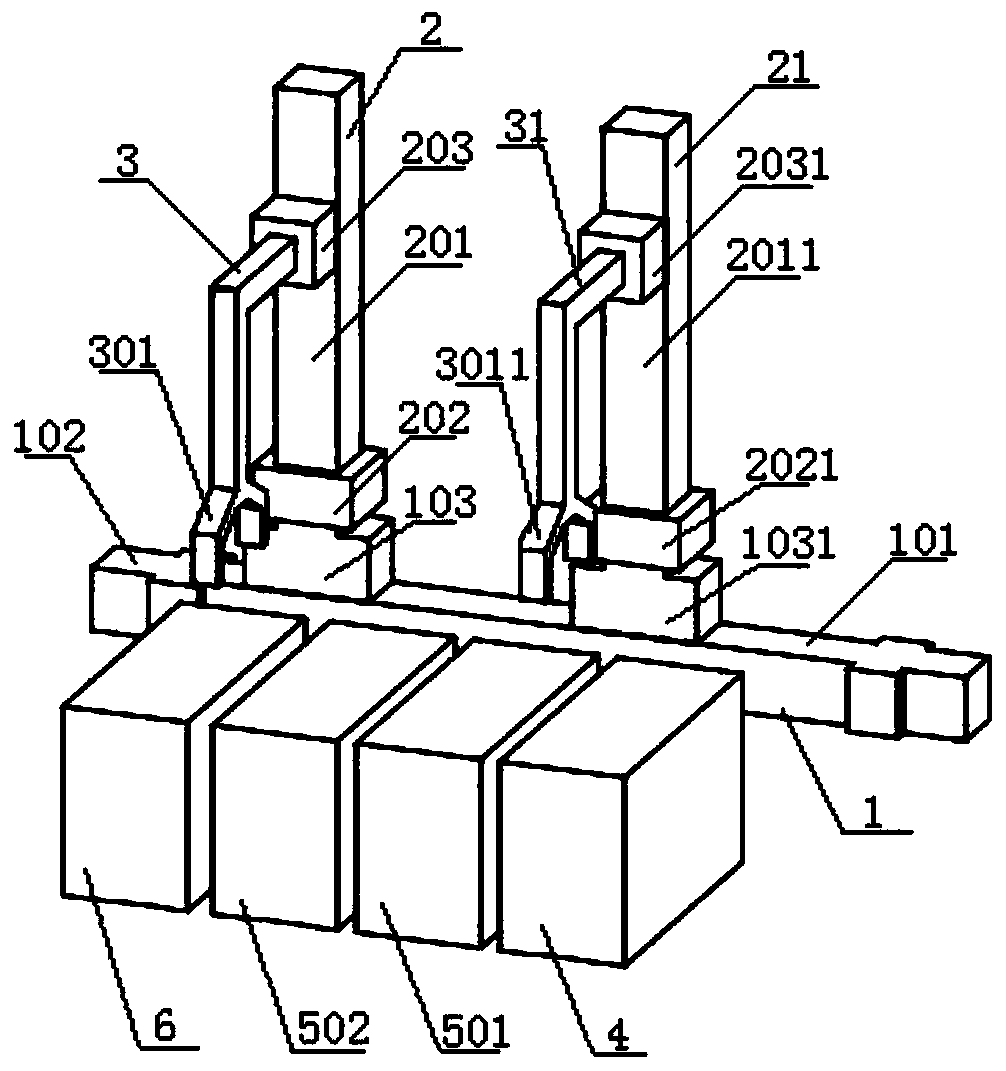

[0050] Such as figure 2 Shown is the second embodiment of a CMP equipment cleaning module provided by the present invention. Compared with the first embodiment, the second embodiment includes a first Z-axis moving module 21 and a first The jaws grip the arm module 31 . The wafer transfer device of the CMP equipment cleaning module provided in this embodiment includes an X-axis moving module 1, a Z-axis moving module 2, a first Z-axis moving module 21, a jaw clamping arm module 3 and a first jaw clamping arm Module 31; the X-axis moving module 1 is located on one side of the CMP equipment cleaning module, and the X-axis moving module includes an X transmission shaft 101, an X-axis driver 102, an X-axis moving slider 103, and a first X-axis moving slider 1031 , the X-axis moving slider 103 and the first X-axis moving slider 1031 move independently on the X transmission shaft 101; the Z-axis moving module 2 is fixedly mounted on the X-axis moving slider 103, and the Z-axis movi...

Embodiment 3

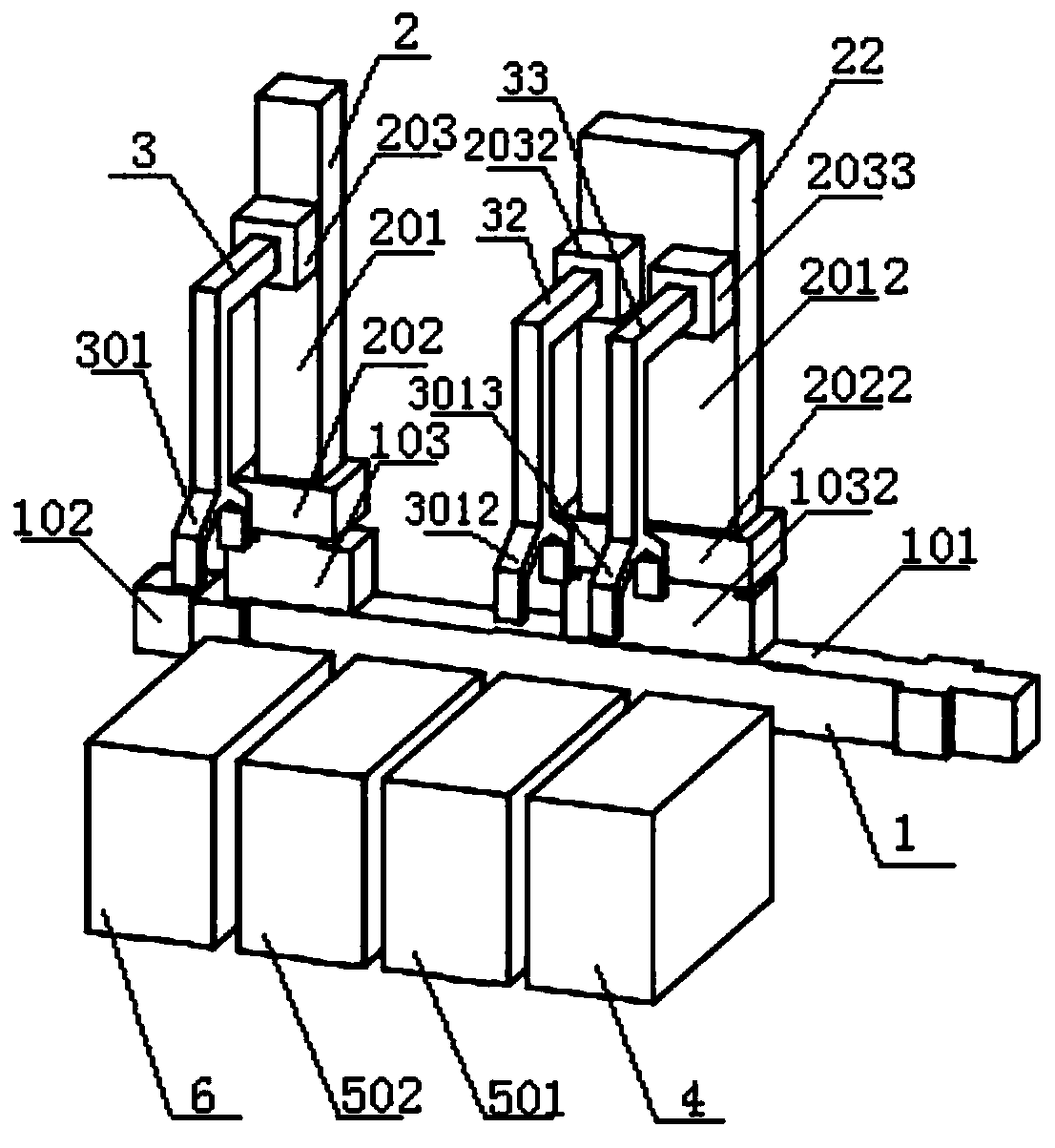

[0054] Such as image 3 Shown is the third embodiment of a CMP equipment cleaning module provided by the present invention. Compared with the first embodiment, the third embodiment includes a second Z-axis moving module 22 and a second A jaw gripping arm module 32 and a third jaw gripping arm module 33 . The wafer transfer device of the CMP equipment cleaning module provided in this embodiment includes an X-axis moving module 1, a Z-axis moving module 2, a second Z-axis moving module 22, a jaw clamping arm module 3 and a second jaw clamping arm Module 32 and the third claw clamping arm module 33; the X-axis moving module 1 is located on one side of the CMP equipment cleaning module, and the X-axis moving module includes an X transmission shaft 101, an X-axis driver 102, and an X-axis moving slider 103. The second X-axis moving slider 1032, the X-axis moving slider 103 and the second X-axis moving slider 1032 move independently on the X transmission axis 101; the Z-axis moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com