Method for preparing graphene from agriculture and forestry waste biomass as carbon source

A technology of agricultural and forestry waste and biomass, applied in the field of graphene preparation, can solve the problems that hinder the large-scale industrial production of graphene, harsh preparation conditions, high production cost, etc., achieve large-scale industrial production, simple preparation process, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is accomplished by the following steps:

[0042] (1) Hydrothermal carbonization of agricultural and forestry waste biomass: crush fir bark into powder, take 3g and add it to a stainless steel reactor filled with 50mL deionized water, put it into a box furnace, react at 180°C for 20h, and cool the reactor naturally Finally, the sample was taken out, washed with ionized water and ethanol successively until the filtrate was colorless, and the filtered product was dried in an oven at 100°C for 12 hours to obtain biochar.

[0043] (2) Alkali exfoliation, graphitization: Grind the obtained biochar and potassium hydroxide in an agate crucible for 30 minutes according to the ratio of potassium hydroxide / biological charcoal to 3:1 (mass ratio), and then transfer to nickel In the crucible, put it into a tube furnace, feed high-purity nitrogen as a protective gas, and the intake flow rate is 300 sccm. Raise to 400°C at a heating rate of 5°C / min, keep at this tempe...

Embodiment 2

[0048] The difference between this example and Example 1 is that the final temperature of the heating and calcination in step (2) is changed from 900°C to 1000°C.

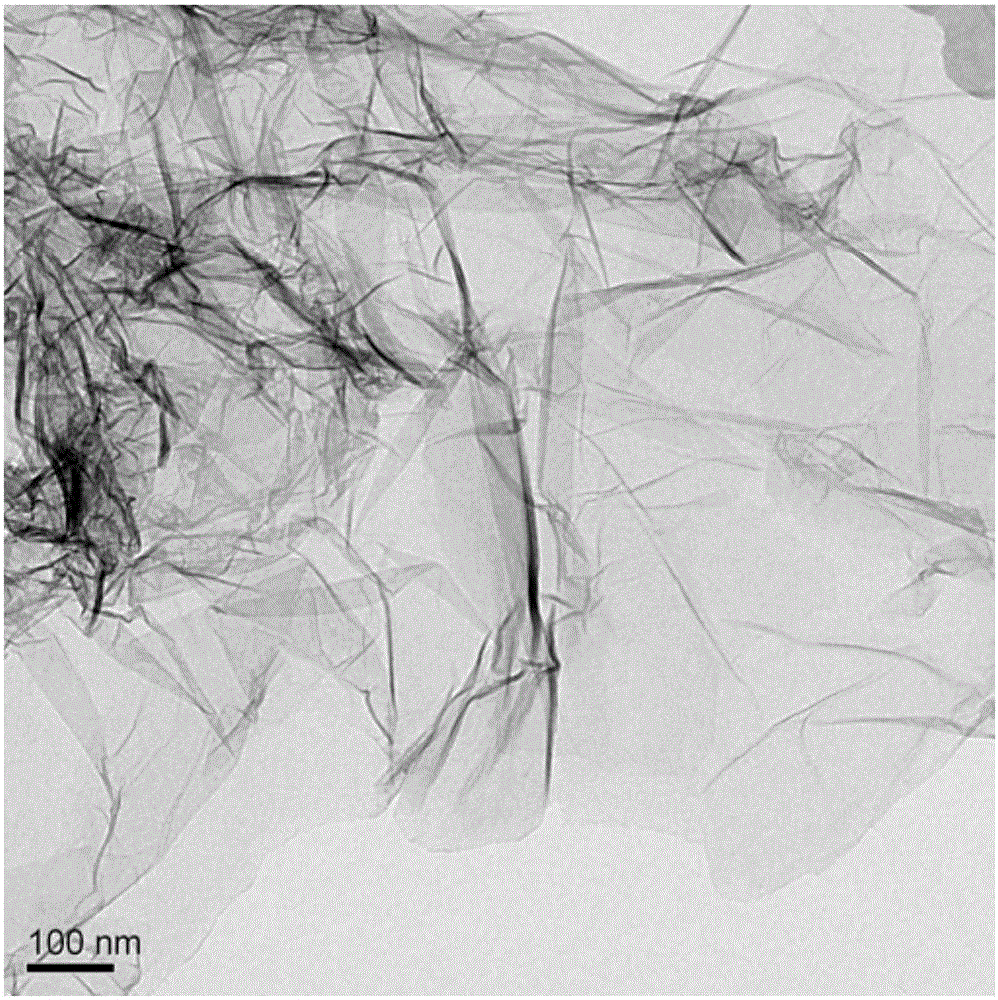

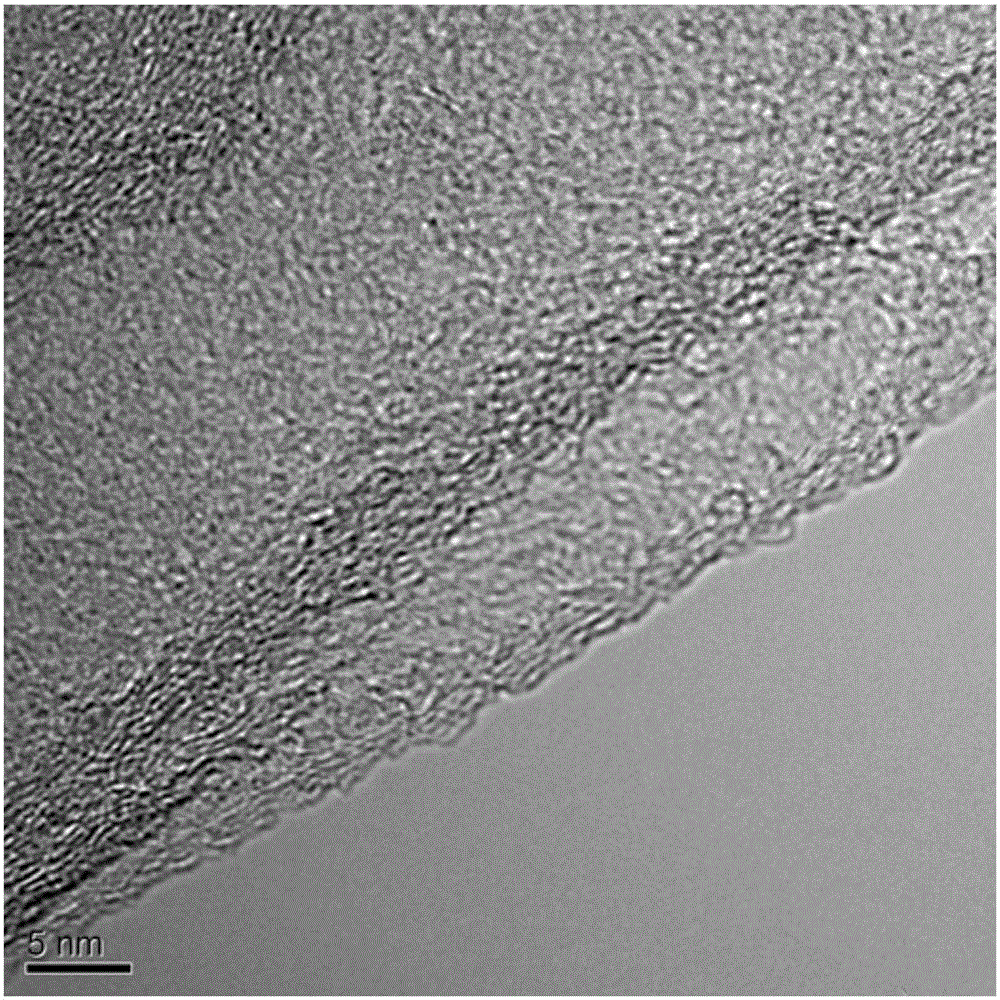

[0049] The transmission electron microscope and the high-resolution transmission electron microscope photo of the few-layer graphene prepared in this embodiment 2 are similar to the photos of the sample in embodiment 1, respectively as figure 1 , as shown in 2. TEM results show that the number of few-layer graphene prepared in Example 2 is about 5-12 layers, the yield is 48%, and the purity is 99%.

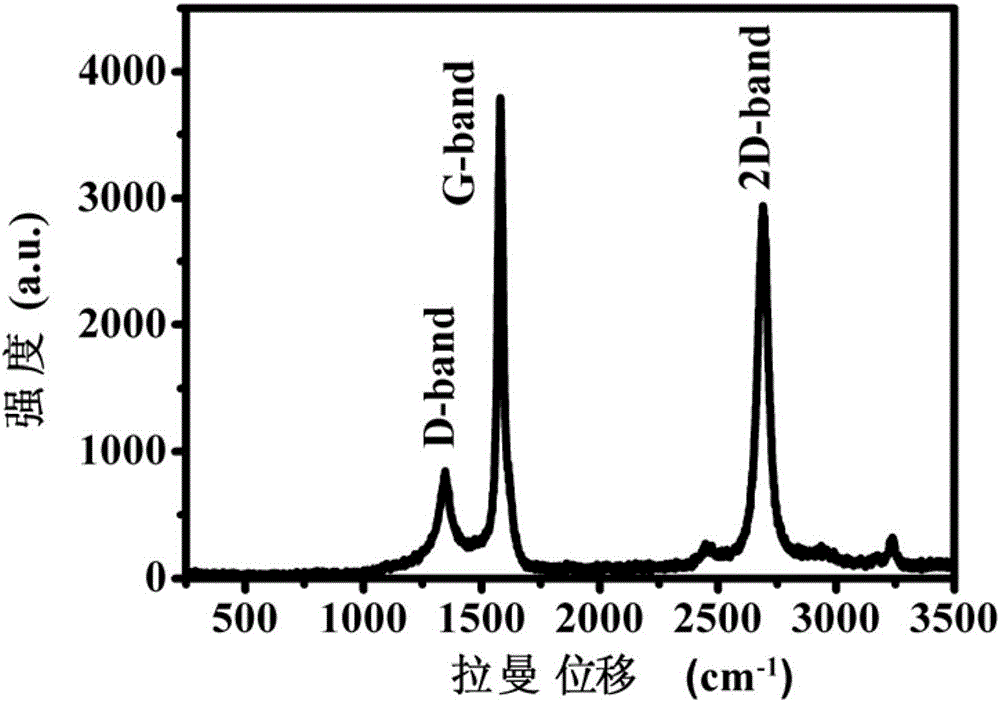

[0050] The Raman spectrogram of the few-layer graphene prepared in this embodiment 2 is similar to that of the sample of embodiment 1, as image 3 As shown, the intensity ratio I of G peak and D peak G / I D It is 5.9, showing a strong degree of graphitization, and the existence of 2D peaks further illustrates that the prepared product is few-layer graphene.

Embodiment 3

[0052] The difference between this example and Example 1 is that the final temperature of the heating and calcination in step (2) is changed from 900°C to 800°C.

[0053] The transmission electron microscope and the high-resolution transmission electron microscope photo of the few-layer graphene prepared in this embodiment 3 are similar to the photos of the sample in embodiment 1, as figure 1 , as shown in 2. TEM results show that the few-layer graphene prepared in Example 3 has about 5 to 11 layers, the yield is 48%, and the purity is 99%.

[0054] The Raman spectrogram of the few-layer graphene prepared in this embodiment 3 is similar to that of the sample in embodiment 1, as image 3 shown. The intensity ratio I of G peak and D peak G / I D It is 5.6, showing a strong degree of graphitization, and the existence of 2D peaks further illustrates that the prepared product is few-layer graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com