Production process for screen printed circuit board

A technology of screen printing and production process, applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problems of low production efficiency, production cost can not be further reduced, silver paste blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A production process of screen printed circuit boards, comprising the following steps: substrate cutting - edge grinding - NC drilling - deburring - graphic pretreatment - surface B screen printing graphic photocurable resist ink - UV light Curing—A side screen printing graphic photocurable resist ink—UV curing—etching, film removal—pretreatment for solder mask printing—A side screen printing photocurable solder resist ink—UV curing—B side screen printing photocurable resist Soldering ink—UV curing—silver paste / copper paste through hole printing pretreatment—silver paste / copper paste through hole screen printing—silver paste / copper paste hot air pre-drying, drying—preprinting treatment—A\B side silver paste / Copper paste protective layer printing and UV curing—A\S surface text printing machine curing—subsequent production process.

Embodiment 2

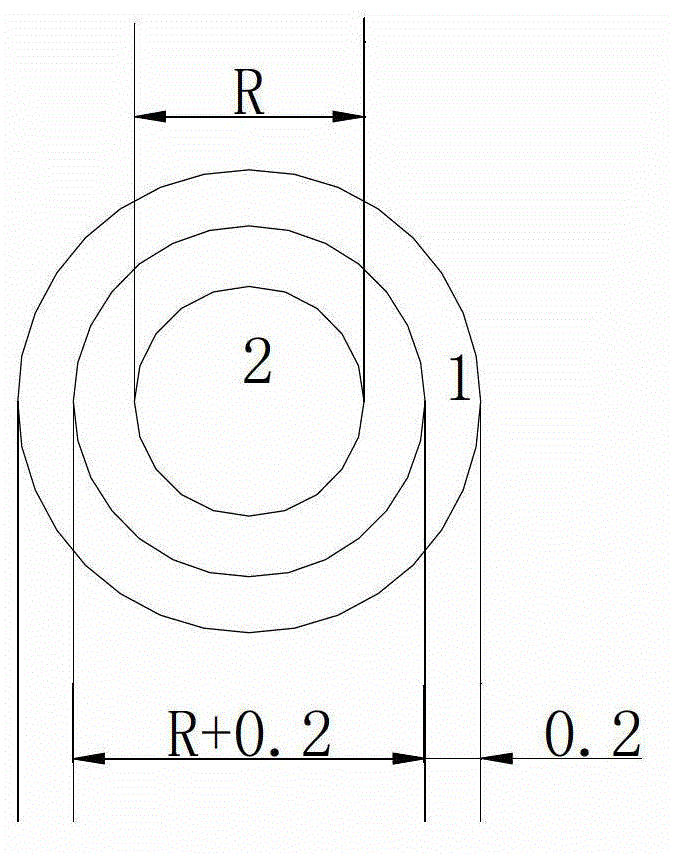

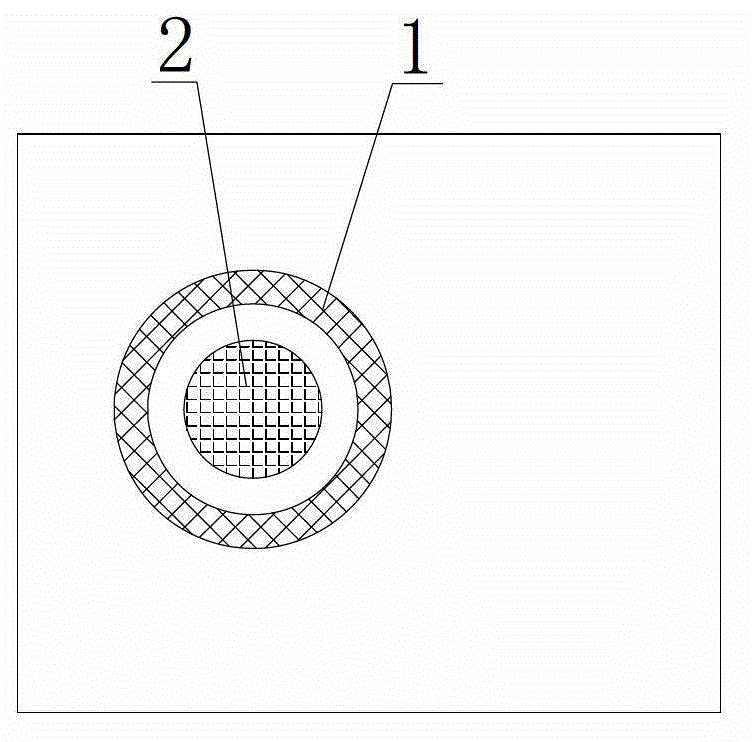

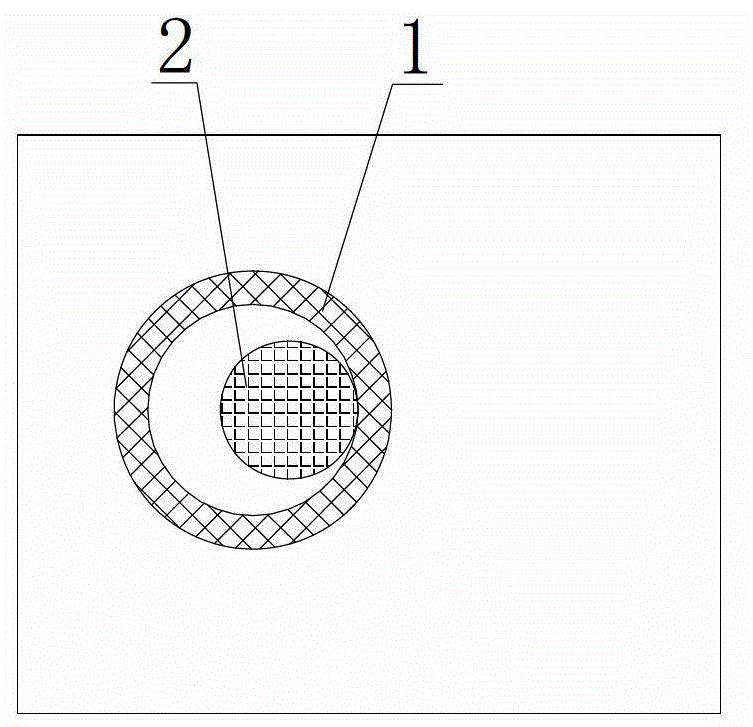

[0021] Embodiment 2: refer to Figure 1~4 . When the substrate is subjected to the NC drilling process step, the printing positioning hole and the punching positioning hole are drilled at one time as the reference hole 2 for graphic printing matching, and the diameter of the reference hole 2 is R; Make a ring pattern matching the reference hole 2 on the photo of the net making, that is, the pattern line 1, the ring width is 0.2mm, and the diameter of the inner ring is the reference hole diameter R+0.2mm, and the screen printing pattern light on the B side is printed by screen printing. Curing the anti-corrosion ink, checking the matching and coincidence degree of the graphic circuit 1 and the reference hole 2, that is, judging whether the matching accuracy of the graphic circuit 1 and the reference hole 2 meets the requirements with the naked eye; after printing and curing the graphic on the B side, carry out the graphic printing on the A side , the same as the above printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com