Dry-mixed mortar production method and production line

A technology of dry powder mortar and production method, which is applied in the direction of chemical instruments and methods, mixing plants, clay preparation equipment, etc., which can solve problems such as high energy consumption, natural sand consumption, and environmental impact, so as to reduce costs and energy consumption, and increase products Effects of type and dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

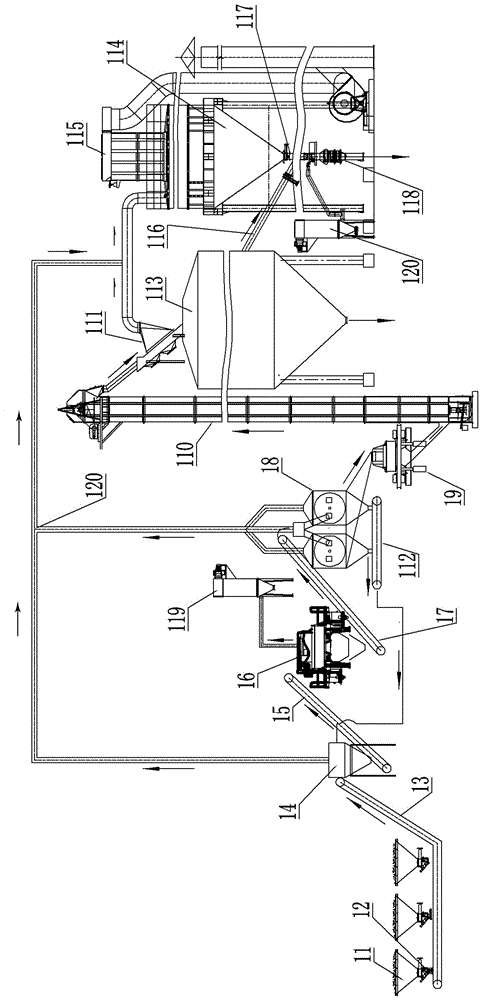

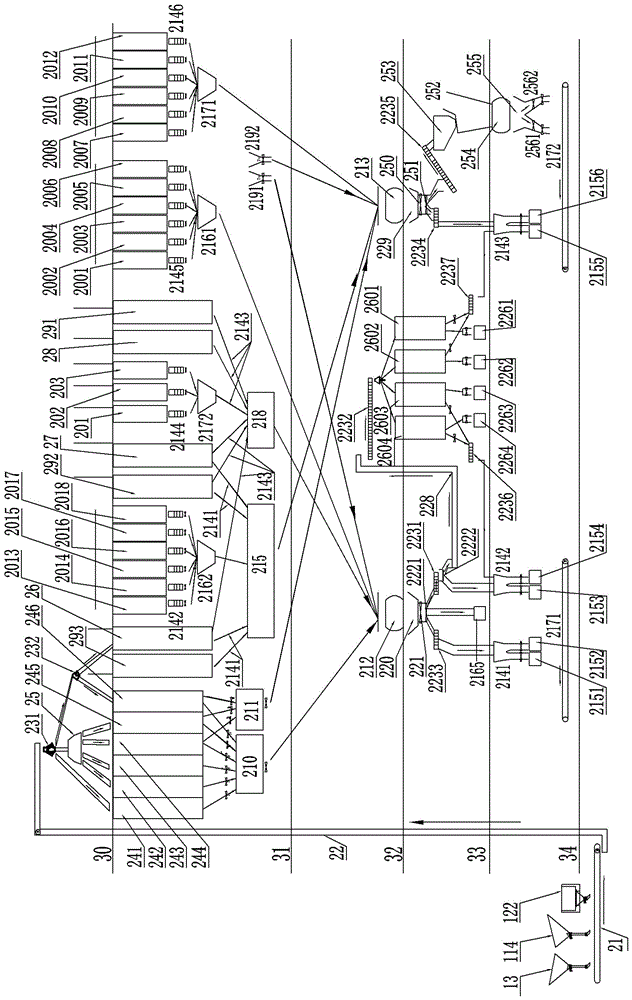

[0031] The embodiment of dry powder mortar production line among the present invention: as figure 1 and figure 2As shown, the dry powder mortar production line is a multifunctional and environmentally friendly dry powder mortar production line device used by concrete manufacturers for the production of dry powder mortar, which can be divided into two parts. A part of the device is a preparation device, and the function of the preparation device is to prepare machine-made powder and machine-made sand material with stone materials. The other part of the device is the production device. The function of the production device is to mix and mix various raw materials to produce dry powder mortar. The discharge port of the preparation device is connected with the feed port of the production device.

[0032] Such as figure 1 As shown, the preparation device includes a raw material bin 11, a pneumatic arc door 12, a first conveyor 13, an intermediate bin 14, a second conveyor 15, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com