Small-sized black phosphorus flakes and preparation method thereof

A technology of small-sized black phosphorus flakes, which is applied in the field of small-sized black phosphorus flakes and its preparation, can solve the problems of low yield of flake black phosphorus, large material size, and small amount of black phosphorus flakes, and achieve uniform size and large size. Controllable, good monodispersity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of small-sized black phosphorus sheet, comprising the steps of:

[0058] Weigh 25 mg of black phosphorus block in a nitrogen-filled glove box, grind it and disperse it into 25 mL of N-methylpyrrolidone, seal to obtain a 1 mg / ml dispersion; ultrasonicate for 3 hours at 1200 W probe ultrasonic power , and then 10 hours of ultrasonication in a water bath with a power of 300W. The entire ultrasonication process is controlled below 277K by an ice bath; then centrifuged at a speed of 7000 rpm for 20 minutes. Small size black phosphorus flakes in N-methylpyrrolidone.

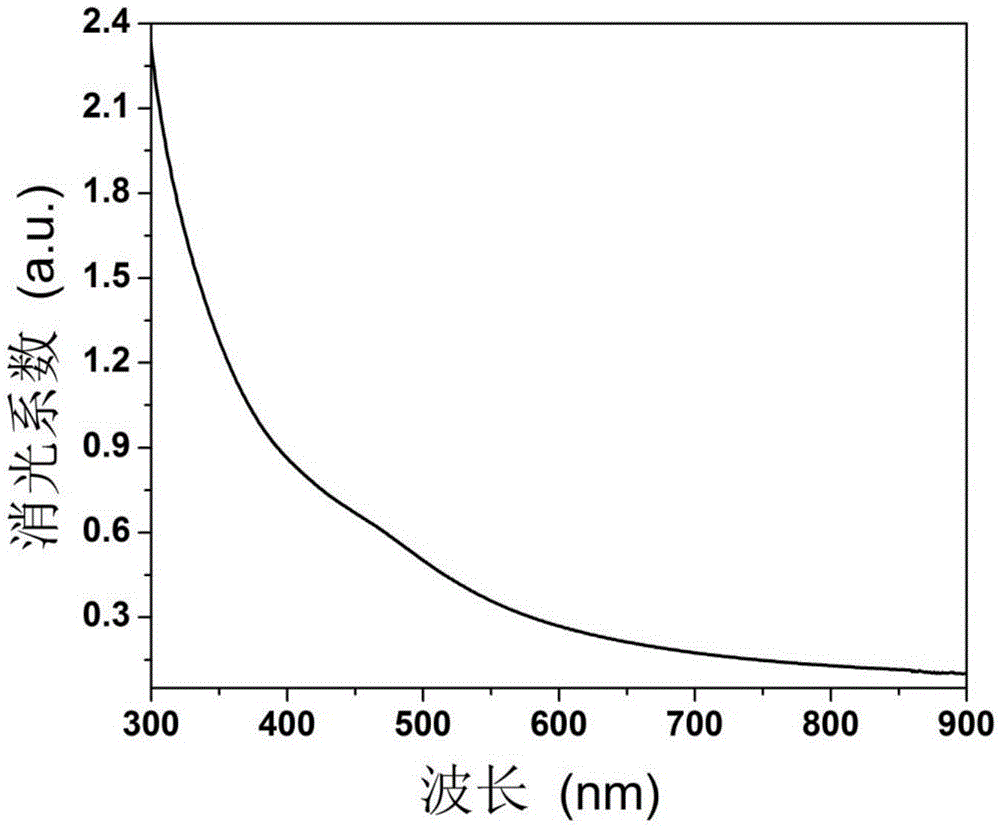

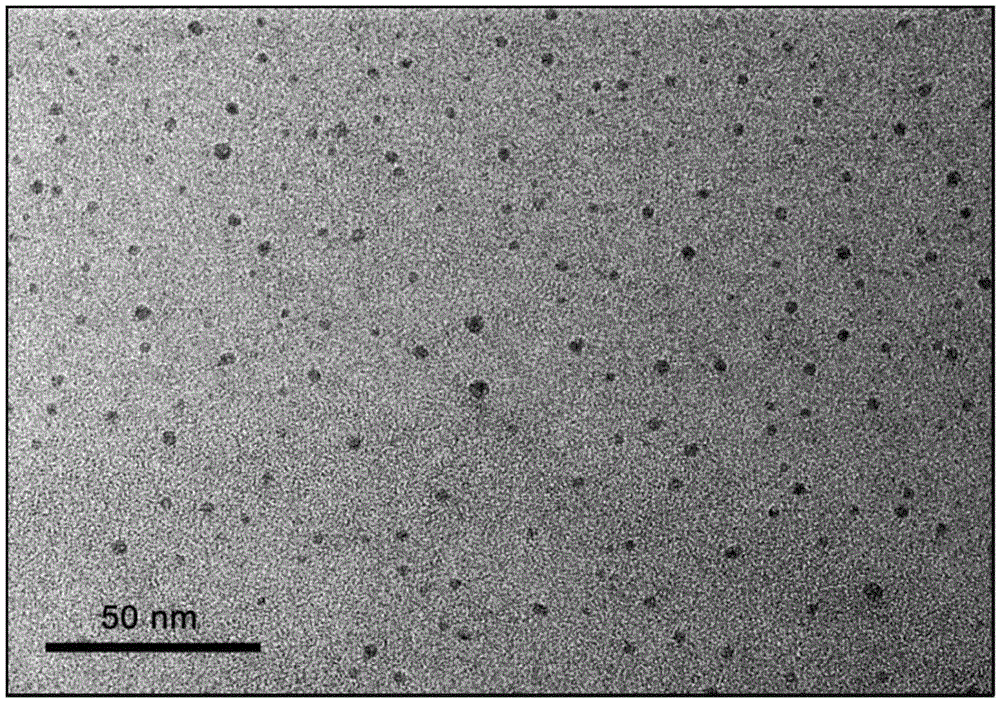

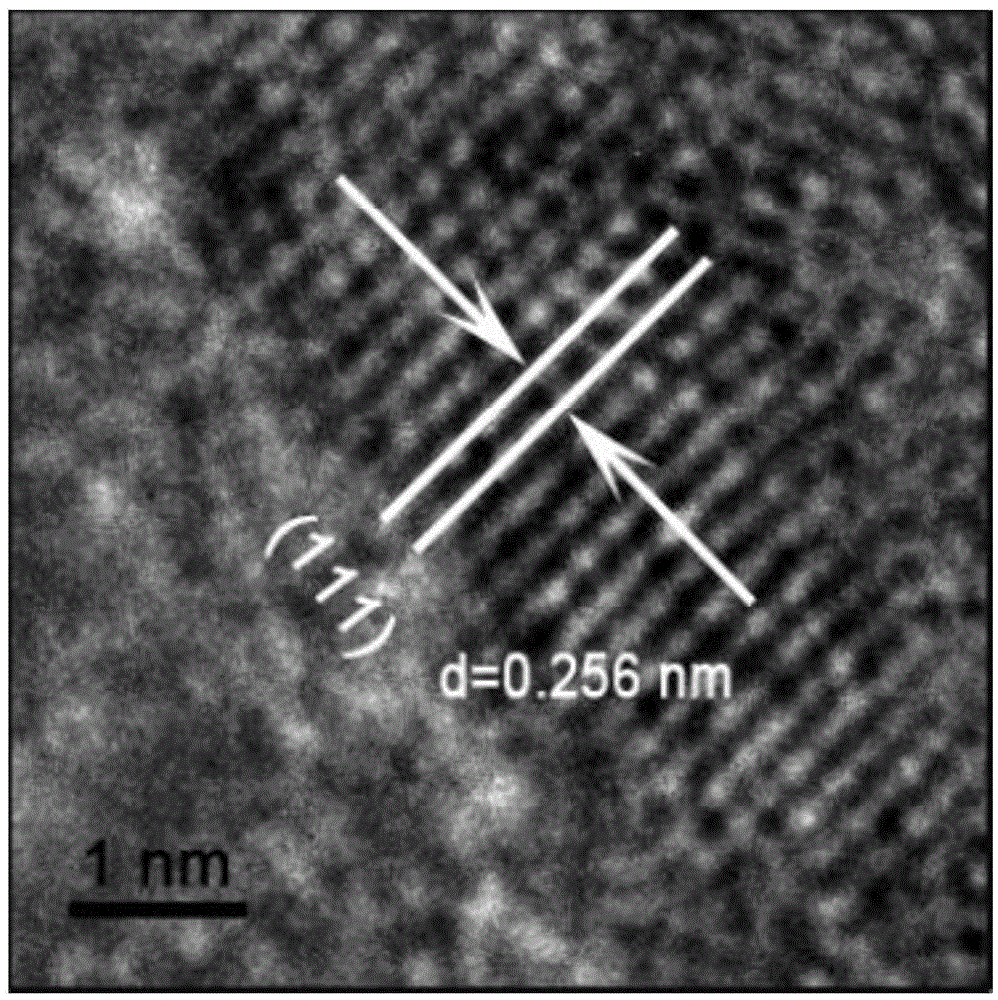

[0059] The product obtained in present embodiment 1 is characterized, and the results are as follows Figure 1 ~ Figure 3 As shown, among them, figure 1 It is the ultraviolet-visible-near-infrared absorption spectrogram of small-sized black phosphorus sheet in N-methylpyrrolidone solution; figure 2 It is a low-magnification transmission electron microscope picture of a small-sized black ...

Embodiment 2

[0061] A preparation method of small-sized black phosphorus sheet, comprising the steps of:

[0062] Weigh 15 mg of black phosphorus block in a nitrogen-filled glove box, grind it and disperse it into 25 mL of N-methylpyrrolidone, seal it, and obtain a 0.6 mg / ml dispersion; Hours, and then followed by 400W power of water bath ultrasonic 8 hours, the whole ultrasonic process is controlled by ice bath to complete below 277K; then centrifuged at 5000 rpm speed, centrifugation time is 20 minutes, take the supernatant, Obtain small size black phosphorus flakes.

Embodiment 3

[0064] A preparation method of small-sized black phosphorus sheet, comprising the steps of:

[0065] Weigh 30 mg of black phosphorus block in a nitrogen-filled glove box, grind and disperse it into 25 mL of dimethyl sulfoxide, seal it to obtain a 1.2 mg / ml dispersion; ultrasonicate under 1000 W probe type ultrasonic power 4 hours, followed by 100W water bath ultrasonication for 12 hours, the entire ultrasonic process is controlled below 277K by ice bath; then centrifuged at 9000 rpm for 10 minutes, the supernatant was taken, Obtain small size black phosphorus flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com