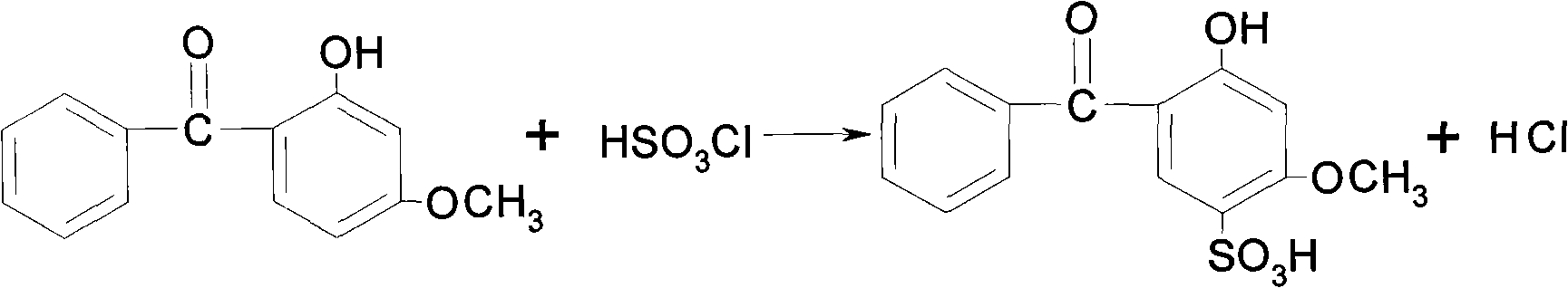

Method for producing 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid

A technology of methoxybenzophenone and sulfonic acid benzophenone, which is applied in the field of water-soluble ultraviolet absorbers, can solve the problems of potential safety hazards, high environmental protection pressure and high solvent residues in product quality, and achieves economic benefits and high efficiency. Significant environmental benefits, improved safety performance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Crude:

[0025] Put 100 kg of qualified 2-hydroxy-4-methoxybenzophenone, 50 kg of chlorosulfonic acid, 100 kg of dimethyl carbonate, and 10 kg of water into the crude product reaction kettle for reaction, and the temperature is controlled at 23-25°C , Insulated for 18 hours to obtain crude BP-4.

[0026] refined:

[0027] Dissolve 100 kg of crude BP-4 in a mixed solvent of 200 kg of dimethyl carbonate, 50 kg of higher aliphatic alcohol and 10 kg of water, recrystallize, and separate the solid-liquid phase to obtain solid phase BP-4. The product yield is 92.1%, and the product purity is 99.5%.

Embodiment 2

[0029] Crude:

[0030] Put 200 kg of qualified 2-hydroxy-4-methoxybenzophenone boutique, 250 kg of chlorosulfonic acid, 1000 kg of dimethyl carbonate, and 100 kg of water into the crude product reaction kettle for reaction, and the temperature is controlled at 30-32 °C, heat preservation reaction for 15 hours to obtain the crude product of BP-4.

[0031] refined:

[0032] Dissolve 200 kg of crude BP-4 in a mixed solvent of 1,000 kg of dimethyl carbonate, 200 kg of higher alcohol, and 30 kg of water, recrystallize, separate the solid-liquid phase, and obtain solid phase BP-4. The product yield is 92.3%, and the product purity is 99.7%.

Embodiment 3

[0034] Crude:

[0035] Put 100 kg of qualified 2-hydroxy-4-methoxybenzophenone boutique, 200 kg of chlorosulfonic acid, 200 kg of dimethyl carbonate, and 50 kg of water into the crude product reaction kettle for reaction, and the temperature is controlled at 36-38 °C, heat preservation reaction for 20 hours to obtain the crude product of BP-4.

[0036] refined:

[0037] Dissolve and recrystallize 100 kg of BP-4 crude product in a mixed solvent of 250 kg of dimethyl carbonate, 150 kg of higher alcohol and 50 kg of water, and separate the solid-liquid phase to obtain solid phase BP-4 fine product. The product yield is 92%, and the product purity is 99.6%.

[0038] The crude product of BP-4 obtained in the present invention refers to: the purity of BP-4 is 90-95%; the refined product refers to the purity of BP-4 above 99%.

[0039] The BP-4 fine product obtained by the present invention has the following technical indicators:

[0040] technical indicators

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com