High heat conducting nylon composite material and preparation method thereof

A nylon composite material and composite material technology are applied in the field of high thermal conductivity nylon composite material and its preparation, which can solve the problems of limited application, low thermal conductivity, poor heat dissipation performance, etc., and achieve high industrial value, high thermal conductivity and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

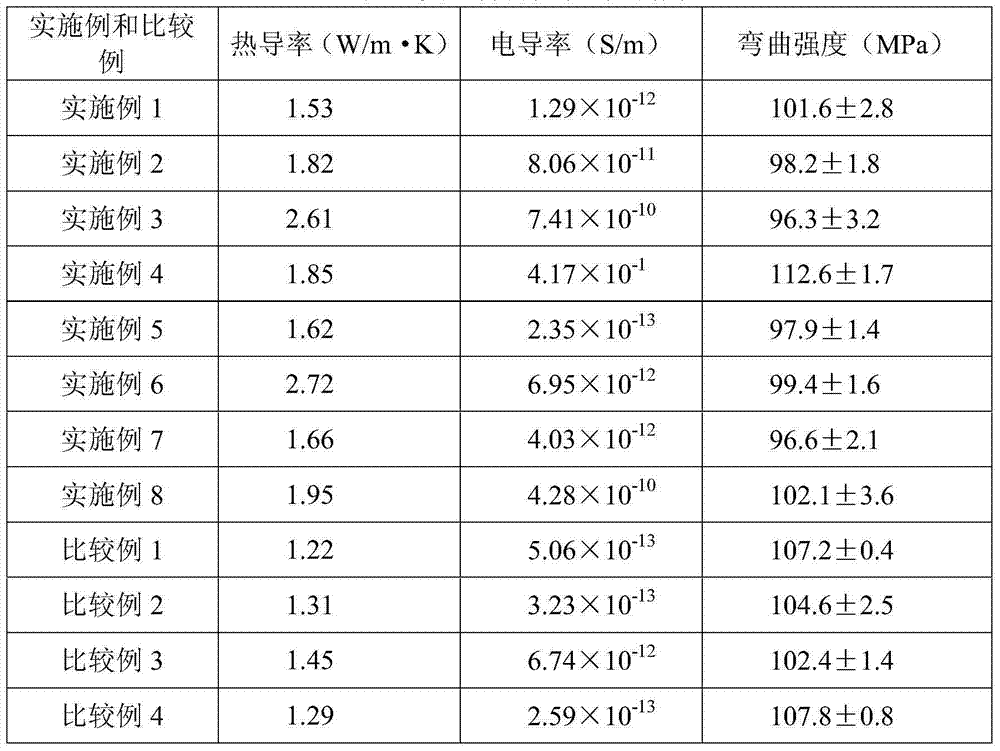

[0023] Weigh 350g of dried PA6 slices, 650g of alumina, 5g of antioxidant 1010 / 168 (according to the ratio of 1:1), 10g of natural graphite flakes, add 10ml of liquid paraffin, mix well and directly add In a twin-screw extruder, melt and knead at a temperature of 245 / 255 / 260 / 260 / 255°C, extrude and granulate, and control the screw speed at 62r / min. After the pellets are dried, they are injection molded into test samples, the injection temperature is 245 / 255 / 260 / 260 / 255°C, the injection pressure is 80MPa, and the mold temperature is 80°C. The performance test results of the obtained composite materials are shown in Table 1.

Embodiment 2

[0025] Implementation method is the same as embodiment 1, and the natural graphite flake is changed into 20g, and other components and quality are constant. The performance test results of the obtained composite materials are shown in Table 1.

Embodiment 3

[0027] Implementation method is the same as embodiment 1, and the natural graphite flake is changed into 50g, and other components and quality are constant. The performance test results of the obtained composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com