Copper-aluminium combined pipeline piece with identical joint diameter and aluminium pipe

A joint pipe and composite pipe technology, which is applied in the field of copper-aluminum composite pipe fittings, can solve problems such as the influence of cooling effect, the inability to expand pipe processing, and the limitation of the application range of copper-aluminum composite pipe fittings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

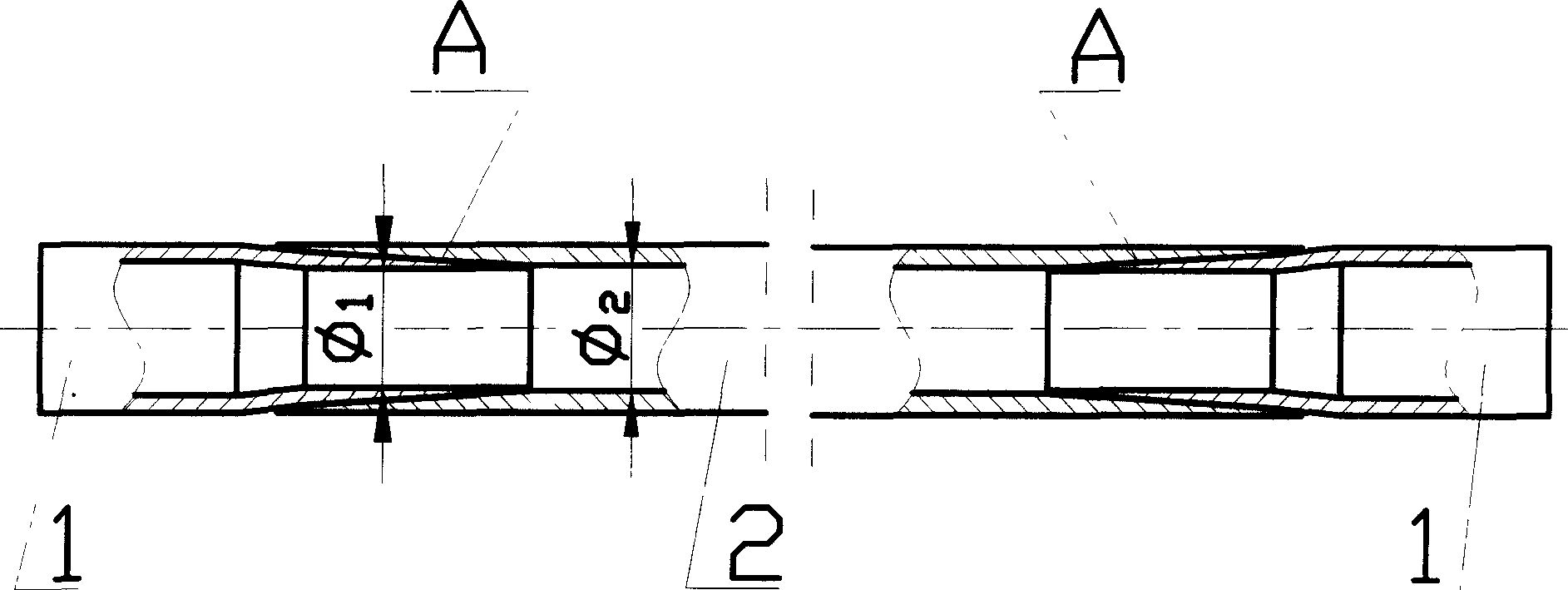

[0010] like figure 1 In the present invention, a section of copper tube 1 is welded at one or both ends of the aluminum tube 2, and the bonding surface of the copper tube 1 and the aluminum tube 2 with the same or similar outer diameter is tapered with the copper tube inside and the aluminum tube outside. Socket surface A, the inner diameter φ1 of the pipeline of the welded joint formed by the tapered socket surface A is equal to or close to the inner diameter φ2 of the aluminum tube 2 .

[0011] The processing step is to firstly process the welding part of the copper pipe end into a straight pipe with a thin wall, and then weld the socketed copper pipe and aluminum pipe firmly by a pressure welding machine to form a welded copper-aluminum composite pipe fitting. joint, and then expand the reduced-diameter straight tubular copper tube inside the welded joint to form an inner diameter at the joint that is equal to or close to the inner diameter of the aluminum tube. As mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com