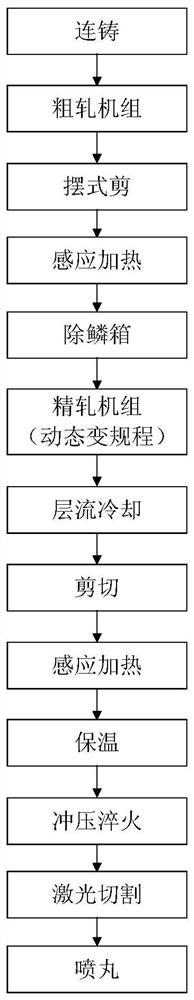

Plate blank performance gradient distribution forming method based on ESP dynamic variable regulation

A technology of gradient distribution and changing rules, applied in furnace types, furnaces, quenching devices, etc., can solve problems affecting the production efficiency of enterprises, shorten the process flow, speed up the production rhythm, etc., to promote high-quality development, release process potential, improve The effect of enterprise production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

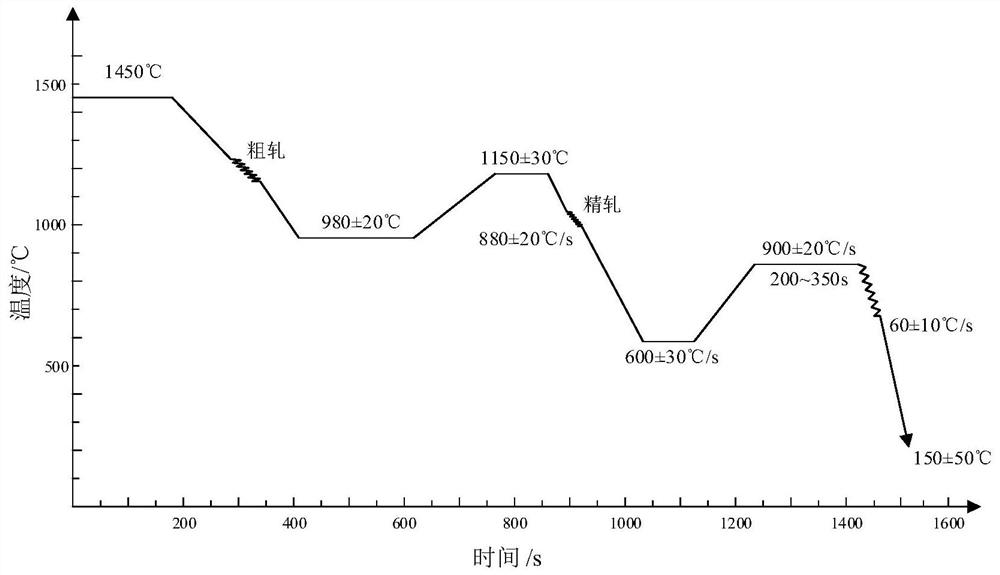

[0041] In the rolling process of this embodiment, the temperature of the thin slab after continuous casting is 1450°C, and then after the rough rolling treatment of the rough rolling unit, the temperature drops to 960°C, and the temperature is raised to 1120°C after the induction heating treatment, and then passes through the finishing rolling unit After finish rolling, the temperature drops to 860°C, and after laminar cooling, the temperature drops to 570°C.

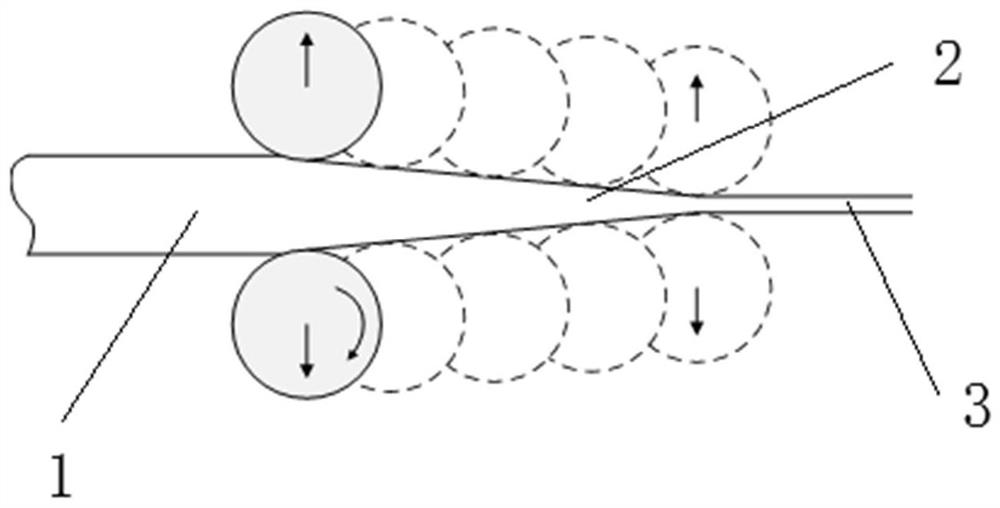

[0042] When the rolls of one of the five-stand rolling mills are severely worn under working conditions, the "5+1" dynamic schedule change strategy is activated, the standby rolling mill is pressed down and put into work, and the rolls of the worn rolling mill are lifted up to exit rolling production, realizing online non-stop Shut down to change rolls, and the last rolling mill uses roll gap adjustment technology to continuously change the geometric shape of the rolled piece along the rolling direction to produce variab...

Embodiment 2

[0047] In this example, during the rolling process, the temperature of the thin slab after continuous casting is 1450°C, and after rough rolling by the rough rolling mill, the temperature drops to 980°C, and the temperature is raised to 1150°C by induction heating, and then passes through the finishing mill After finish rolling, the temperature drops to 880°C, and after laminar cooling, the temperature drops to 600°C.

[0048] When the rolls of one of the five-stand rolling mills in the working state are severely worn, the "5+1" dynamic schedule change strategy is activated, the standby rolling mill is pressed down and put into work, and the rolls are worn out, and the rolls of the rolling mill are lifted up to exit rolling production, realizing online roll change without stopping the machine. The last rolling mill uses roll gap adjustment technology to continuously change the geometric shape of the rolled piece along the rolling direction to produce variable-thickness slabs. ...

Embodiment 3

[0053] In this example, during the rolling process, the temperature of the thin slab after continuous casting is 1450°C, and after rough rolling by the rough rolling unit, the temperature drops to 1000°C, and the temperature is raised to 1180°C by induction heating, and then passes through the finish rolling unit After finish rolling, the temperature drops to 900°C, and after laminar cooling, the temperature drops to 630°C.

[0054] When the rolls of one of the five-stand rolling mills in the working state are severely worn, the "5+1" dynamic schedule change strategy is activated, the standby rolling mill is pressed down and put into work, and the rolls are worn out, and the rolls of the rolling mill are lifted up to exit rolling production, realizing online roll change without stopping the machine. The last rolling mill uses roll gap adjustment technology to continuously change the geometric shape of the rolled piece along the rolling direction to produce variable-thickness sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com