Method for high yield preparation of graphene by using biologic carbon source material

A bio-carbon source and graphene technology, applied in the direction of graphene, nano-carbon, etc., to achieve high yield, low cost, and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

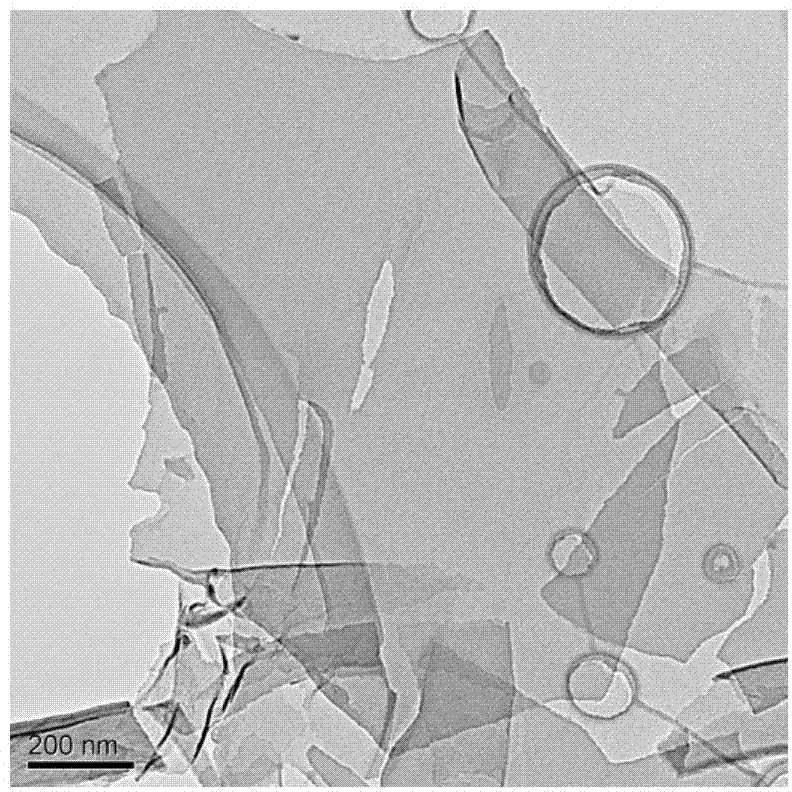

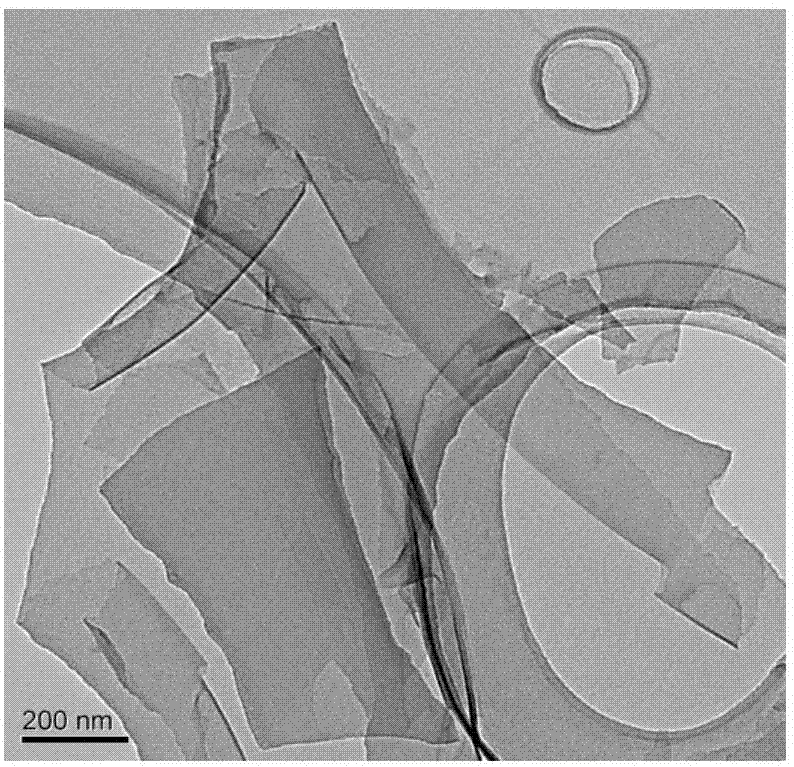

Embodiment 1

[0036] Commercially available cellulose (45% carbon content) was microwaved at 300 W for 10 min. The treated samples were immersed in dilute H at a concentration of 1% at room temperature. 2 SO 4 In the aqueous solution, stir at a constant speed of 30 r / min for 5 hours. After the sample is washed with water, it is placed in a fume hood to dry, and the wind speed is set to 3m / s, and the air volume is 800m 3 / h, keep the ventilated state for 12 hours. The dried sample was mixed with 1% platinum-rhodium alloy (platinum content 12%), then transferred to a tube furnace, fed with nitrogen, and kept for 5 minutes. The tube furnace was heated up to 900°C, heated for 6 hours, and after cooling to room temperature, graphene with obvious exfoliation was obtained. TEM results showed that the obtained graphene sheet thickness was about 3nm, the yield of graphene was 18%, and the purity was 94%.

Embodiment 2

[0038] Commercially available cellulose (45% carbon content) was microwaved at 300 W for 10 min. The treated samples were immersed in 3% dilute H at room temperature. 2 SO 4 In the aqueous solution, stir at a constant speed of 30 r / min for 5 hours. After the sample is washed with water, it is placed in a fume hood to dry, and the wind speed is set to 3m / s, and the air volume is 800m 3 / h, keep the ventilated state for 12 hours. The dried sample was mixed with 12% palladium-iron alloy (19% palladium content) and then transferred to a tube furnace, where hydrogen gas was introduced and kept for 5 minutes. The tube furnace was heated to 1600°C, heated for 3 hours, and cooled to room temperature to obtain graphene with obvious exfoliation. TEM results showed that the obtained graphene sheet thickness was about 5nm, the yield of graphene was 21%, and the purity was 91%.

Embodiment 3

[0040] Commercially available cellulose (45% carbon content) was microwaved at 300 W for 30 min. The treated samples were immersed in dilute H at a concentration of 1% at room temperature. 2 SO 4 In the aqueous solution, stir at a constant speed of 30 r / min for 5 hours. After washing the samples, place them in a fume hood to dry, set the wind speed to 3m / s, and the air volume to 1000m 3 / h, keep the ventilated state for 12 hours. The dried sample was mixed with 2% platinum-rhodium alloy (platinum content 10%), then transferred to a tube furnace, fed with water vapor, and kept for 5 minutes. The tube furnace was heated to 600°C, heated for 8 hours, and after cooling to room temperature, graphene with obvious exfoliation was obtained. TEM results showed that the obtained graphene sheet thickness was about 4nm, the yield of graphene was 16%, and the purity was 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com