Variable printer

A printing press, variable technology, applied in printing presses, rotary presses, printing and other directions, can solve the problems of short printing action time, slowing down printing speed, decreased production efficiency, etc., to shorten the replacement time and expand the product range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred Mode for Carrying Out the Invention

[0042] (Outline of variable printing press)

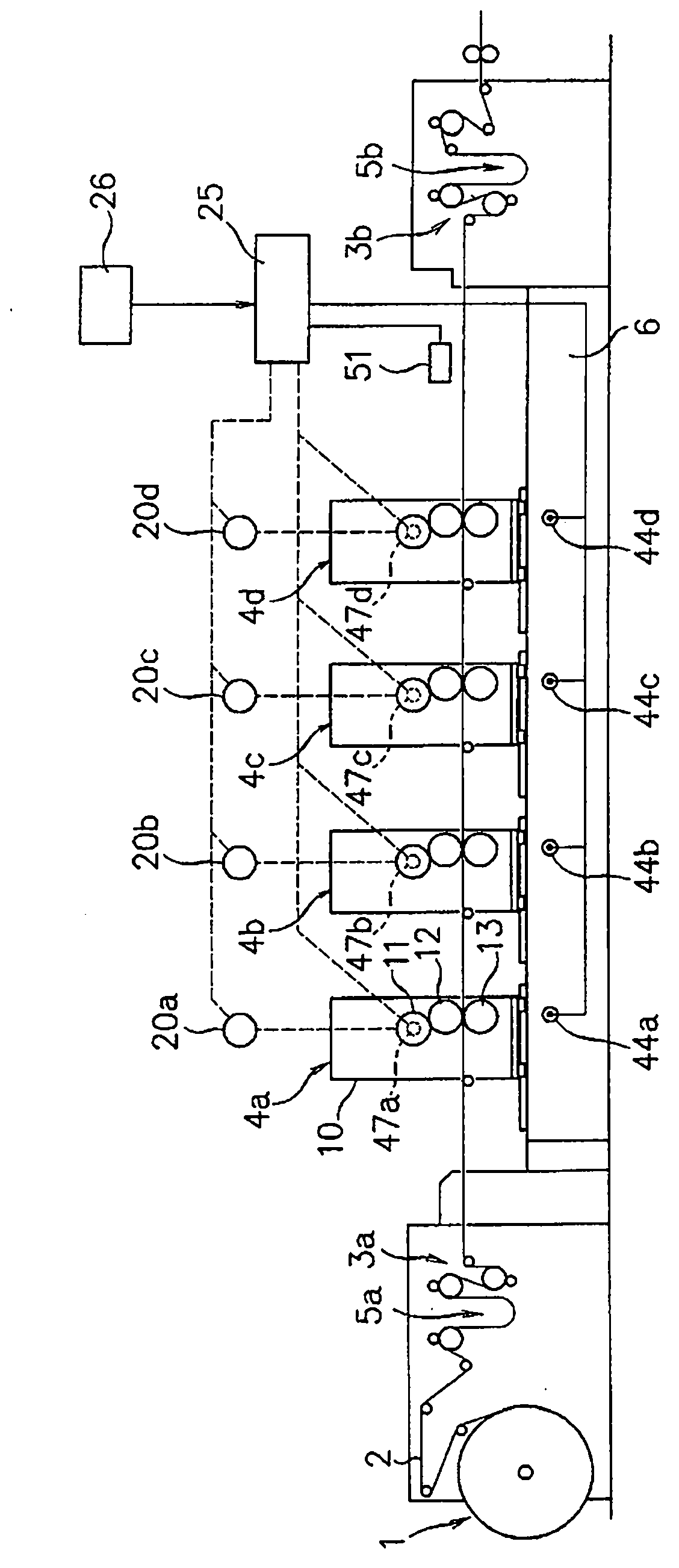

[0043] Such as figure 1 As shown, the paper (rolled paper) 2 supplied from the paper supply unit 1 is conveyed forward and backward by synchronously rotating the intermittent conveying device 3 a on the upstream side and the intermittent conveying device 3 b on the downstream side in forward and reverse directions. Reverse conveying, on the paper traveling line between the intermittent conveying device 3a on the upstream side and the intermittent conveying device 3b on the downstream side, a plurality of printing units are arranged at intervals in the paper traveling direction, such as the first, the second Two, third and fourth printing units 4a, 4b, 4c, 4d.

[0044] Further, ring portions 5a, 5b for absorbing slack in the intermittently conveyed paper 2 are respectively provided upstream of the upstream intermittent conveyance device 3a and downstream of the downstream inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com