Production process method of aluminum-coated wooden building template

A technology for building formwork and production process, which is applied in the joining of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problems of increased construction technical difficulty, high cost of aluminum alloy formwork, low compressive strength, etc. No on-site sawing, overcoming expensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

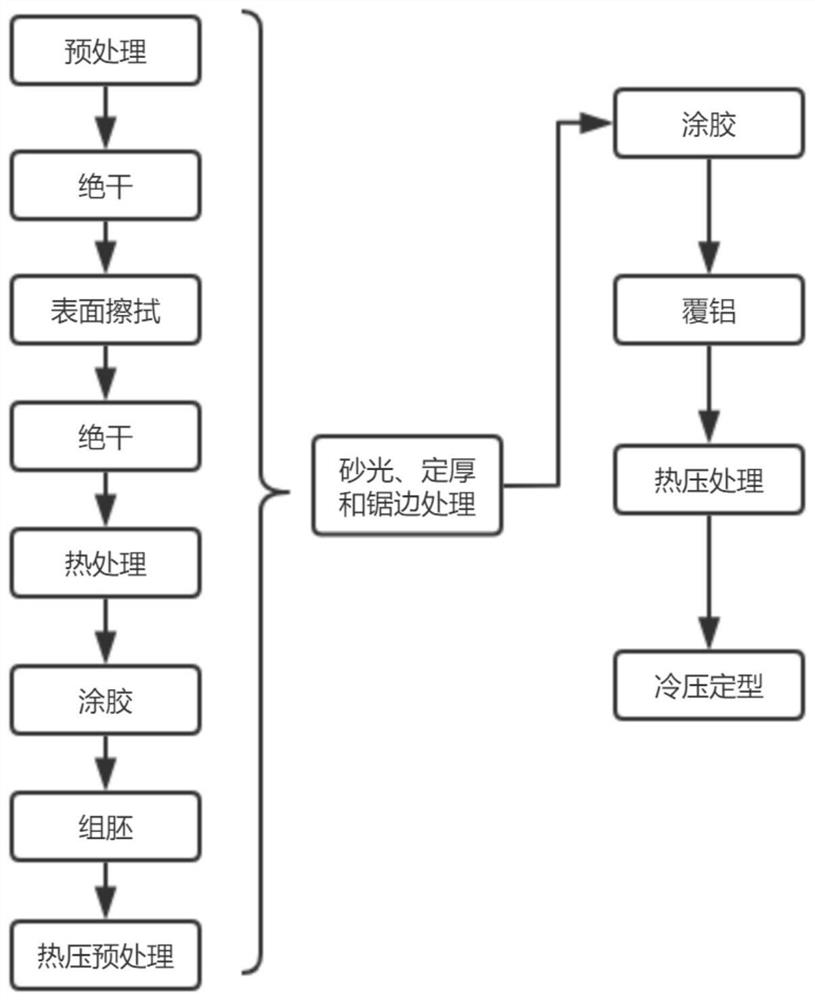

[0026] refer to figure 1 , a method for producing aluminum-clad wooden building formwork, comprising the following steps:

[0027] S1, pretreating the wooden veneer, placing the pretreated wooden veneer in a ventilated drying box for dry treatment;

[0028] S2, taking out the wooden veneer after the drying treatment in S1 after soaking it in a flame retardant for 24 hours, and wiping the surface of the wooden veneer;

[0029] S3. Put the wooden veneer after the surface wiping treatment in S2 into a ventilated drying box, set the temperature at 75-85° C., and dry to absolutely dry;

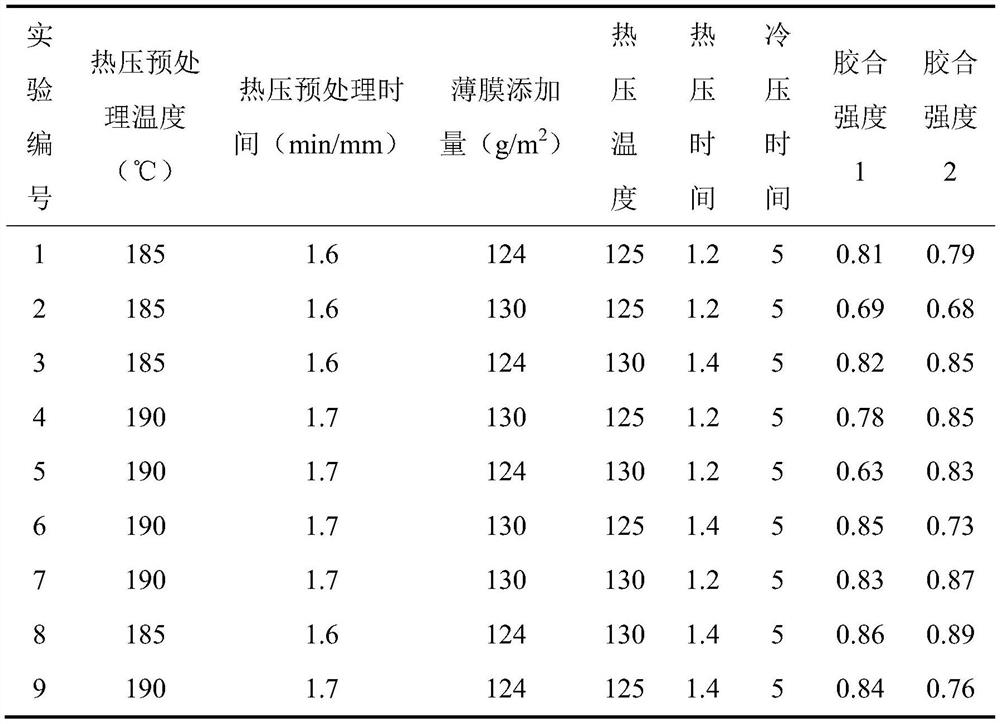

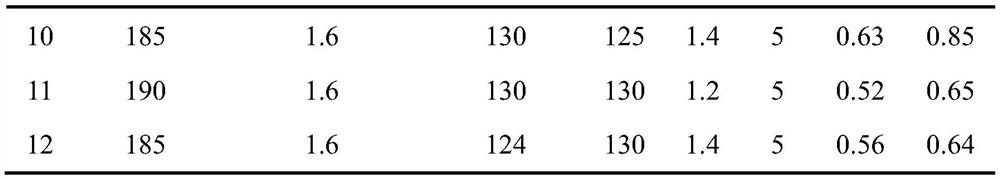

[0030] S4. Carry out heat treatment to the wooden veneer after the absolute dry treatment in S3, carry out glue coating treatment on the surface of the wooden veneer after the heat treatment, then carry out embryo formation with 5 wooden veneers after the glue coating treatment, heat the rough embryo Press pretreatment, set the temperature at 185°C, 1.6min / mm, sanding, thickness-setting and sawin...

Embodiment 2

[0036] Embodiment 2: According to the steps and methods in Embodiment 1, but different from Embodiment 1, the hot-pressing pretreatment temperature is set to 190 ° C, and the experimental results are as follows in Table 1;

Embodiment 3

[0037] Embodiment 3: according to the step method in embodiment 1, but different from embodiment 1 is that setting film addition amount is 130, and experimental result is as follows table 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com