Process for simultaneously producing machine coke and molded coke by use of stamp-charging coke oven

A technology for tamping coke ovens and mechanical cokes, which is applied in coke ovens, petroleum industry, special forms of carbonization, etc., can solve the problems of large demand for molded coke and unsatisfactory production capacity of inclined bottom furnaces, etc., to increase product types, solve Difficult to push focus and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] as attached figure 1 and 2 Shown, a kind of technology that adopts tamping coke oven to produce mechanical coke and form coke at the same time, process steps are as follows:

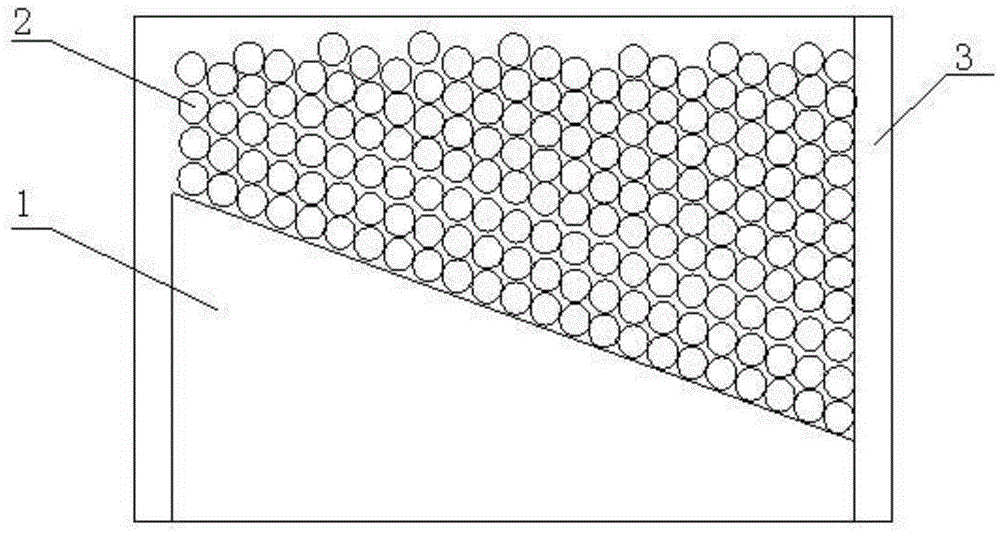

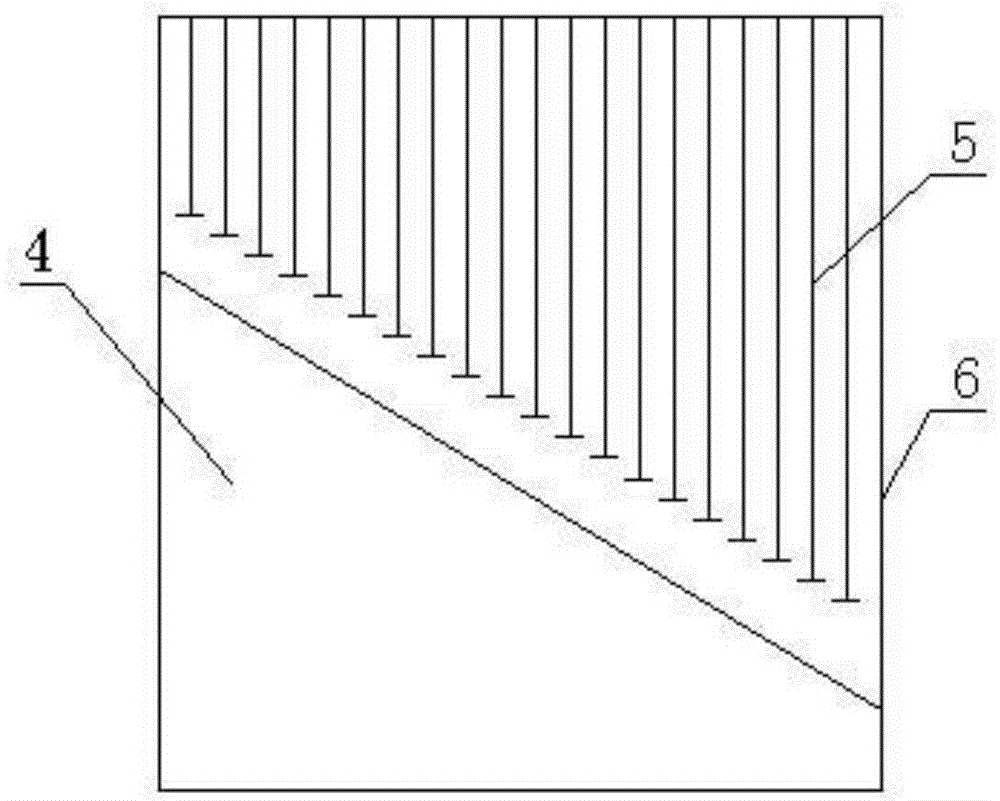

[0020] In the coal loading car 6, the loaded coal mix 4 is tamped by the tamping hammer 5 along the vertical direction, and the length of the tamping hammer 5 in the tamping direction is a straight line or an arc along the horizontal direction increase. Along the direction that the length of the tamping hammer 5 increases, the amount of blended coal 4 added in the coal loading car 6 is linearly or arc-linearly reduced with the same gradient (as attached figure 2 ), add the blending coal 4 layer by layer, tamp layer by layer, and finally obtain the blending coal briquette 1 (as attached figure 1 ); preferably in the present invention, the length of the tamping hammer 5 in the tamping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com