Modified macromolecular combined corrosion inhibitor and preparation method and application thereof

A polymer and corrosion inhibitor technology, applied in the chemical industry, can solve the problems of environmental pollution, high price, high toxicity, etc., and achieve the effect of easy storage, low cost and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

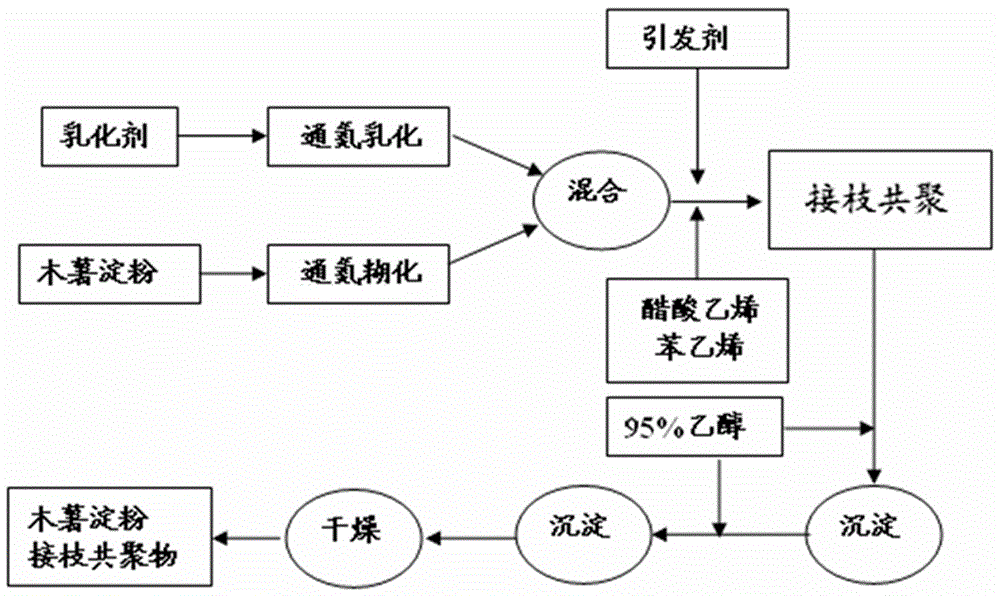

[0024] The preparation method of the modified polymer composite corrosion inhibitor of the present invention comprises the following specific steps:

[0025] A, raw material preparation: prepare cassava starch-vinyl acetate-styrene graft copolymer for subsequent use, prepare pickling solution, sodium lignosulfonate, potassium sorbate, ethylene glycol for subsequent use;

[0026] B. Preparation: Add tapioca starch-vinyl acetate-styrene graft copolymer, sodium lignosulfonate, potassium sorbate, and ethylene glycol into the pickling solution according to the ratio of raw materials, stir and mix evenly to obtain the target product.

[0027] The specific implementation method is as follows:

[0028] A. Add a certain amount of tapioca starch into a 250mL three-necked flask, add 100mL distilled water, and pass N in a constant temperature water bath. 2 Stir and gelatinize for 0.5h, the gelatinization temperature is 70-80°C, cool;

[0029] B. Add vinyl acetate and styrene in the mete...

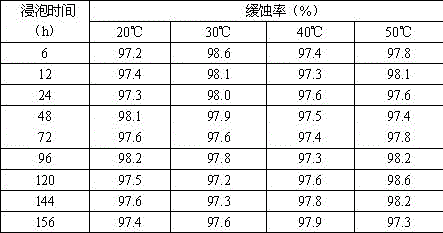

Embodiment 1

[0033] Embodiment 1——The preparation of tapioca starch-vinyl acetate-styrene graft copolymer

[0034] The tapioca starch-vinyl acetate-styrene graft copolymer is composed of Ce(SO 4 ) 2 As an initiator with vinyl acetate and styrene, where:

[0035] a. Add 10g of tapioca starch into a 250mL three-neck flask, add 100mL of distilled water, and pass N in a constant temperature water bath at 75°C 2 Stir and gelatinize for 0.5h, the gelatinization temperature is 70~80°C, cool;

[0036] b. Add 1:2 vinyl acetate and styrene, stir for 20min, then add 10gCe(SO 4 ) 2 , slowly drop 20ml of 1.5mol / L NaHSO 3 solution, and continued to stir for 250 min. After the reaction was terminated, the reaction solution was cooled to room temperature and washed with anhydrous C 2 h 5 OH precipitates the product. After filtering and washing, dry in a vacuum oven at 50°C to constant weight to obtain the grafted crude product.

[0037] c. Weigh 16.5 g of the grafted crude product, use a Soxhlet...

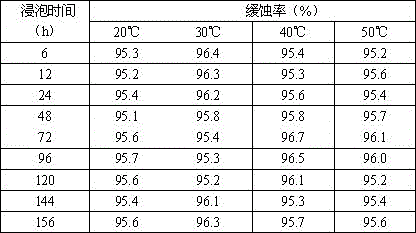

Embodiment 2

[0038] Embodiment 2——The preparation of tapioca starch-vinyl acetate-styrene graft copolymer

[0039] The tapioca starch-vinyl acetate-styrene graft copolymer is composed of (NH 4 ) 2 S 2 o 8 As an initiator with vinyl acetate and styrene, where:

[0040] a. Add 15g of tapioca starch into a 250mL three-neck flask, add 100mL of distilled water, and pass N in a constant temperature water bath at 80°C 2 Stir and gelatinize for 0.6h, the gelatinization temperature is 70~80°C, cool;

[0041] b. Add 1:2 vinyl acetate and styrene, stir for 20min, then add 15gCe(SO 4) 2 , slowly drop 25ml of 2.0mol / L NaHSO 3 solution, and continued to stir for 300 min. After the reaction was terminated, the reaction solution was cooled to room temperature and washed with anhydrous C 2 h 5 OH precipitates the product. After filtering and washing, dry in a vacuum oven at 50°C to constant weight to obtain the grafted crude product.

[0042] c. Weigh 22 g of the grafted crude product, use a So...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com