Continuous production device of plastic coated stainless steel pipeline

A technology for production equipment and stainless steel pipes, applied in welding equipment, heat treatment equipment, metal processing equipment, etc., can solve the problems of difficult to guarantee the internal cleanliness of pipes, low efficiency, plastic waste, etc., to achieve low cost, high production efficiency, avoidance of fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

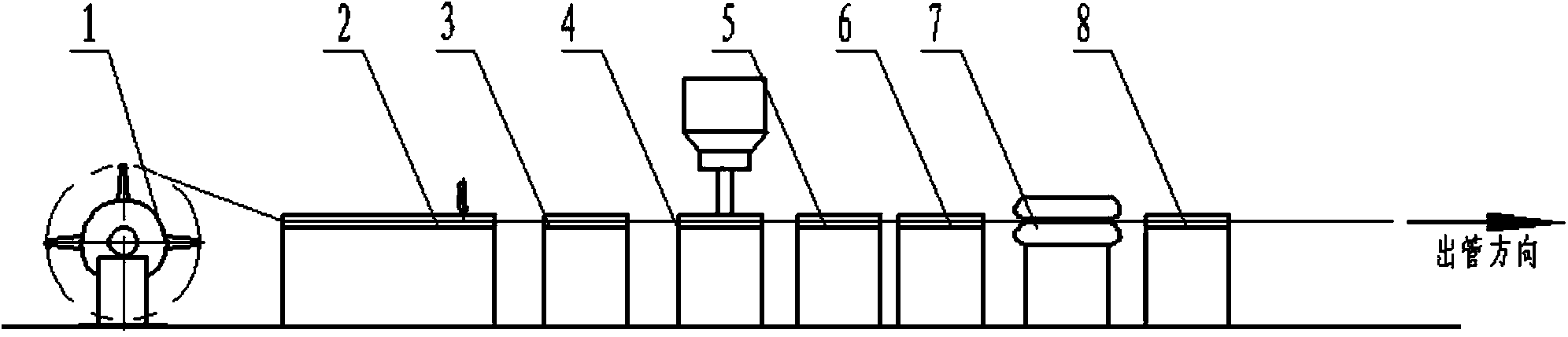

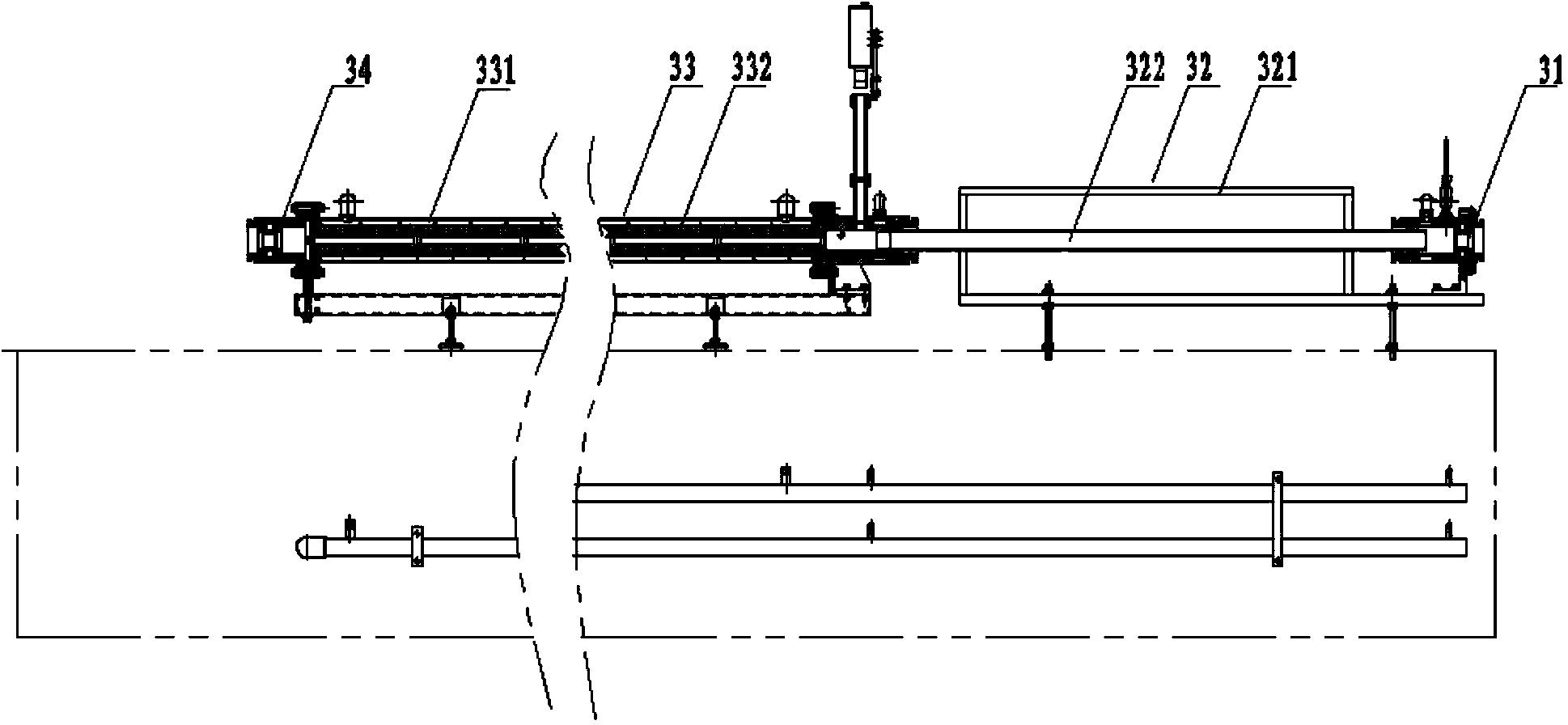

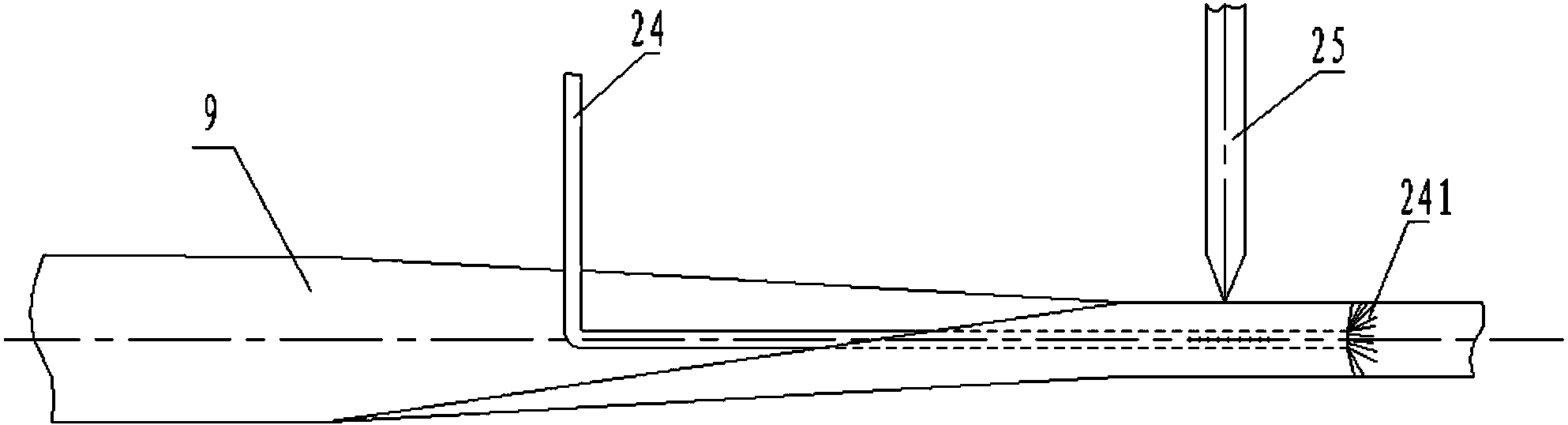

[0028] Such as Figure 1-4 As shown, a production equipment for plastic-coated stainless steel pipes includes a stainless steel strip unwinding machine 1, a welded pipe machine 2, a weld seam solution tempering device 3, a plastic-coated extruder 4, a composite pipe sizing device 5, and a cooling device 6. Caterpillar tractor 7 and cutting machine 8. The welded pipe machine 2 is provided with a strip cleaning and decontamination device 22 , a grinding and polishing mechanism 21 and several flushing mechanisms 23 in sequence on the machine base at the feed end. The pipe welding machine 2 is also provided with a gas supply pipe 24 for outputting inert gas. The gas supply pipe 24 extends from the unrolled part of the stainless steel strip 9 to the curled welding position. The end of the gas supply pipe 24 is provided with a wire brush 241.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com