Method for manufacturing parquet decorative wood veneers

A wood veneer and wood square technology, which is applied in the direction of wood veneer joining, wood compression, wood treatment, etc., to achieve the effect of protecting and saving precious tree species resources, simplifying the process, and improving the utilization rate of wood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

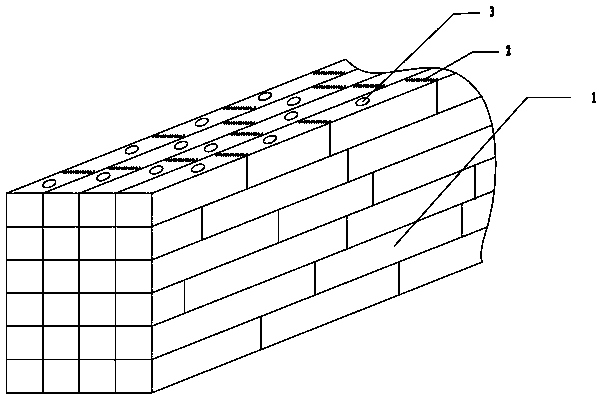

[0027] In this example, the production method of small-diameter wood laminated wood for making parquet decorative wood veneers is as follows:

[0028] 1) Log sawing: After the log is subjected to defect removal treatment, it is sawed into a board with a length of 200mm, a width of 20mm, and a thickness of 10mm;

[0029] 2) Manufacture of long strips of wood: Milling the processed wood planks in the length direction, with the tooth profile on the thickness surface, and then gluing and assembling the billets, and lengthening them longitudinally to make long strips of wood;

[0030] 3) Perforated studs: Randomly drill several five-pointed star-shaped through holes in the thickness direction of the long wood section, and insert viscose studs; the studs are dyed with golden yellow dye (put the studs into the pressure tank Add dyeing agent Acid Bright Yellow G and surfactant diquaternary ammonium salt, and use the method of pressurized impregnation for dyeing treatment, the pressure...

Embodiment 2

[0039]The difference between the production process of the small-diameter wood-glulam planed veneer in this example and Example 1 is: the small-diameter wood after the removal of defects is sawed into wooden strips with specifications of 600mm long, 60mm wide, and 40mm thick, and the wooden strips are made into wide strips. After the width of the plank, holes are drilled in the thickness direction to insert columns. The columns are black and white wooden columns simulating the pattern of Taiji Yin and Yang. After the columns are embedded, they are pressurized and impregnated to make a wet wood square with a size of 3300mm×460mm×460mm, and the rest are the same 1. The final product is a decorative panel embedded with Tai Chi Yin Yang patterns.

[0040]

Embodiment 3

[0042] The difference between the production process of the small-diameter wood-glulam planed veneer and Example 1 is that the defect is eliminated, and the small-diameter wood is sawed into wooden square strips with specifications of 900mm long, 80mm wide and 60mm thick to make wide planks. , and directly make a wooden square with a specification of 2200mm×320mm×320mm, then drill holes, and embed the dyed hollow round columns, and the rest are the same as Example 1. The final product is a decorative panel embedded with a hollow circle pattern.

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com