Multifunctional polypropylene composite material and preparation method thereof

A composite material and multifunctional technology, which is applied in the field of multifunctional polypropylene composite materials and its preparation, can solve the problems of not being able to be used as engineering plastics, low low-temperature impact strength, poor flame retardancy, etc., and achieve excellent insulation performance and thermal conductivity. , excellent thermal conductivity, and the effect of ensuring flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Dilute the titanate coupling agent with absolute ethanol at a ratio of 1:1. Under the condition of high-speed stirring, spray the diluted coupling agent on the surface of the magnesium hydroxide filler in the form of mist, keep stirring for 10 minutes, then put it in an oven to dry off the solvent, and cool it for later use;

[0040] (2) Ultrasonicize the graphene nanosheets for 30 minutes, dry and cool for later use;

[0041] (3) Weigh 300g of dried polypropylene pellets, 670g of magnesium hydroxide, 30g of nanographene microflakes, 10g of antioxidant 1010 / 168 (according to the ratio of 1:1), add 5ml of liquid paraffin, and place Mix well in a high-speed mixer;

[0042] (4) Put the pre-mixed uniform material into a twin-screw extruder with an aspect ratio of 25, melt and knead at a temperature of 195 / 200 / 210 / 210 / 205°C, extrude and granulate, and control the screw speed at 62r during the process / min. After the pellets are dried, they are injection molded into te...

Embodiment 2

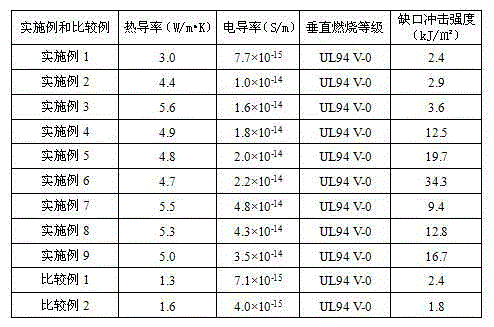

[0044] The implementation method is the same as in Example 1, changing the magnesium hydroxide to 640g, changing the nano-graphene microsheets to 60g, and changing other components and quality into constant. The performance test results of the obtained composite materials are shown in Table 1.

Embodiment 3

[0046] The implementation method is the same as in Example 1, changing the magnesium hydroxide to 610g, changing the nano-graphene microsheets to 90g, and changing other components and quality into constant. The performance test results of the obtained composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com