Method for detecting fluid flow and fluid heat quantity by thermal flow and its application device

A fluid flow and heat flow detection technology, applied in mass flow measurement devices, heat measurement devices, measurement devices, etc., can solve the problems of no flowmeter, fluid calorimeter, no method for detecting fluid heat, large liquid heat consumption, etc. The effect of low damage possibility, clear detection link and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

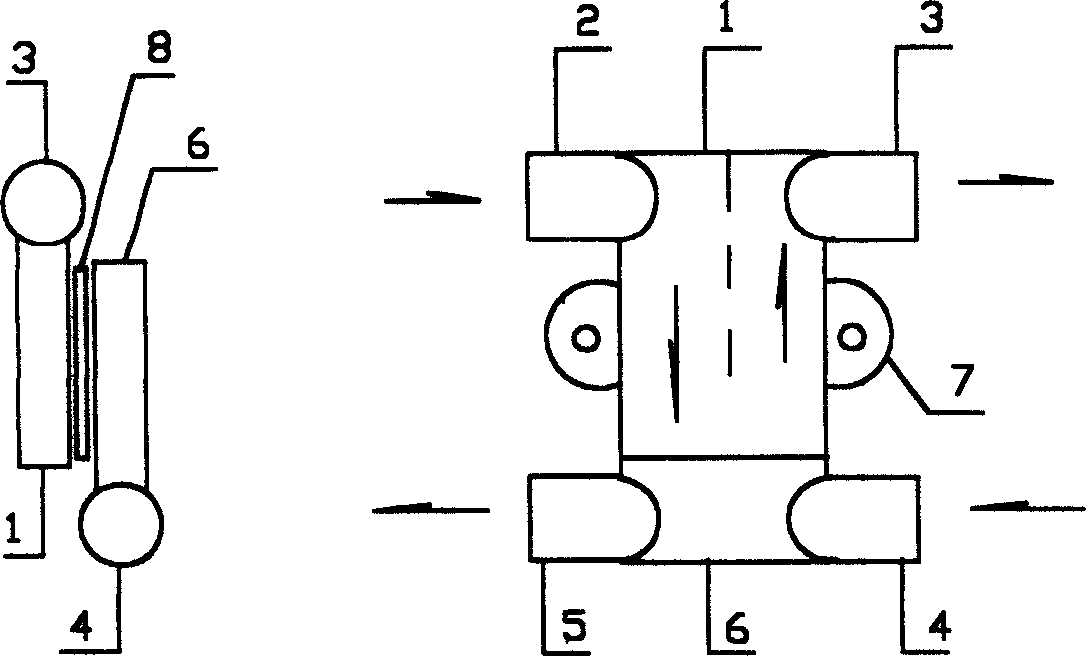

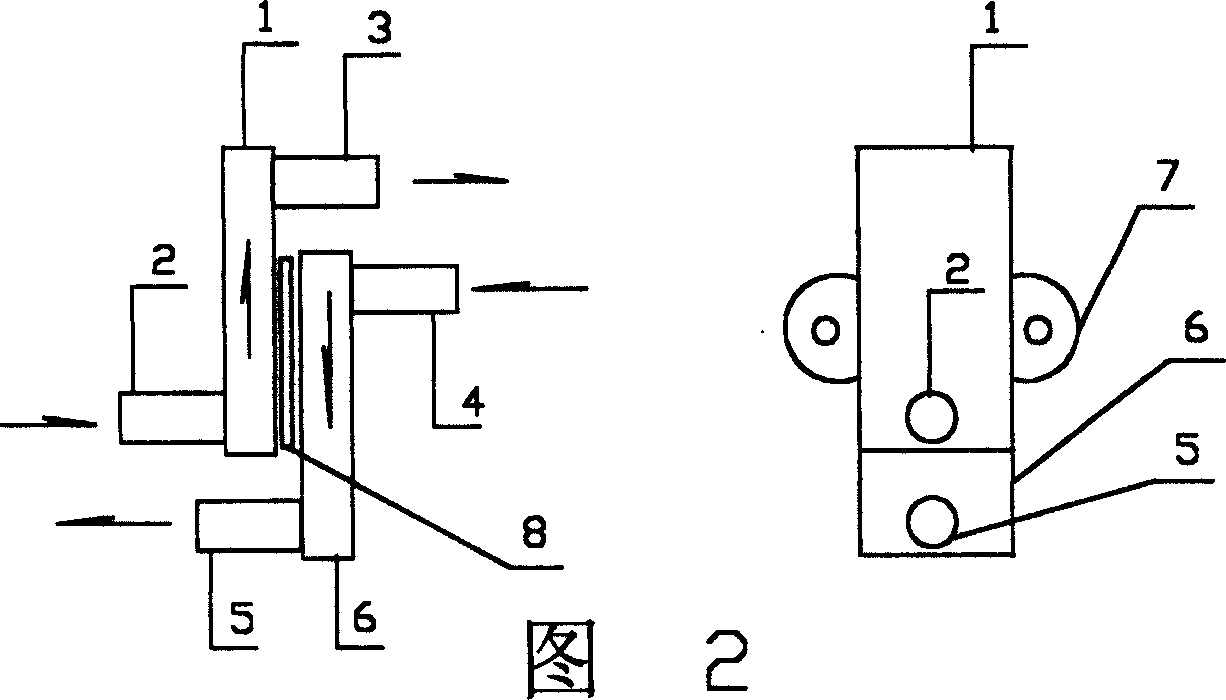

[0017] Mode 1. Method for detecting fluid flow and fluid heat with heat flow—and an application detection device thereof

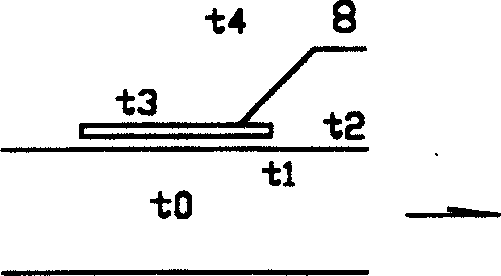

[0018] Detection principle: The heat Q1 transferred from the fluid to the outside of the tube or wall through the tube or wall is composed of three serial processes. First, the convective heat transfer Q1 between the fluid and the inner surface of the tube or wall, and then the heat exchange between the inside and outside of the tube or wall. The conduction heat transfer Q2, and then the heat transfer Q3 between the outside of the tube or wall and the environment. Q3 can be one of conduction heat transfer, convective heat transfer, radiation heat transfer or composite heat transfer depending on the environment outside the tube or wall. Heat; because it is a series heat flow, Q==Q1==Q2==Q3; one of Q, Q1, Q2, Q3 can be detected and four can be determined at the same time.

[0019] According to Newton's formula of convective heat transfer: Q==α*Δt (0-3a formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com