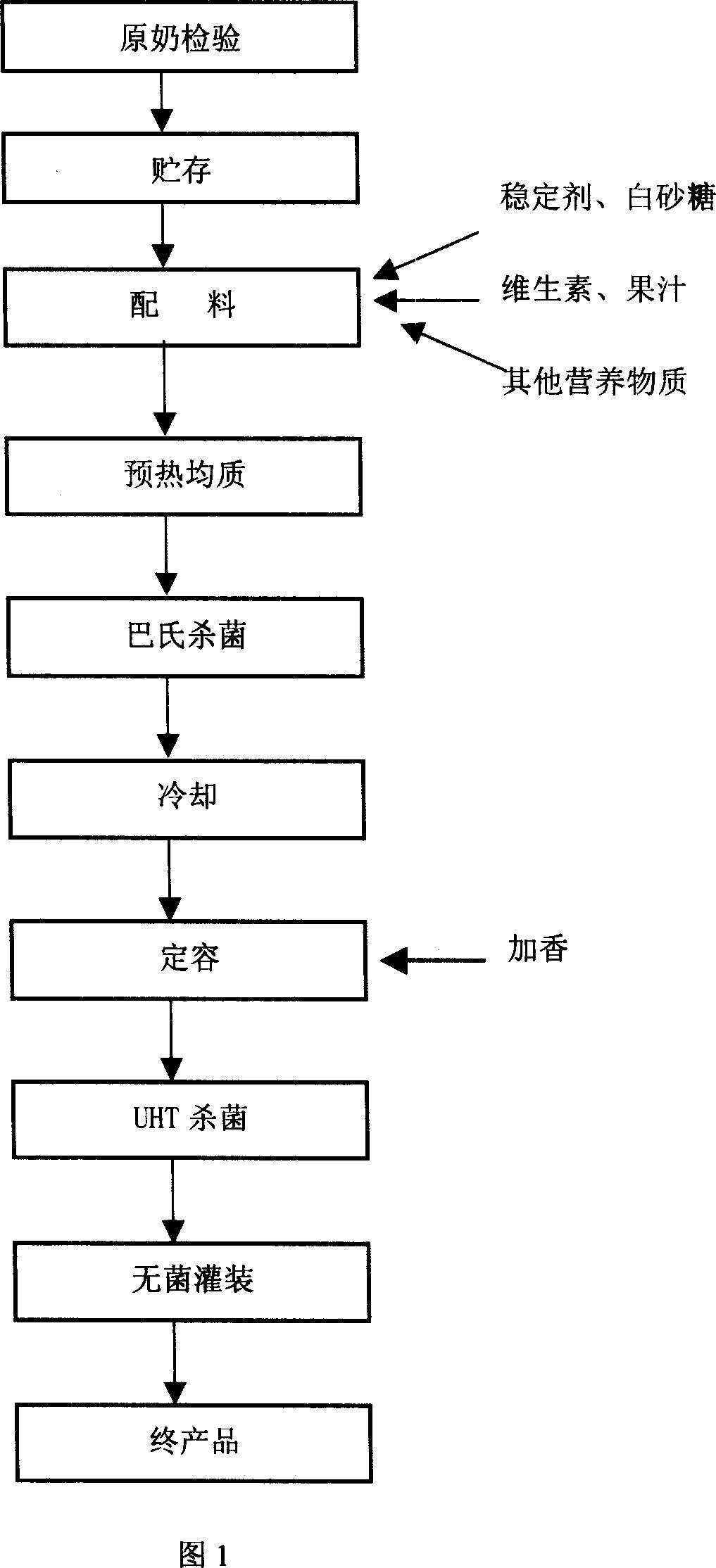

Method for producing air-containing acidic milk-like beverage

A sour milk and beverage technology, applied in dairy products, food preparation, food science, etc., can solve the problems of incapable carbonation of dairy products, increase product taste and flavor, and impossibility of filling, so as to enrich consumer demand and reduce The probability of microbial contamination and the effect of expanding the variety of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the preparation of the gas-filled milk-containing beverage containing orange juice

[0043] Formula (according to 1 ton):

[0044] Milk: 300.0 kg, orange juice: 100.0 kg, white sugar: 55.0 kg, sodium carboxymethylcellulose 2.5 kg, citric acid: 2.5 kg, lactic acid 1.5 kg, orange essence 0.3 kg, carbon dioxide 3.0 kg, purified water 475.2 kg.

[0045] Raw material standard:

[0046] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0047] White sugar: in line with the national first-class standard GB317-2006.

[0048] Orange juice: in line with the relevant national standards GB / T16771-1997.

[0049] Purified water, lactic acid, citric acid: comply with national standards GB17323-1998, GB2023-2003, GB / T8269-1998.

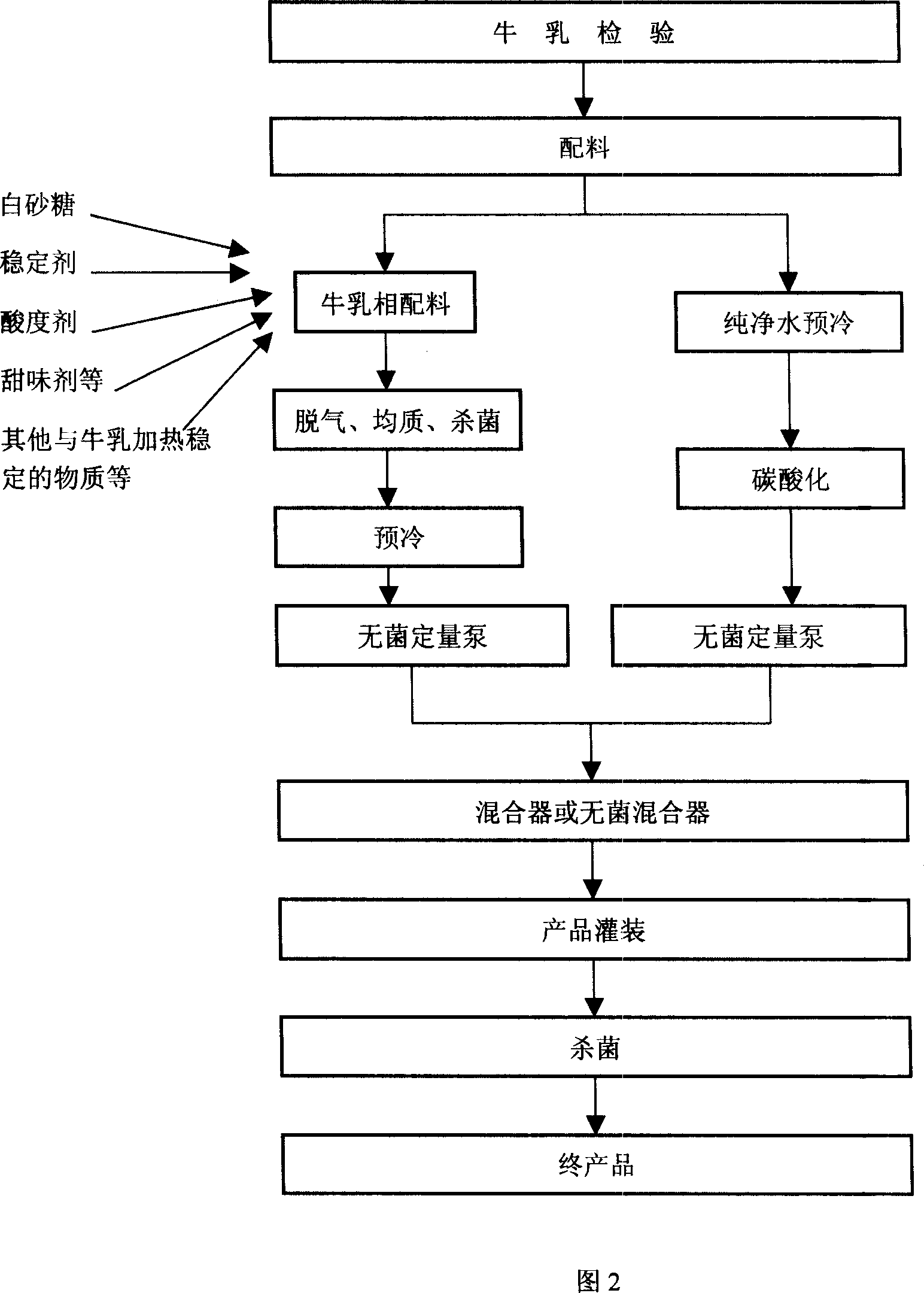

[0050] The preparation process is shown in Figure 2, and the specific process is as follows:

[0051] 1. Inspection of milk

[0052]a. Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids...

Embodiment 2

[0068] Embodiment 2, produce the aerated sour milk drink of green tea taste

[0069] 400.0 kg of milk, 20.0 kg of white sugar, 50.0 kg of fructose syrup, 0.14 kg of acesulfame potassium, 0.2 kg of aspartame, 50.0 kg of green tea powder, 3.0 kg of soybean polysaccharide, 3.0 kg of citric acid, 1.5 kg of lactic acid, and 1.0 kg of green tea flavor kg, 4.0kg of carbon dioxide, and 467.16kg of purified water.

[0070] Raw material standard:

[0071] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0072] White sugar: in line with the national first-class standard GB317-2006.

[0073] Purified water, lactic acid, citric acid: comply with national standards GB17323-1998, GB2023-2003, GB / T8269-1998.

[0074] The preparation process is shown in Figure 2, and the specific process is as follows:

[0075] 1. Inspection of milk

[0076] a. Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other ...

Embodiment 3

[0091] Embodiment 3, production deployment type aerated sour milk drink

[0092] Formula (according to 1 ton):

[0093] Milk: 100.0 kg, white sugar 60 kg, fructose syrup (63%) 30 kg, pectin 3.0 kg, propylene glycol alginate 1.0 kg, citric acid 1.5 kg, lactic acid 2.0 kg, carbon dioxide 2 kg, add water to 1 ton .

[0094] White sugar: in line with the national first-class standard GB317-2006.

[0095] Purified water, lactic acid, citric acid: comply with national standards GB17323-1998, GB2023-2003, GB / T8269-1998.

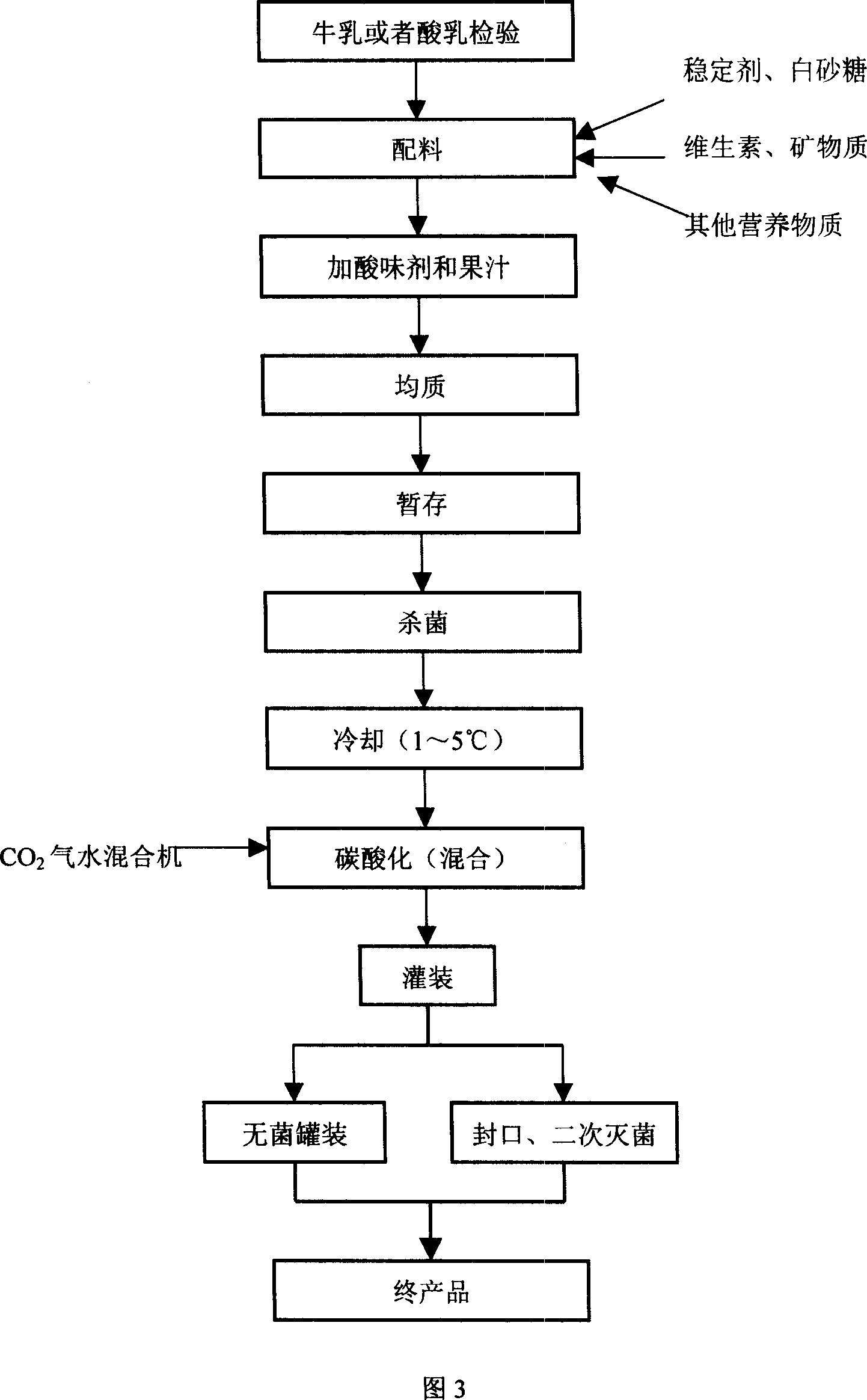

[0096] The preparation process is shown in Figure 3, and the specific process is as follows:

[0097] 1. Inspection of milk

[0098] a. Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators, in line with the national standard GB / T6914-86.

[0099] b. Filtration and cooling: After the raw milk passes through the filter, some larger impurities are removed, and the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com